HEM

TM

7

Some of the service procedures presented on

the following pages can be performed while the

motor is mounted on the machine. Any repair

procedures as mentioned in the repair section

of this manual must be performed after the mo-

tor has been removed from the machine. The

motor should be thoroughly cleaned before any

service procedures are performed.

FLUIDS

The fluids used in Hydro-Gear

products have

been carefully selected, and only equivalent,

or better products should be substituted.

Hydraulic oil in the range of ISO 32 to ISO 68

has been approved for the HEM. At the peak

operating temperature, hydraulic oil viscosity

is required to be a minimum of 9 cSt [55 SUS].

“All fluids should be handled and disposed

of according to local, state, and federal

regulations.”

FLUID VOLUME AND LEVEL

Certain situations may require additional fluid

to be added or even replaced. Refer to the

machine manufacturer’s recommendations for

the proper fill location and level.

FLUID CHANGE

In the event of oil degradation, oil addition or

change may alleviate certain performance

problems. Refer to the machine manufac-

turer’s recommended oil change frequency.

In the event of oil contamination or hydrau-

lic system component failure, a complete

teardown and inspection of the HEM will be

required.

SERVICE AND MAINTENANCE

NOTE: Any servicing dealer attempting

a warranty repair must have prior ap-

proval before conducting maintenance

of a Hydro-Gear

®

product unless the

servicing dealer is a current Authorized

Hydro-Gear Service Center.

EXTERNAL MAINTENANCE

Regular external maintenance of the HEM

TM

should include the following:

1. Check the machine operator’s manual for

the recommended load ratings. Insure

that the current application does not

exceed load rating.

2. Check fluid level in drive system reservoir

in accordance with the machine manufac-

turer’s recommendations.

3. Inspect all external plumbing for possible

leaks or loose fittings.

4. Insure the reservoir is free of contaminants

and is properly vented.

5. Remove any obstructions (leaves or dirt).

SERVICE AND MAINTENANCE

PROCEDURES

NOTE: Damage to the HEMs may result

from external or internal contamination:

Heat from excess debris or lack of lubrica-

tion and over-pressurization of the prod-

uct. Follow guidelines established in this

manual and the machine manufacturer’s

recommendations.

Note: Anytime the HEM is drained of

oil the motor case should be filled (150

milliliters) prior to system startup.

Содержание HGM-H Series

Страница 1: ...BLN 0043 January 2018 HGM H Series Motor Service and Repair Manual ...

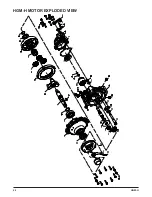

Страница 25: ...24 HGM H HGM H MOTOR EXPLODED VIEW ...

Страница 29: ...HEMTM Series Motor Service and Repair Manual BLN 0083 January 2018 ...

Страница 52: ...PRM MOTOR Service and Repair Manual ...

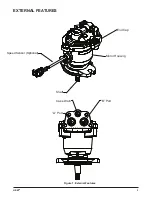

Страница 56: ...PRM 3 EXTERNAL FEATURES PRM MOTOR Figure 1 PRM External Features ...

Страница 77: ...24 PRM SECTION 8 PARTS LIST Figure 48 MA04K030 ...

Страница 81: ...BLN 50231 January 2018 BDP 10L PL Hydrostatic Pump Service and Repair Manual ...

Страница 82: ......

Страница 83: ......

Страница 84: ......

Страница 85: ......

Страница 86: ......

Страница 87: ......

Страница 88: ......

Страница 89: ......

Страница 90: ......

Страница 91: ......

Страница 92: ......

Страница 95: ......

Страница 96: ......

Страница 97: ......

Страница 98: ......

Страница 99: ......

Страница 100: ...HGM 12P LSHT Wheel Motor Service and Repair Manual BLN 52197 January 2018 ...

Страница 102: ...2 Exploded view HGM P ...

Страница 117: ...HGM E LSHT Wheel Motor Service and Repair Manual BLN 52198 January 2018 ...

Страница 140: ...P Series Hydrostatic Pumps Service and Repair Manual BLN 0093 June 2018 PC PJ PK PW PY PR PG PE ...

Страница 144: ...2 P Series EXTERNAL FEATURES PC SERIES Figure 1 PC Pump with Standard Charge Pump ...

Страница 146: ...4 P Series EXTERNAL FEATURES PJ SERIES Figure 3 PJ Pump with Standard Charge Pump ...

Страница 147: ...5 P Series Figure 4 PK Pump With Standard Charge Pump EXTERNAL FEATURES PK SERIES ...

Страница 176: ...34 PC Series Figure 16 PC Pump BOXES INDICATE ITEMS INCLUDED IN Kit Number ...

Страница 192: ...52 PG PE Series Figure 17 PG PE Pump BOXES INDICATE ITEMS INCLUDED IN KITS Kit Number ...

Страница 208: ...70 PJ Series Figure 17 PJ Pump BOXES INDICATE ITEMS INCLUDED IN Kit Number ...

Страница 224: ...88 PK Series Figure 17 PK Pump BOXES INDICATE ITEMS INCLUDED IN Kit Number ...

Страница 240: ...106 PR Series Figure 17 PR Pump BOXES INDICATE ITEMS INCLUDED IN KITS Kit Number ...

Страница 257: ...124 PW PY Series Figure 17 PW PY Pump 85 Overhaul Seal Kit BOXES INDICATE ITEMS INCLUDED IN KITS Kit Number ...

Страница 261: ...HGM C LSHT Wheel Motor Service and Repair Manual BLN 52690 January 2018 ...