Warnings

The following general safety

precautions must be observed during

all phases of operation, service, and

repair of this product. Failure to

comply with these precautions or

with specific warnings elsewhere in

this manual violates safety

standards of design, manufacture,

and intended use of the product.

Hewlett-Packard Australia Limited

assumes no liability for the

customer’s failure to comply with

these requirements.

Ground the equipment

For safety

Class 1 equipment (equipment having a

protective ground terminal), an

uninterruptible safety ground must be

provided from the mains power source to

the product input wiring terminals or

supplied power cable.

DO NOT operate the product in an

explosive atmosphere or in the

presence of flammable gases or

fumes.

For continued protection against

fire, replace the line fuse(s) only with

fuse(s) of the same voltage and current

rating and type. DO NOT use repaired fuses

or short-circuited fuse holders.

Keep away from live circuits

Operating personnel must not remove

equipment covers or shields. Procedures

involving the removal of covers and shields

are for use by service-trained personnel

only. Under certain conditions, dangerous

voltages may exist even with the

equipment switched off. To avoid electrical

shock, DO NOT perform procedures

involving cover or shield removal unless you

are qualified to do so.

DO NOT operate damaged

equipment

Whenever it is possible that

the safety protection features built into this

product have been impaired, either through

physical damage, excessive moisture, or

any other reason, REMOVE POWER and do

not use the product until safe operation can

be verified by service-trained personnel. If

necessary, return the product to a Hewlett-

Packard Sales and Service Office for service

and repair to ensure the safety features are

maintained.

DO NOT substitute parts or modify

equipment

Because of the danger of

introducing additional hazards, do not

install substitute parts or perform any

unauthorized modification to the product.

Return the product to a Hewlett-Packard

Sales and Service Office for service and

repair to ensure features are maintained.

DO NOT clean with fluids

Doing so may make the equipment unsafe

for use.

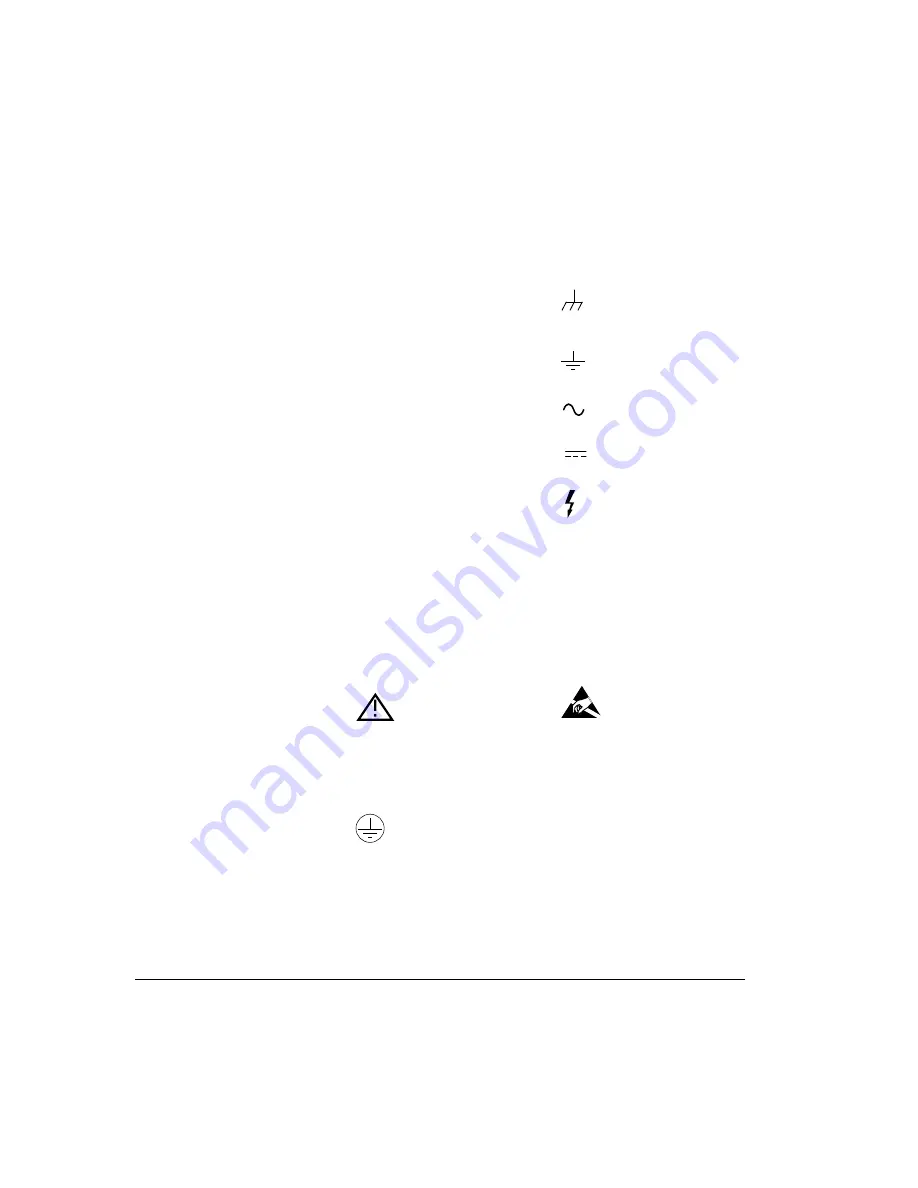

Safety Symbols

Instruction manual symbol affixed to

product. Indicates that the user must refer

to the manual for specific Warning or

Caution information to avoid personal

injury, or damage to the product.

Protective conductor terminal indicates the

field wiring terminal that must be

connected to ground before operating the

equipment—protects against electrical

shock in case of fault.

Frame or chassis ground terminal—typically

connects to the equipment’s metal frame.

Earth (ground) terminal.

Alternating current (ac).

Direct current (dc).

Indicates hazardous voltages.

WA R N I N G

Calls attention to a procedure, practice, or

condition that could cause bodily injury or

death.

CAU T I O N

Calls attention to a procedure, practice, or

condition that could possibly cause damage

to equipment or permanent loss of data.

Indicates that antistatic precautions should

be taken.