11

CARBURETOR

If the carburetor needs readjustment, open the carburetor

MAIN JET ADJUSTMENT needle valve approximately 2

full turns from its seat. After the engine is started and

warmed up, adjust the needle valve for best operation under

full load, if possible. In cold weather, starting may be

facilitated by opening the needle valve slightly more, then

readjusting to normal running position after engine is

started.

Figure 15

The correct amount of throttle plate opening for the proper

low idle speed is obtained by means of the THROTTLE

STOP SCREW. However, this is set at the factory so that no

further adjustment is necessary. The IDLE ADJUSTMENT

is for smooth low speed operation and this adjustment, if

necessary, must be made with the carburetor throttle lever

closed. Initial setting is approximately 1-1 /2 turns.

TIMING

No timing adjustment or breaker point setting is necessary.

All solid state components are neatly molded into the

stator which is mounted to the flywheel end bearing plate.

The only mechanically moving part is the magnetic rotor, a

component part of the flywheel.

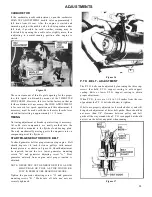

STARTER-GENERATOR DRIVE BELT

To check generator belt for proper tension stop engine. Belt

should depress 1/4 inch between pulleys with normal

thumb pressure as shown in Figure 16. Should adjustment

be required, loosen the two lower generator mounting

screws "B" and generator adjusting screw "A." Pivot

generator outward from engine until proper tension is

obtained.

NOTE: NEVER PRY OUT GENERATOR WITH A LONG

HEAVY BAR OR TOOL AS THIS WOULD RE-

SULT IN PREMATURE BEARING FAILURE.

Tighten the generator adjusting screw "A" and generator

mounting screws "B ." Make sure

all bolts and nuts

are

securely tightened.

Figure 16

P.T.O. BELT - ADJUSTMENT

The P.T.O. belts can be adjusted by loosening the three cap-

screws that hold P.T.O. support casting to axle support

casting. Raise or lower P.T.O. support casting to obtain

proper adjustment.

When P.T.O. levers are 1-1/8 to 1·1/4 inches from the rear

of quadrant the P.T.O. belt should start to tighten.

If belts are properly adjusted (as described above) and still

drag, check adjustment of lower belt guide. There should be

not more than 1/8" clearance between pulley and belt

guide all the way around when P.T.O. is engaged but should

not rest on the belt at any point when running.

Figure 17

ADJUSTMENTS

Содержание 1254-06

Страница 1: ......

Страница 19: ...18 ...

Страница 22: ...LUBRICATION AND MAINTENANCE RECORD DATE PERFORMED DESCRIPTION OF MAINTENANCE HRS RUN ...

Страница 23: ......

Страница 24: ......