S8700B,D-F,J-M DIRECT SPARK IGNITION CONTROLS

7

69-1299

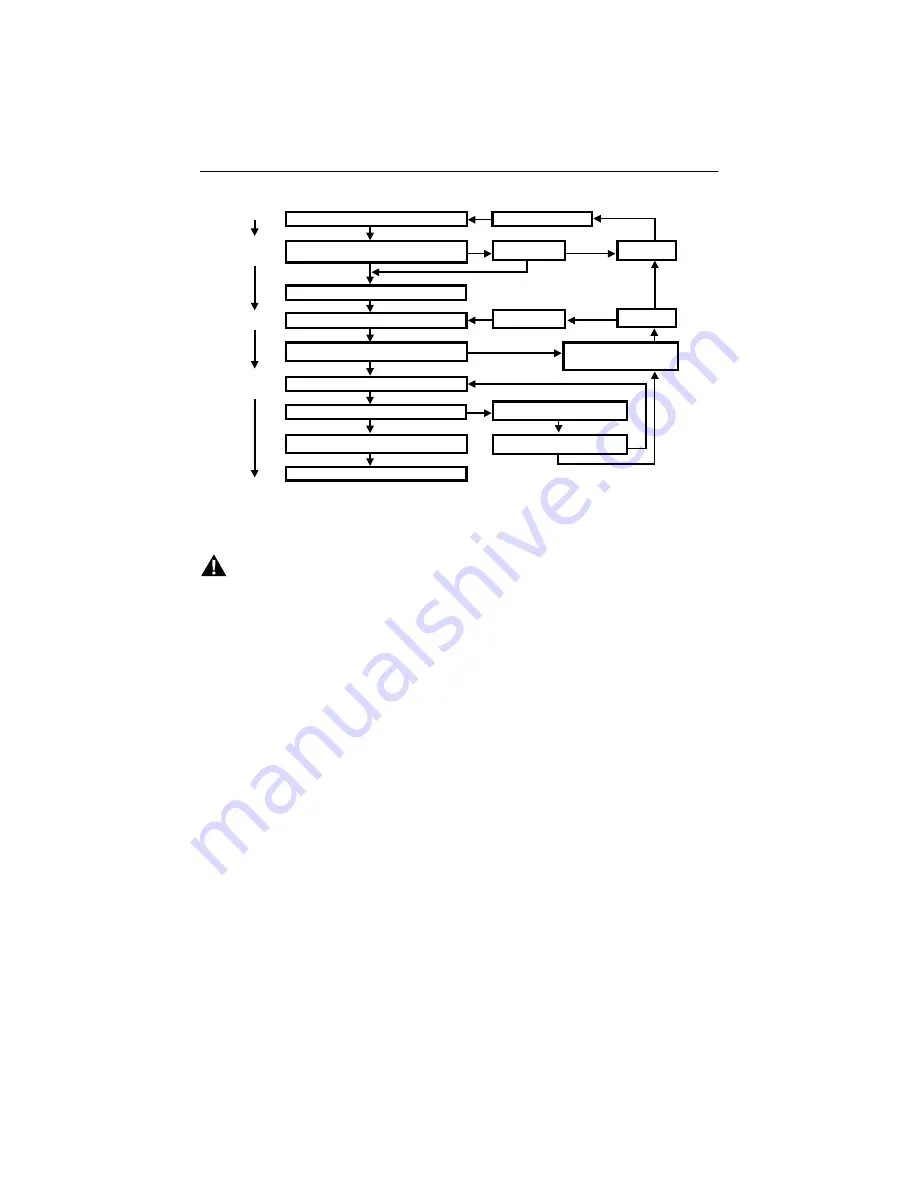

Fig. 5. S8700E,F,L,M retry sequence of operation.

WARNING

High Voltage Hazard.

Shock can cause personal injury.

To prevent electric shock, do not allow fingers to

touch the stripped end of the jumper or the

spark terminal.

4.

Perform this test immediately upon energizing the

system, before the S8700 goes into lockout and

interrupts the spark circuit. Touch one end of the

jumper firmly to the S8700 GND terminal. Do not

remove the existing ground lead. Slowly move the

other end of the jumper wire toward the spark ter-

minal on the control to establish a spark. Pull the

wire away from the spark terminal and note the

length of the gap at which the spark discontinues.

5.

A spark length of 1/8 in. (3 mm) or more indicates

satisfactory voltage output. If no arc can be

established or the maximum spark is less than 1/8

in. (3 mm) and power to the S8700 input terminals

was proved, replace the S8700.

Ignition Cable

Check the electrical continuity of the ignition cable and

make certain that the cable is not in contact with metal

surfaces. The total cable length should not exceed 6 ft

(1.8m). Check connection to the spark terminal on the

S8700 and the boot connection to the igniter/sensor.

Make certain they are clean and tight.

Grounding Connections

A common ground is required for the main burner, spark

igniter mounting bracket or igniter sensor mounting

bracket, and the GND (burner) terminal of the S8700. If

the common ground connections are poor or erratic,

safety shutdown can occur occasionally even though

operation is normal at time of checkout. Therefore, if

nuisance shutdowns have been reported, be sure to

check ground connections.

Electrical ground connections at the spark igniter or

igniter sensor and the S8700 must be clean and tight. If

leadwire is damaged or deteriorated, use only a No. 14

or No. 18 gauge, moisture resistant, thermoplastic

insulated wire with 221

°

F (105

°

C) minimum rating as a

replacement.

Flame Sensor Circuit

The S8700 provides ac voltage to the flame sensor.

When a flame of sufficient size is present, the ac

voltage is rectified and sensed as a dc flame current by

the S8700. The S8700 will operate with a steady 1.0 µA

dc flame current. However, reliable appliance operation

requires at least 2.0 µA flame current (measured with

an analog dc microammeter during worst case appli-

ance checkout.).

CALL FOR HEAT (24 VAC INPUT TO 24 VAC TERMINAL).

SAFE START CHECK. FLAME DETECTED?

(LED BLINKS RAPIDLY).

PREPURGE (L AND M MODELS).

SPARK GENERATOR POWERED; MAIN VALVE OPENS.

MAIN BURNER LIGHTS AND FLAME SENSED

DURING TRIAL FOR IGNITION?

NORMAL MAIN BURNER OPERATION.

FLAME SIGNAL LOST?

CALL FOR HEAT ENDS (24 VAC INPUT REMOVED

FROM 24 VAC TERMINAL).

MAIN BURNER OFF.

MAIN VALVE STAYS OPEN;

SPARK GENERATOR POWERED.

1 HOUR AUTO RESET TIME.

START

SAFE START

CHECK/

PREPURGE

TRIAL FOR

IGNITION

MAIN

BURNER

OPERATION

END

NO

NO

NO

NO

YES

NO

YES

YES

NO

YES

YES

M16530

WAIT 4 SEC. FLAME

STILL DETECTED?

YES

LOCKOUT WITH

LED ON STEADY.

MAIN VALVE CLOSES;

SPARK GENERATOR OFF.

LOCKOUT WITH LED ON STEADY

MAIN BURNER LIGHTS AND FLAME

SENSED DURING TRIAL FOR IGNITION?

NOTES:

— WHEN CONTROL IS IN LOCKOUT, ALARM OUTPUT (IF PROVIDED) IS ENERGIZED.

— LED FLASHES AT HEARTBEAT SPEED DURING ALL NORMAL OPERATION.

RETRY COUNT

LESS THAN 2?

30 SEC. BETWEEN

TRIAL PURGE.

Содержание S8700 Series

Страница 11: ...11 69 1299 ...