PRM

®

7

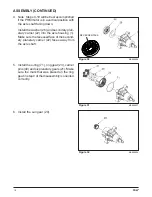

NOTE: Any servicing dealer attempting

a warranty repair must have prior ap

-

proval before conducting maintenance

of a Hydro-Gear

®

product unless the

servicing dealer is a current Authorized

Hydro-Gear Service Center.

EXTERNAL MAINTENANCE

Regular external maintenance of the PRM

®

should include the following:

1. Check the vehicle operator’s manual for

the recommended load ratings. Insure

the current application does not exceed

load rating.

2.

Check fluid level in drive system reservoir

in accordance with vehicle manufacturer’s

recommendations.

3. Inspect all external plumbing for possible

leaks or loose fittings.

4. Insure the reservoir is free of contaminants

and is properly vented.

5. Remove any obstructions (grass clippings,

leaves or dirt).

6. Inspect the vehicle control linkage to the

brake arm on the PRM motor.

SERVICE AND MAINTENANCE

PROCEDURES

NOTE: Damage to PRM’s may result

from external or internal contamination:

Heat from excess debris or lack of lu

-

brication and over-pressurization of the

product. Follow guidelines established

in this manual and the vehicle manufac

-

turer’s recommendations.

Note: “Any and all Hydro-Gear components

removed and replaced during service are

recyclable.”

SECTION 4. SERVICE AND MAINTENANCE

Cleanliness is a key factor in the successful

repair of PRM’s. Thoroughly clean all exposed

surfaces prior to any type of maintenance. Clean-

ing of all parts by using a solvent wash and air

drying is usually adequate. As with any precision

equipment, all parts must be kept free of foreign

material and chemicals. Protect all exposed seal-

ing areas and open cavities from damage and

foreign material.

Upon removal, all seals, O-rings, and gaskets

should be replaced. During installation, lightly

lubricate all seals, O-rings, gaskets with clean

petroleum jelly prior to assembly. Also, protect

the inner diameter of seals by covering the shaft’s

machined features with plastic wrap or equivalent.

Remove plastic wrap after seal is installed.

FLUIDS

The fluids used in Hydro-Gear products have

been carefully selected, and only equivalent, or

better products should be substituted.

Typically, an engine oil with a minimum rating of

9.0 cSt (55 SUS) at 230° F (110° C) maximum

operating temperature and an API classification

of SJ/ CD is allowed. Refer to the vehicle manu-

facturer for recommended oil.

“All fluids should be handled and disposed of

according to local, state, and federal regula

-

tions.”

FLUID VOLUME AND LEVEL

Certain situations may require additional fluid to

be added or even replaced. Refer to the vehicle

manufacturer’s recommendations for the proper

fill location and level.

FLUID CHANGE

In the event of oil degradation, oil addition or

change may alleviate certain performance

problems. Refer to the vehicle manufacturer’s

recommended oil change frequency.

In the event of oil contamination or hydraulic sys-

tem component failure, a complete teardown and

inspection of the PRM will be required.

Содержание HGM-H Series

Страница 1: ...BLN 0043 January 2018 HGM H Series Motor Service and Repair Manual ...

Страница 25: ...24 HGM H HGM H MOTOR EXPLODED VIEW ...

Страница 29: ...HEMTM Series Motor Service and Repair Manual BLN 0083 January 2018 ...

Страница 52: ...PRM MOTOR Service and Repair Manual ...

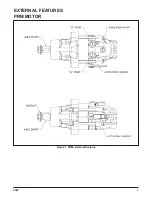

Страница 56: ...PRM 3 EXTERNAL FEATURES PRM MOTOR Figure 1 PRM External Features ...

Страница 77: ...24 PRM SECTION 8 PARTS LIST Figure 48 MA04K030 ...

Страница 81: ...BLN 50231 January 2018 BDP 10L PL Hydrostatic Pump Service and Repair Manual ...

Страница 82: ......

Страница 83: ......

Страница 84: ......

Страница 85: ......

Страница 86: ......

Страница 87: ......

Страница 88: ......

Страница 89: ......

Страница 90: ......

Страница 91: ......

Страница 92: ......

Страница 95: ......

Страница 96: ......

Страница 97: ......

Страница 98: ......

Страница 99: ......

Страница 100: ...HGM 12P LSHT Wheel Motor Service and Repair Manual BLN 52197 January 2018 ...

Страница 102: ...2 Exploded view HGM P ...

Страница 117: ...HGM E LSHT Wheel Motor Service and Repair Manual BLN 52198 January 2018 ...

Страница 140: ...P Series Hydrostatic Pumps Service and Repair Manual BLN 0093 June 2018 PC PJ PK PW PY PR PG PE ...

Страница 144: ...2 P Series EXTERNAL FEATURES PC SERIES Figure 1 PC Pump with Standard Charge Pump ...

Страница 146: ...4 P Series EXTERNAL FEATURES PJ SERIES Figure 3 PJ Pump with Standard Charge Pump ...

Страница 147: ...5 P Series Figure 4 PK Pump With Standard Charge Pump EXTERNAL FEATURES PK SERIES ...

Страница 176: ...34 PC Series Figure 16 PC Pump BOXES INDICATE ITEMS INCLUDED IN Kit Number ...

Страница 192: ...52 PG PE Series Figure 17 PG PE Pump BOXES INDICATE ITEMS INCLUDED IN KITS Kit Number ...

Страница 208: ...70 PJ Series Figure 17 PJ Pump BOXES INDICATE ITEMS INCLUDED IN Kit Number ...

Страница 224: ...88 PK Series Figure 17 PK Pump BOXES INDICATE ITEMS INCLUDED IN Kit Number ...

Страница 240: ...106 PR Series Figure 17 PR Pump BOXES INDICATE ITEMS INCLUDED IN KITS Kit Number ...

Страница 257: ...124 PW PY Series Figure 17 PW PY Pump 85 Overhaul Seal Kit BOXES INDICATE ITEMS INCLUDED IN KITS Kit Number ...

Страница 261: ...HGM C LSHT Wheel Motor Service and Repair Manual BLN 52690 January 2018 ...