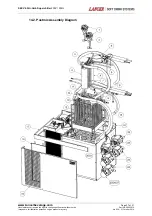

S8E V2.5 Hi-Carb Superchiller

230V / 50Hz

www.lancerbeverage.com

Page 12 of 31

Hoshizaki Lancer reserve the right to change specifications without notice.

Part No: 68000016

Images are for illustration purposes only as product may vary.

No 038 – 21 October 2014

Warning

To avoid possible fatal electric shock or serious injury the

Superchiller must be electrically grounded.

Electrical Connection Must Be Made In Accordance With The

Appropriate Local Codes And Regulations.

Use of an RCD is recommended.

6.10

Plumbing the drain and CO

2

exhaust

The 19mm overflow drain tube exiting from the base of the tank should be plumbed to a suitable

drain, installation in accordance with AS/NZS 3500.1 and AS/NZS 3500.2.

The 6mm barb labelled as CO2 EXHAUST should be plumbed to an outside safe area.

6.11

Commissioning

Unplug carbonator and recirculation pumps power supply leads from electrical box located

under lid.

Connect Superchiller power supply lead to an appropriate 3 pin socket outlet and switch on.

Compressors, condenser fans and agitator motors should all operate.

When Superchiller ice bank is fully formed (approx. 4 hours) the compressors and condenser

fans will cycle off, but agitator will run continuously (unit has cycled off).

After Superchiller has cycled off, reconnect carbonator and recirculation pumps.

6.12

Purge System

Progressively activate each dispensing valve or Bargun connected to the Superchiller systems until

an uninterrupted flow of soda, water (where applicable), and syrup pours from each dispenser.

6.13 Sanitise System

Prepare sanitising solution:

Prepare sanitising solution in accordance with the manufacturer’s written recommendations and

safety guidelines.

Sanitising BIB System

Remove all disconnects from BIB containers.

Immerse all disconnects in warm water and clean using a nylon bristle brush. Rinse with clean

water.

Prepare sanitising solution according to manufacturer’s instructions.

Attach sanitising fittings to BIB disconnects, if sanitising fittings are not available cut fittings from

empty BIB bags.

Immerse all sanitising fittings with attached BIB disconnects in bucket of sanitising solution.

Operate all dispensing valves until the sanitising solution flows from the valve. Allow sanitiser

to remain in lines for fifteen (15) minutes.

Immerse all sanitising fittings with attached BIB disconnects in bucket of clean water. Operate

all dispensing valves until all sanitiser has been flushed from the system.