SPYDER® LON PROGRAMMABLE, VAV/UNITARY CONTROLLERS

63-2685—03

22

Table 8. Status LED states.

Step 3. Checkout Completion

At this point the controller is installed and powered. To

complete the checkout, the N

IAGARA

F

RAMEWORK

® application

(run on a PC) is used to configure the I/O and functions of the

controller. Refer to the Programming Tool User Guide, form no.

63-2662, for controller configuration and programming details.

CONTROLLER REPLACEMENT

There are no serviceable or repairable parts inside the

controller.

WARNING

Fire, Explosion, or Electrical Shock Hazard.

Can cause severe injury, death or property damage.

Do not attempt to modify the physical or electrical

characteristics of this device in any way. Replace the

controller if troubleshooting indicates a malfunction.

WARNING

Electrical Shock Hazard.

Can cause severe injury, death or property damage.

Disconnect power supply before beginning controller

replacement to prevent electrical shock or equipment

damage.

Terminal Block Removal

To simplify controller replacement, all terminal blocks are

designed to be removed with the wiring connections intact and

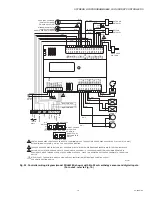

then re-installed on the new controller. See Fig. 26 and refer to

the following procedure:

IMPORTANT

To prevent bending or breaking the alignment pins on

longer terminal blocks, insert the screwdriver at

several points to evenly and gradually lift up the

terminal block.

Insert the screwdriver blade no more than 1/8 in.

(3 mm) to prevent damage to the terminal block align-

ment pins on the controller circuit board.

Fig. 26. Removing Terminal Blocks.

1.

Use a thin-bladed screwdriver to evenly raise the

terminal block from its alignment pins:

a. For short terminal blocks (1 to 5 terminals), insert

screwdriver blade in the center of the terminal block

and use a back and forth twisting motion to gently

raise the terminal block from its alignment pins 1/4 in.

(6.35 mm).

b. For long terminal blocks (6 or more terminals), insert

screwdriver blade on one side of the terminal block

and gently rotate the blade 1/4 turn. Then, move to

the other side of the terminal block and do the same.

Repeat until the terminal block is evenly raised 1/4

in. (6.35 mm) from its alignment pins.

2.

Once the terminal block is raised 1/4 in. (6.35 mm) from

its alignment pins, grasp the terminal block at its center

(for long terminal blocks grasp it at each end) and pull it

straight up.

Controller Replacement (PVL0000AS,

PVL4022AS, and PVL6436AS)

For PVL0000AS, PVL4022AS, and PVL6436AS controllers,

which are hard-wired to an actuator, perform the following

actions to replace the complete assembly (controller and

actuator):

1.

Remove all power from the controller.

2.

Remove the two air flow pickup connections from the

pressure sensor.

3.

Remove the terminal blocks (See “Terminal Block

4.

Remove the old controller and actuator assembly from

its mounting.

• Loosen the two bolts on the actuator clamp to release

the actuator from the shaft.

• Remove the controller’s mounting screws.

• Gently pull the controller and actuator assembly

straight out, until the assembly is clear of the actuator

shaft.

5.

Mount the new controller and actuator assembly (See

LED State

Blink Rate

Status or Condition

OFF

Not applicable

No power to processor,

LED damaged, low

voltage to board, or

controller damaged.

ON

ON steady;

not blinking

Processor and/or

controller is not operating.

Very Slow Blink

(continuous)

1 second ON,

1 second OFF

Controller is operating

normally.

Slow Blink

(continuous)

0.5 second ON,

0.5 second OFF

Controller alarm is active,

controller in process of

download, or controller

lost its configuration.

Medium Blink

(continuous)

0.25 second ON,

0.25 second OFF

Controller firmware is

loading.

Fast Blink

(continuous)

0.10 second ON,

0.10 second OFF

Controller is in manual

mode under control of the

PC-based software tool.

SHORT TERMINAL BLOCK

LONGTERMINAL BLOCK

M23563