– 20 –

Form 2 Common Malfunctions

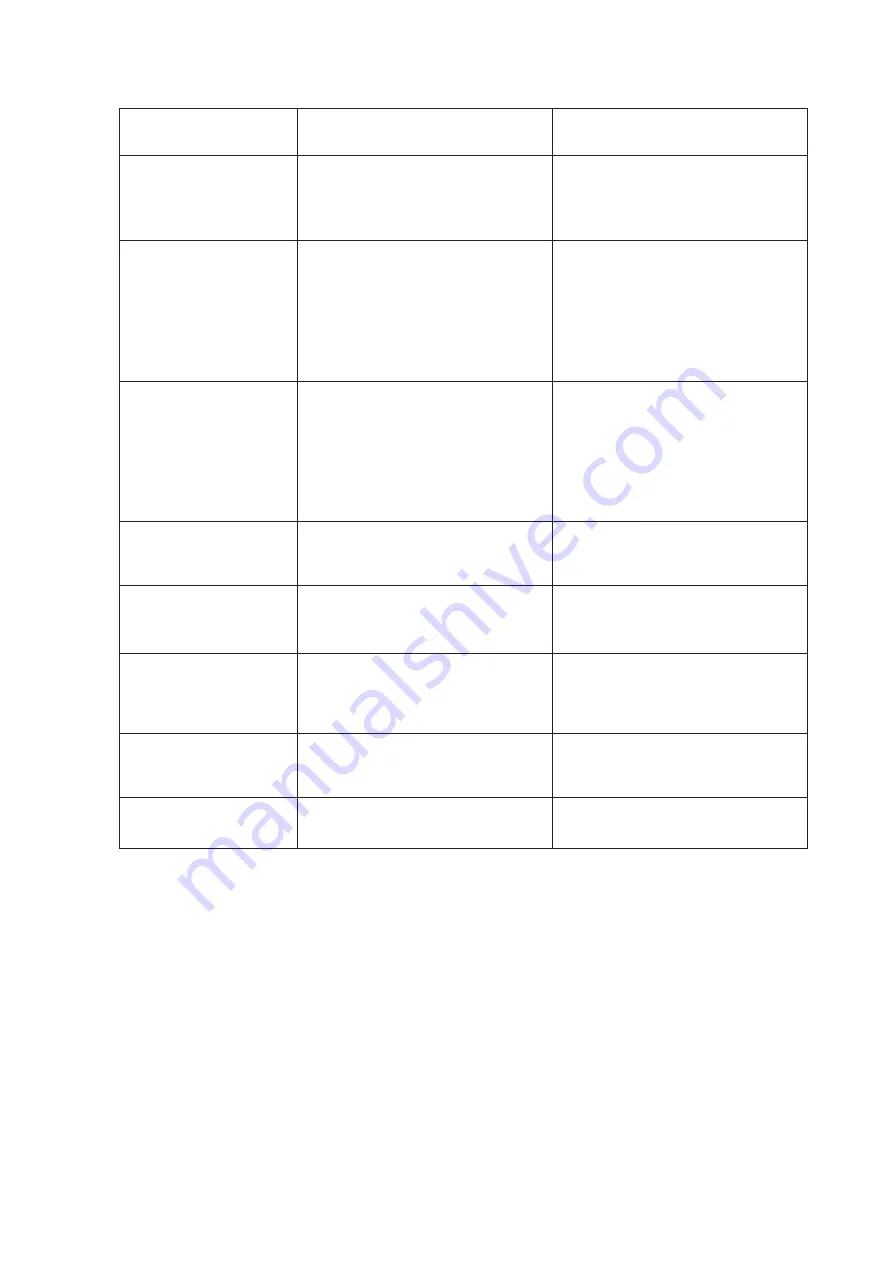

Malfunction

Description

Reason

Solution

The machine does not

work.

1. Power failure

2. Power cord is loose.

3. Control power fuse is broken.

1. Turn off the power switch and

check the power.

2. Find out the problem and fix it.

3. Replace the fuse.

The machine has low

Heating capacity

1. Refrigerant is insufficient.

2. Water pipe’s thermal insulation

performance is poor.

3. Dry filter is clogging.

4. The heat exchanger with air has

poor cooling.

1. Check if there is leakage and

note the standard quantity of

refrigerant.

2. Strengthen water system

insulation function.

3. Replace the dry filter.

4. Clean heat exchanger with air.

The compressor does

not work

1. Power supply or the controller is

broken.

2. The compressor’s contactor fails.

3. The wire is loose

4. The compressor’s overheating

protection works.

1. Find out the reason and solve it

accordingly.

2. Replace the contractor.

3. Find out the loose point and fix it.

4. Identify the reason of

overheating and then turn on the

machine after trouble shooting.

The compressor works

noisily

1. Internal components are

damaged.

2. Frozen oil is not enough.

1. Replace the compressor.

2. Add enough frozen oil.

The fan does not work

1. The capacitor is broken.

2. The screw is loose.

3. The motor is broken.

1. Replace the capacitor.

2. Tighten the screw.

3. Replace the motor.

The machine does not

produce heat, while the

compressor is working.

1. Refrigerant spreads out totally.

2. The compressor is broken.

1. Check if there is leakage and

fulfill the standard quantity of

refrigerant.

2. Replace the compressor.

Exhaust flue pressure is

too high.

1. Refrigerant is too much.

2.Fluorine-way system contains

non-condensable gas.

1. Expel excessive refrigerant.

2. Exclude non-condensable gas.

Suction pressure is too

low.

1. Dry filter is blocked.

2. Refrigerant is too little.

1. Replace the dry filter.

2. Check if there is leakage and fix it.

Содержание HTW-AT-O-200VA1

Страница 23: ...23...