lp-666 Rev. 003 Rel. 001 Date 2.25.20

73

g.

i. For 400 - 500 Models: Loosen the band clamp from the air intake

assembly. Then pull the entire combustion assembly towards you,

while removing or pushing aside any wiring to allow removal of

the assembly. Set aside in a safe location for eventual reinstallation.

ii. For 650 - 1000 Models: Pull the entire combustion assembly

towards you and then down to disconnect from the air intake

assembly. Then remove or push aside any wiring to allow

removal of the assembly. Set aside in a safe location for eventual

reinstallation.

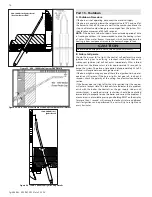

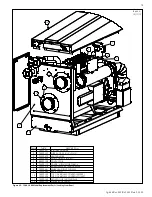

iii. For 1500 - 2000 Models: First, remove the five (5) screws

attaching the cabinet post to the left side of the boiler cabinet

assembly. Then remove the post.

Then remove the three (3) screws attaching the air intake assembly.

The heat exchanger features a hinged sliding device to ease

service. First remove the pin located to the left of the door. This

locks the hinge in place. After the pin is removed the door will

swing at the hinge, providing better access to the inside of the

heat exchanger. BE CAREFUL NOT TO DAMAGE THE COMBUSTION

ASSEMBLY, WHICH IS MOUNTED TO THE DOOR, WHEN OPENING

AT THE HINGE.

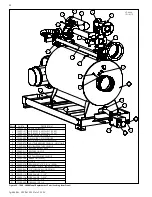

After the pin is removed: (1) Lift the air intake pipe. (2) Spin air

intake pipe while sliding the combustion assembly out. (3) Swing

the assembly open to allow access to the combustion chamber.

(4) Slide the assembly back toward the heat exchanger and use

the removed pin to secure in the open position while performing

maintenance. See Figure 57.

WARNING

!

Do not use solvents to clean any of the burner components. The

components could be damaged, resulting in unreliable or unsafe

boiler operation, substantial property damage, severe personal

injury, or death.

4

2

1

6

3

5

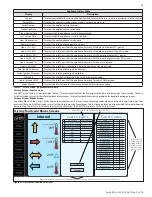

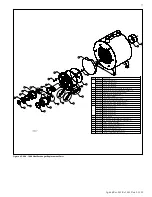

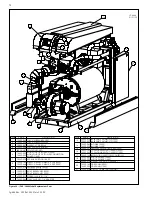

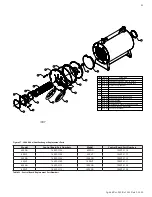

Figure 56 - 400 - 1000 Model Heat Exchanger Detail - Burner Door Torque

Sequence

1

2

3

Figure 57 - 1500 - 2000 Model Heat Exchanger Detail - Sliding Out the Combustion Assembly

2. Spray the coils liberally with the FDA approved liquid lime scale

remover. Confine the spray to the area being cleaned. Avoid getting

the ceramic target wall wet. If the condensate system is blocked, use

a vacuum to clear it.

3. Scrub coils of any buildup

with a nylon, stainless steel, or

brass brush. Do not use a steel

brush. Vacuum the debris from

the coils.

4. Spray the coils again with

clear tap water. Confine

the spray to the area being

cleaned. Flush the combustion

chamber with fresh water

until it runs clear from the

condensate reservoir. At this

point, the boiler should be

ready to be reassembled.

a. Inspect gaskets.

b. Reinstall the combustion

assembly.

c. Reinstall and tighten the

bolts to the burner plate

using staggered tightening

sequence. See Figure 56.

d. Reconnect all wiring

connections.

e. Use pipe dope or tape to

reconnect the flex line to

the gas valve. (IMPORTANT: CHECK FOR GAS LEAKS!)

f. Reinstall the air intake.

g. Restore gas and power to the boiler.

h. Turn boiler power on and create a heat demand. When boiler is

lit observe condensate flow from the boiler. Be sure the boiler is

operating properly.

i. Reinstall the condensate trap cleanout trap.