IGSSB-SCSS / SCSS-SL-0108

2

/Chino

A publication of

Hussmann

®

Chino

13770 Ramona Avenue • Chino, California 91710

(909) 628-8942 FAX

(909) 590-4910

(800) 395-9229

Keep this booklet with the case at all times for future reference.

THIS BOOKLET CONTAINS INFORMATION ON:

MODEL DESCRIPTIONS

All models are available in either 48”, 60” lengths.

SCSSSL - Non-refrigerated Summit Cake Self-Service

Bakery Case with 1, or 2 tier merchandising, and rear

signage.

SCSSSL - Refrigerated Summit Cake Self-Service Bakery

Case with 1,or 2 tier merchandising, and rear signage.

Remote unit requires separate condenser unit connection.

Low Temperature Model (SCSSSL-RLL).

SCSSSL -Self-contained refrigerated Summit Cake Self-

Service Bakery Case with 1, or 2 tier merchandising, and

rear signage. Low Temperature Model (SCSSSL-S/CHL).

APPLICATION

These service-type merchandisers have been specifically

designed for bakery departments. The front glass provides

complete product visibility.

The SCSSSL- non-refrigerated model, is designed to

display fresh bakery products that have fast turnover and

require no refrigeration. The SCSSSL- remote, and

SCSSSL- self-contained, refrigerated baker y

merchandisers are designed for use only in air conditioned

stores where temperature and humidity are maintained

at or below 75

°

F dry bulb temperature and 55% relative

humidity.

SHIPPING DAMAGE

All equipment should be thoroughly examined for ship-

ping damage before and during unloading.

This equipment has been carefully inspected at our fac-

tory and the carrier has assumed responsibility for safe

arrival. If damaged, either apparent or concealed, claim must

be made to the carrier.

APPARENT LOSS OR DAMAGE

If there is an

obvious loss or damage

, it must be noted on

the freight bill or express receipt and signed by the carrier’s

agent; otherwise, carrier may refuse claim. The carrier will

supply necessary claim forms.

CONCEALED LOSS OR DAMAGE

When loss or damage

is not apparent until after equipment

is uncrated

, a claim for concealed damage is made. Make

request in writing to carrier for inspection within 15 days,

and retain all packaging. The carrier will supply inspection

General Instructions

Table of Contents

General Instructions ................................................. 2

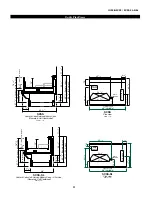

Cut & Plan Views ....................................................... 4

Installation ................................................................. 5

LEVELING .............................................................................................................. 5

Plumbing .................................................................... 6

WASTE OUTLET AND P-TRAP .............................................................................. 6

JOINT TRIM ........................................................................................................... 6

Refrigeration ............................................................. 7

T-STAT LOCATION .................................................................................................. 8

Condensing Unit Installation Requirements ....................................................... 8

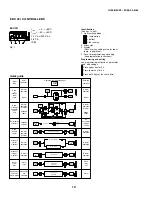

Electrical .................................................................... 9

WIRING COLOR CODE ......................................................................................... 9

ASHRAE COLOR CODE .......................................................................................... 9

User Information ...................................................... 12

STOCKING .............................................................................................................. 12

CASE CLEANING .................................................................................................... 12

NON-GLARE GLASS ............................................................................................... 13

PLEXIGLASS & ACRYLIC CARE .............................................................................. 13

Maintenance .............................................................. 14

ELECTRICAL PRECAUTIONS ................................................................................... 14

14

REPLACING FLUORESCENT LAMPS ....................................................................... 14

Electrical and Refrigeration Specifications ............ 14

TIPS & TROUBLESHOOTING ................................................................................. 14

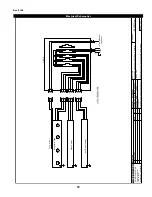

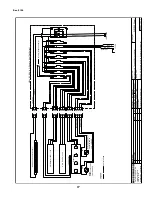

Electrical Schematics ............................................... 15

Appendices ................................................................ 19

APPENDIX A. – Temperature Guidelines ............................................................ 19

APPENDIX B. – Application Recommendations .................................................. 19

APPENDIX C. – Field Recommendations - ......................................................... 19

APPENDIX D. – Recommendations to user - .................................................... 20

Содержание SCSS

Страница 22: ...IGSSB SCSS SCSS SL 0108 22 ...