AIR FILTER

8

17

2

3

1

1

2

3

502 53 07-26

Cylinder

cooling air

In

To carburettor

IMPORTANT!

Stone and concrete dust are the engine's greatest enemy!

Check the condition of the inlet bend and that it seals perfectly

against the carburettor and cylinder cover.

Dust in the inlet bend indicates a serious fault in the filter

system, which must be rectified before the machine is used.

Function

Husqvarna Active Air Filtration

is a filter system that

effectively purifies the air to the engine in

three separate steps

and according to three different purification principles:

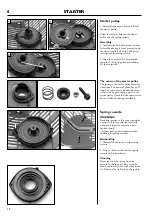

1. Centrifugal cleaning

is the first step in the purification of

the inlet air.

The fins on the flywheel supply the cylinder with cooling air

at the same time as they act as the active part in the centrifugal

cleaning of the engine's inlet air. An inlet nozzle is fitted close to

the fins on the flywheel. The centrifugal force means that large

particles do not follow the curved air currents to the nozzle, but

are thrown to the outside of the nozzle. Only very small dust

particles manage to swing with the air currents to the inlet.

2. Foam plastic filter

is the next level of separation in the

purification process. An air deflector guides and distributes the air

across the whole filter surface, which means that the whole of the

filter is better utilised and is fouled evenly across the surface. The

filter is steeped in oil and is made up of three layers with

different pore sizes.

3. The paper filter

primarily provides effective protection

should the foam plastic filter, on account of inadequate care, lets

dust through.

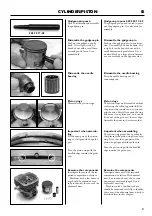

Filter service

1. Centrifugal cleaning

The inlet duct should be inspected and any deposits removed in

connection with filter replacement. Dust from dry cutting is

cleaned off using compressed air Material from wet cutting

normally needs to be scraped off mechanically.

2. Foam plastic filter

New filters are supplied steeped in the correct amount of filter oil.

The replacement frequency is dependent on a number of factors

and therefore cannot be generally stated. Unfortunately there is no

easy method to assess a used filter's remaining capacity, and it is

even harder when the machine's history is not known. However,

in all safety it can be said that if dust particles can be discerned on

top of the filter (clean side) it is spent.

3. Paper filter

The paper filter should not be cleaned, but is replaced with a new

one. The replacement frequency depends very much on the care of

the foam plastic filter.

Exercise extreme care when the filter is dismantled so that

dust particles do not fall down in the carburettor inlet. Vacuum

cleaning is the best method to remove spillage and to clean the

filter compartment.

A useful rule for filter replacement is: Replace the paper filter

when the yellow paper colour is no longer visible.