GENERAL INFORMATION

1-20

b. If the adjustment is correct, the 0 mark on the thimble will align exactly with the 0 mark on the

sleeve line. If the marks do not align, the micrometer is out of adjustment.

c. Follow the manufacturer’s instructions to adjust the micrometer.

2B. To check a micrometer larger than 1 in. or 25 mm use the standard gauge supplied by the

manufacturer. A standard gauge is a steel block, disc or rod that is machined to an exact size.

a. Place the standard gauge between the spindle and anvil, and measure its outside diameter or

length. If the micrometer has a ratchet stop, use it to ensure that the proper amount of pressure is

applied.

b. If the adjustment is correct, the 0 mark on the thimble will align exactly with the 0 mark on the

sleeve line. If the marks do not align, the micrometer is out of adjustment.

c. Follow the manufacturer’s instructions to adjust the micrometer.

Care

Micrometers are precision instruments. They must be used and maintained with great care. Note

the following:

1. Store micrometers in protective cases or separate padded drawers in a tool box.

2. When in storage, make sure the spindle and anvil faces do not contact each other or another object.

If they do, temperature changes and corrosion may damage the contact faces.

3. Do not clean a micrometer with compressed air. Dirt forced into the tool will cause wear.

4. Lubricate micrometers with WD-40 to prevent corrosion.

Metric micrometer

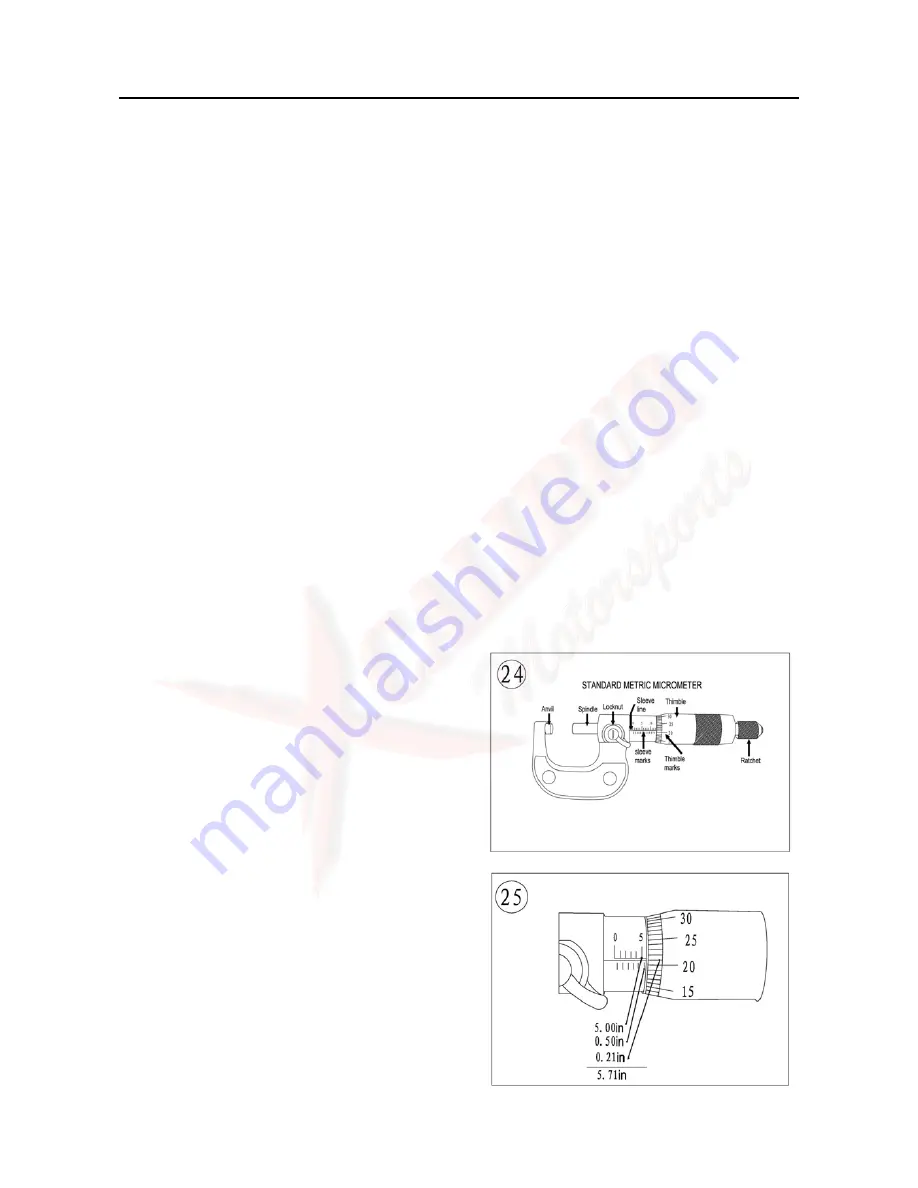

The standard metric micrometer (

Figure 24

)

is

accurate to one one-hundredth of a millimeter (0.01

mm). The sleeve line is graduated in millimeter and

half millimeter increments. The marks on the upper

half of the sleeve line equal 1.00 mm. Each fifth mark

above the sleeve line is identified with a number. The

number sequence depends on the size of the

micrometer. A 0-25 mm micrometer, for example, will

have sleeve marks numbered 0 through 25 in 5 mm

increments. This numbering sequence continues with

