12

6

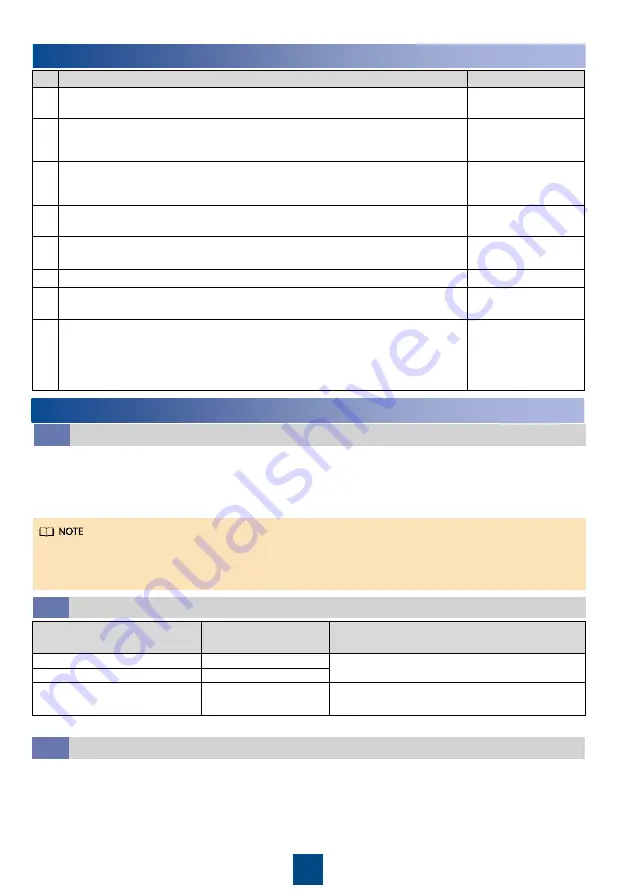

Verifying the Installation

No. Check Item

Check Result

1

All water pipes are properly and securely installed, and free from leakage,

blockage, and sharp turns.

□

Passed

□

Failed

2

The liquid level detector is level. The water pan is free from foreign

matter such as cable remains and thermal insulation foam. Cables are

securely bound and not in the water pan.

□

Passed

□

Failed

3

The distance between two chilled water pipes outside the cabinet is

sufficient (recommended distance: longer than 25 mm), the hose is

tightly wrapped with insulation foam, and joints are secured using glue.

□

Passed

□

Failed

4

The pipeline system has passed the pressure preservation and air

tightness tests.

□

Passed

□

Failed

5

The needle valve plugs are secured (torque of 0.45

±

0.05 N•m), and

screw caps are tightened.

□

Passed

□

Failed

6

The cabinet is reliably grounded.

□

Passed

□

Failed

7

The power cables and signal cables are correctly connected and properly

separated. Strong-current and weak-current cables are separately bound.

□

Passed

□

Failed

8

The chilled water valve and its actuator are securely installed. The chilled

water connector joints have been wrapped with thermal insulation foam,

and no metal or hose is exposed. Cables are securely connected to the

chilled water valve actuator. The actuator manual button is reset (ejected

state).

□

Passed

□

Failed

7

System Power-On

1. Turn on the smart cooling product switch in the power distribution cabinet and the AC1 and AC2

switches on the smart cooling product.

2. After the device is powered on for the first time, the LCD displays the

Quick Settings

screen. Log

in as the admin user, and set parameters as instructed, such as language, date format, date, time,

and time zone. If the device is not powered on for the first time, the home screen is displayed.

•

Users are classified into

admin

and

operator

. The preset password is

000001

for both types of

users.

•

After powering on, the smart cooling product is in shutdown mode.

Power-On

7.1

If a T/H sensor outside the cabinet is installed, enable it. Path:

Settings

>

System Settings

>

Common Settings

or

Settings

>

System Settings

>

T/H Sensor

(Optional) Enabling the T/H Sensor Outside the Cabinet

7.3

(Optional) Setting the T/H Control Type

7.2

Application Scenario

Recommended T/H

Control Type

Remarks

Cold aisle containment

Cold aisle control

If cold aisle T/H sensors are not configured,

you can also choose the supply air control.

Hot aisle containment

Cold aisle control

Non-aisle containment

Return air control

If cold aisle T/H sensors are configured,

you can also choose the cold aisle control.

Path:

Settings

>

System Settings

>

Common Settings

or

Settings

>

System Settings

>

T/H Sensor.