212

Series Tooling Alcoa Fastening Systems

17

D

ISASSEMBLY

See applicable illustrations.

For parts identification, refer to applicable fig-

ures, tables and parts lists. Numbers in paren-

theses ( ) are reference numbers shown in man-

ual.

The following procedure is for complete disas-

sembly of tool. Disassemble

ONLY

those compo-

nents necessary to replace damaged or worn O-

rings, QUAD rings, back-up rings and other com-

ponents.

1. Disconnect tool from air source.

2. Unscrew Retaining Nut (2) and remove Nose

Assembly. Remove Pintail Tube (1).

3. Unscrew Bleed Plug (4) including O-ring (5)

from top of Handle/Head (3). Turn tool over

and allow fluid to drain into container - - tool

may be cycled to clear tool more completely.

Discard fluid.

4. Pull Deflector (17) off End Cap (14).

5. Using wrench, unscrew End Cap (14). Slide

out Spring (13)

6.

CAUTION - - to prevent damage to Piston

Seals and Gland Seals when removing

them - - install

OPTIONAL

POLY-SEAL

Insertion Tool (121694-212).

Thread POLY-SEAL Insertion Tool, 121694-

212, into head/handle.

7. Slide Spacer, 123112-2, over piston rod.

8. Thread Piston Assembly Tool, 123111-2, onto

piston.

9. Push complete piston from front using brass

drift - -allow clearance for

piston as it exits tool.

10.Remove Piston Assembly Tool, Spacer, and

POLY-SEAL Insertion Tool.

11.Inspect Piston (6) for wear, scoring or dam-

age. Replace when necessary. Remove

Retaining Ring (64) and Washer (63). Hold

tool securely with bottom up.

12. Remove three Button Head Screws (51) with

1/8 hex key. Remove Muffler End Cap (50)

and Bottom Exhaust Gasket (48). Remove

Muffler (47) with O-ring (46) from end cap.

13. Remove Retaining Ring (45) from Cylinder

(24).

14. Screw Button Head Screws (51) back into

Cylinder Head (43). Carefully pull on

screws to remove Cylinder Head (43).

!

!

WARNING

Be sure air hose is disconnected before

cleaning or when replacing worn or

damaged tool components. Tool may

be actuated if not disconnected and

cylinder is under pressure. Severe

personal injury may result.

WARNING

Never cycle tool without bleed plug

installed and tightened, the bottle

installed and tightened in tool head, or

the fillport held over a suitable con-

tainer.

If fluid is present it will spray

out of tool. Severe eye injury may

result.

Air pressure MUST be set at 20

- 40 psi.

Содержание ALCOA 212

Страница 1: ...11 09 2009 HK838 INSTRUCTION MANUAL 212 PNEUDRAULIC INSTALLATION TOOL...

Страница 2: ......

Страница 4: ...This page is intentionally blank...

Страница 8: ...212 Series Tooling Alcoa Fastening Systems 6 Fig 1 Outline Drawing...

Страница 23: ...212 Series Tooling Alcoa Fastening Systems 21 Fig 5 Handle Assembly...

Страница 25: ...212 Series Tooling Alcoa Fastening Systems 23 Fig 10 Piston and Gland Removal...

Страница 26: ...212 Series Tooling Alcoa Fastening Systems 24 Fig 11 Piston and Gland Insertion assembly...

Страница 27: ...212 Series Tooling Alcoa Fastening Systems 25 Fig 12 Gland Assembly...

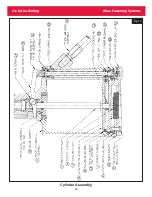

Страница 28: ...212 Series Tooling Alcoa Fastening Systems 26 Fig 13 Cylinder Assembly...