larger micrometers. On all metric micrometers, each

mark on the lower half of the sleeve equals 0.50 mm.

The tapered end of the thimble has 50 lines

marked around it. Each mark equals 0.01 mm. One

completer turn of the thimble aligns its 0 mark with the

first line lower half of the sleeve line or 0.50mm.

When reading a metric micrometer, add the

number of millimeters and half-millimeters on the

sleeve line to the number of one one-hundredth

millimeters on the thimble. Perform the following steps

while referring to

Figure 25

.

Содержание UTV 700 2009

Страница 1: ...HUANSONG UTV 700 SERVICE MANUAL 2009 ...

Страница 96: ...GENERAL SPECIFICATIONS 2 23 HYDROGRAPHIC CHART Hydrographic chart Pressure splash ...

Страница 97: ...GENERAL SPECIFICATIONS 2 24 LUBRICATION OIL WAY ...

Страница 111: ...3 14 Oil gallery bolt 7 Nm 0 7 m kg 5 1 ft lb 12 Install console passenger seat driver seat Refer to SEATS in chapter 5 ...

Страница 146: ...CYLINDER HEAD 4 5 No Name part Qty Remarks 13 Thermo switch 1 1 For installation reverse the removal procedure ...

Страница 205: ...MIDDLE GEAR 4 64 Order Job Part Qty Remarks 11 Middle driven shaft 1 For installation reverse the removal procedure ...

Страница 246: ...5 31 BRAKE SYSTEM No Part Name Qty Remarks 26 Caliper piston seal 1 27 Bleed screw 1 ...

Страница 323: ...ELECTRIC STARTING SYSTEM 6 11 ELECTRIC STARTING SYSTEM CIRCUIT DIAGRAM Switch C D I Relay Motor Battery ...

Страница 330: ...CHARGING SYSTEM 6 18 CHARGING SYSTEM CIRCUIT DIAGRAM Ignition coil C D I Magneto Rectifier ...

Страница 333: ...LIGHTING SYSTEM 6 21 LIGHTING SYSTEM CIRCUIT DIAGRAM Flash Relay switch Rectifier Battery Light ...

Страница 337: ...SIGNALING SYSTEM 6 25 SIGNALING SYSTEM CIRCUIT DIAGRAM Flash Relay switch Rectifier Battery Light ...

Страница 348: ...COOLING SYSTEM 6 36 COOLING SYSTEM CIRCUIT DIAGRAM Temperature control switch fan motor Battery Circuit breaker switch ...

Страница 352: ...2WD 4WD SELECTING SYSTEM 6 40 2WD 4WD SELECTING SYSTEM CIRCUIT DIAGRAM Transfer Switch Relay Battery Motor Indicator ...