IGNITION SYSTEM

6

12

Function

The ignition system is fully enclosed and has no moving

parts. It is insensitive to moisture and dirt. The design is

such that the ignition point does not need to readjustment.

Husqvarna K960 has integrated overspeed protection in the

electronic unit that limits the engine's speed to 9,300 rpm.

The ignition system consists of the primary coil (A) and

secondary coil (B) which are both surround ed by the iron

core (C). An electronic digital unit (D) manages the switch

function.

Current is generated in the primary coil when the fly -

wheel's permanent magnet passes the coil and has the voltage

sequence illustrated in the diagram. (The dashed line indi -

cates the voltage that should be generated if the current is

not broken.)

The ignition point is determined by the electronic unit,

which sense the voltage variation in the primary coil and

breaks the current at the right level, at the same time the

engine piston is just below the upper turning point. At the

breaking instant the voltage in the primary coil rises from

5 V (volt) to approximately 200 V through induction. At the

same time a high voltage, approximately 20,000 volt, is

transformed in the secondary coil to the spark plug.

Electronic

circuit

breaker

STOP

control

Volts

+

-

0

Ignition

point

S

N

S

N

1

1

A

D

B

C

2

2

3

3

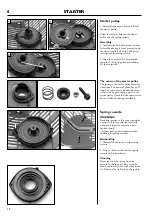

Ignition module

Individual components can not

be replaced.

The ignition lead, contact

unit to the spark plug and seals

on the ignition module can be

replaced.

The short-circuit contact

(arrow) is connected to the stop

switch.

Ignition module

The ignition module's components are

fully enclosed to withstand external

manipulation. Individual components

can not be replaced.

The ignition lead, contact unit to the

spark plug and seals on the ignition

module can be replaced.

The ignition module requires no perio-

dic servicing. (Nevertheless, the distance

to the flywheel's magnet may need

adjusting.)

The ignition module has two connec-

tions. One to the spark plug and the

other is the short-circuit contact (arrow)

to the stop switch.

Spark plug

The spark plug's electrode gap should be

.02 in./0.5 mm.

The electrodes should be free of soot

deposits and oil. Brush clean with a wire

brush.

A convex centre electrode and a worn

side electrode impair the ignition charac-

teristics. Replace the spark plug.

Spark plug

The spark plug's electrode gap

should be .02 in./0.5 mm.

0.5 mm

.02 in.