LP-719 Rev. 000 Rel. 000 Date 6.25.20

24

NOTE:

In piping applications utilizing a single zone, it is recommended that the installer use flow / check valves with weighted seats at or near

the appliance to prevent gravity circulation.

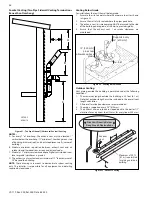

Figure 15 - Boiler without Central Heating Circulator

NOTICE

Figure illustrates the basic plumbing requirements for a 150 / 199 boiler installation without an external Central Heating circulator; the

boiler’s internal circulator delivers flow to the heating system. Application is limited to zone valve (or non-circulator) distribution systems

with small flow requirements (e.g. systems requiring no more than 9 gpm at 9 ft. of head pressure).

NOTES:

1. This drawing is meant to show system piping concept only. Installer is responsible for all equipment and detailing required by local codes.

2. The minimum pipe size of DHW piping should be ¾” diameter and CH piping should be 1” in diameter.

3. Circulators are shown with isolation flanges. The alternative is standard flanges with full port ball valves. Purge valves can be used with circulator

flanges as an alternative.

4. Install a minimum of 12 diameters of straight pipe upstream of all circulators.

5.

VERY IMPORTANT

– Minimum flow rates outlined in this manual (2 gpm) must be maintained through the heat exchanger to minimize short

cycling.

6. In a valve-based system, each heating zone has a zone valve which opens when that zone calls for heat. Each zone thermostat is wired to its

corresponding zone valve. Contacts in the zone valves provide a signal to the boiler to operate when there is a call for heat.

7.

Unit is equipped with built-in primary pump for the heating loop.

This pump is sized to ensure proper flow rate through the boiler heat

exchanger and related piping.

8. IWH Applications - a mixing valve is recommended if the DHW temperature is set above 119

o

F.

9. For direct (not primary / secondary) piping applications, it is required to install the expansion vessel on the return side of the boiler as illustrated.

WARNING

!

The piping will not support the weight of the circulators. Refer to the circulator manufacturer’s instructions to properly support the circulator.

Failure to comply with these instructions could result in property damage, severe personal injury, or death.

Cap this fitting

when not in use

For direct (not primary / secondary) piping applications, the expansion vessel must be

placed on the return side of the boiler as illustrated. Placement of flow resticting de-

vices, such as check valves, is prohibited between the boiler return and the expansion

vessel. Failure to place the expansion vessel as instructed, may result in the release of

the pressure relief valve, property damage, severe personal injury, or death.

WARNING

!

150 / 199 Boiler Model Heating Only Installation

If the boiler is to be used only in Heating Mode (not connected to an indirect water heater), cap the fitting as indicated in the figure

above. A cap is included with the boiler. The electrical connection of the 3-way valve motor MUST BE DISCONNECTED while the

boiler is operating in central heating mode. This will lock the valve motor in central heating mode and ensure freeze protection

operates properly. Failure to disconnect the valve may disable boiler freeze protection and result in property damage.

CAUTION