www.h-v-c.com

Symptom

Possible causes

Action

Damper closed and cannot be reset open

Thermal link has activated

Check thermal link by comparing with figures 1 and 2, page 3

If activated thermal links must be replaced

See below: 'Thermal link replacement'

Handle mechanism not engaged

on thermal link correctly

Check machine screw in spindle cap is tightly screwed down

Test handle hard to pull

Lack of lubrication

Remove handle mechanism, sparingly apply viscous lubricant to

region of spindle where handle slides, refit handle mechanism

See below: ‘Handle mechanism removal and replacement’

Damper blade not fully opening or closing

Damper motion obstructed by

debris

Remove debris.

Ensure no damage has been caused to damper.

Handle mechanism fitted

incorrectly

Remove and refit mechanism correctly

See below: Handle mechanism removal and replacement

procedure'

Ensure no damage has been caused to damper

Damper seized

Lubrication required

See below: 'Lubrication procedure'

Mechanical failure

Contact HVC

Damper blade loose

Mechanical failure

Contact HVC

Installation guide: NCA Series 400 hand operated single blade leakage rated fire damper

Operation and maintenance manual

Page 2 of 3 - Issue A - 03/03/2022

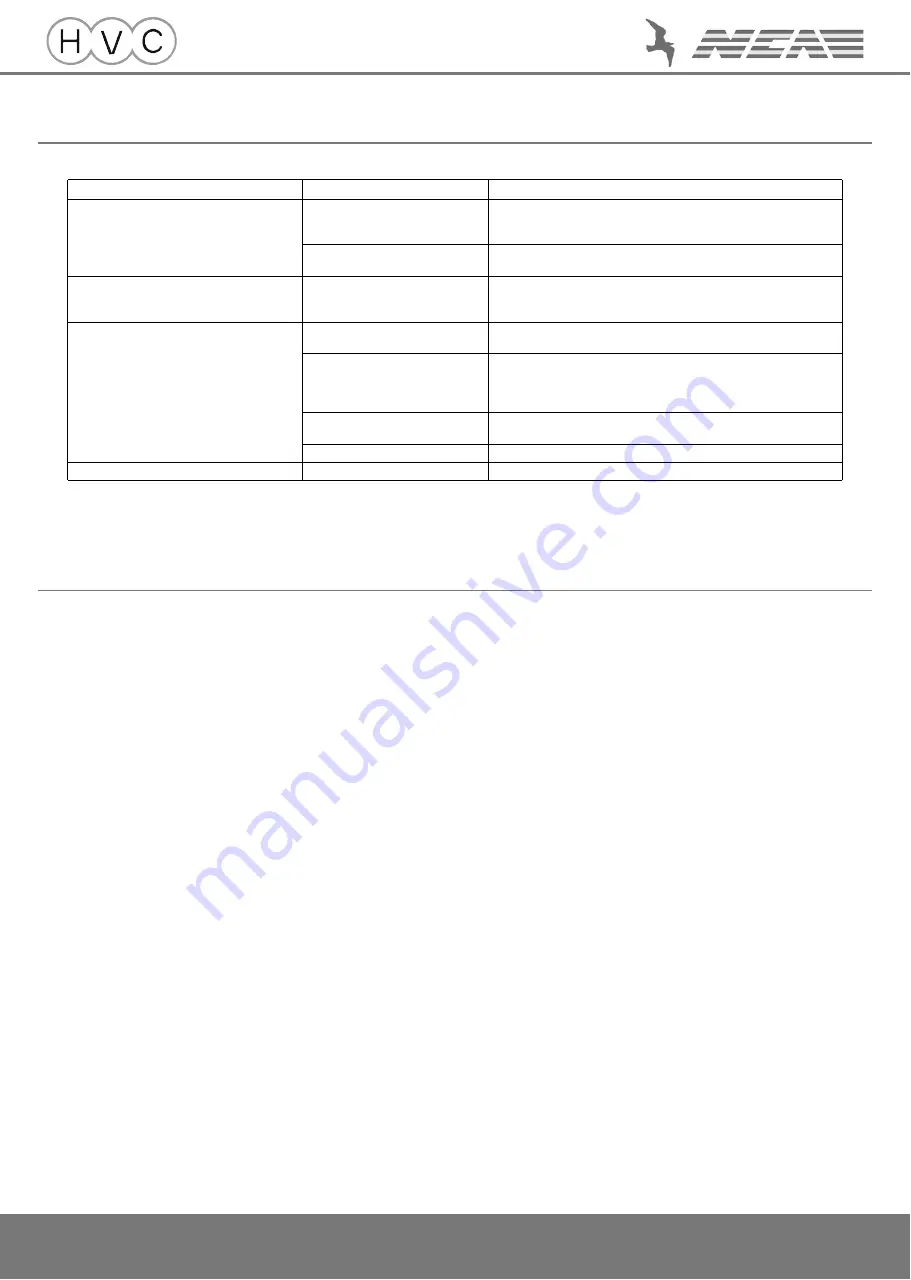

Thermal link replacement

1. Remove handle mechanism as per steps 1 - 3 of ‘Handle

mechanism removal and replacement procedure’ adjacent.

2. Remove activated link (12mm spanner required) and discard.

3. Refit new link ensuring correct temperature rating is used,

68°C (red bulb in link) or 93°C (green bulb in link).

4. Refit handle mechanism as per step 4 of ‘Handle mechanism

removal and replacement procedure’ adjacent.

5. Open damper as per step 8 of the periodic maintenance

procedure.

Troubleshooting

Additional procedures

Handle mechanism removal and replacement

1. Ensure damper is closed (setting handle perpendicular with

damper case).

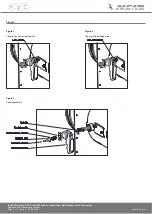

2. Referring to page 3, figure 3 if necessary, unscrew the

machine screw in the shaft end cap (pozi-drive screwdriver

required).

3. Slide spindle cap, compression spring, test handle and setting

handle off shaft.

4. To refit, reverse previous steps, ensuring setting handle is

replaced perpendicular to damper case.

Contact HVC if the above does not solve your problem.

Lubrication

1. Remove access door/s to access the inside of ductwork and

damper blade.

2. Clean damper if required following step 7 of the periodic

maintenance procedure.

3. Apply a small amount of light oil (WD40 spray grease

recommended) directly into the blade axle bushes.

4. Remove any excess oil with a cloth.

5. Conduct a cycle test as per steps 7 and 8 of the periodic

maintenance procedure and observe whether the operation

has improved.