C7012A,C,E,F,G SOLID STATE PURPLE PEEPER® ULTRAVIOLET FLAME DETECTORS

60-2398-17

8

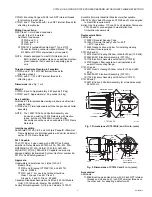

Fig. 7. Mounting C7012A, E, or G Detector.

To mount a C7012C or F with explosion-proof housing (Fig. 8):

1.

Unscrew the collar on the pipe union and remove the

coupling section. The collar and coupling are in two

pieces; do not separate them.

2.

Screw the coupling onto the sight pipe, reducer, or other

fitting.

3.

Mount the remainder of the pipe union (with the detector)

onto the coupling and securely tighten the collar.

Wiring (Fig. 9-16)

CAUTION

Equipment Damage Hazard.

Improper wiring can permanently damage

amplifier.

When using a C7012E or F with an R7247C, R7847C

Dynamic Self-Check Amplifier, be careful not to short

the white shutter leadwires together (by wiring

incorrectly, leaving an incorrect jumper wire, or

stripping the insulation too much so the bare leadwires

can touch).

Fig. 8. Mounting C7012C or F Detector.

IMPORTANT

Certain C7012E and all G models are designed to

meet DIN and BGC requirements. They have an addi-

tional yellow/green grounding leadwire; connect this

wire to a separate ground terminal on the wiring sub-

base.

1.

All wiring must comply with applicable local electrical

codes, ordinances and regulations.

NOTE: The detector has color-coded and labeled, plastic

insulated, no. 18 leadwires, 8 feet (2/4 m) long, rated

for 221°F (105°C).

2.

Keep the flame signal leadwires as short as possible

from the flame detector to the terminal strip or wiring

subbase.

NOTE: Capacitance increases with leadwire length, reducing

the signal strength. The maximum permissible

leadwire length depends on the type of leadwire,

conduit type and diameter. The ultimate limiting factor

in flame signal leadwire length is the signal current or

voltage at the flame safeguard device. Refer to Table

1.

3.

Detector leadwires can be spliced for longer leadwire

runs, observing the following considerations (see Fig. 9):

a. Make required splices in a junction box.

b. Use moisture-resistant no. 14 wire suitable for at

least 167°F (75°C).

c. For high temperature installations, use Honeywell

specification No. 32004766-003 or equivalent for the

F leadwire. This wire is rated up to 400°F (250°C) for

continuous duty. It it tested for operation up to 20,000

volts and for breakdown up to 32,000 volts. For the

other leadwires, use moisture-resistant no. 14 wire

selected for a temperature rating above the maxi-

mum operating temperature.

d. F and G wires (blue and yellow) must be run in their

own conduit independent of other power carrying

leadwires. More than one set of scanner F and G

wires can be run in the same conduit.

e. A shielded twisted pair wire may be substituted for

conduit for routing the F leadwire (blue). Be advised

of the capacitance per foot of shielded wire effec-

tively reduces the flame signal at the flame safe-

guard device. Be sure to ground the shield to the G

terminal at the flame safeguard wiring subbase.

f. The detector power and shutter wires need to be run

in their own conduit as well, avoiding other electrical

noise carrying wiring.

g. The scanner wires should remain separated a mini-

mum of 2 inches from other line voltage wires in the

main control panel to the flame safeguard device.

4.

The following installation considerations can influence

detector operation and maximum leadwire length and

should be avoided:

a. Moisture.

b. Ignition interference.

c. high resistance connections or poor grounds.

d. Leadwire capacitance.

e. Voltage fluctuations.

f. Induced line transients.

g. Floating grounds—ground at some voltage above

earth ground.

h. No G wire—burner used as ground.

i.

Detector output less than maximum attainable for the

installation (inadequate sighting).

5.

Refer to Fig. 10 through 17 for wiring connections.

ROTATE DETECTOR THIS

WAY WHEN MOUNTING

NOTCH IN FACEPLAGE

(C7012E ONLY)

ROTATE

DETECTOR

THIS WAY TO

SEPARATE

MOUNTING

FLANGE

SCREW ONTO

SIGHT

PIPE

SLOT (3)

M24002

COVER

FACEPLATE

FLANGE

SCREWS (3)

BACK SECTION OF

MOUNTING FLANGE

CAPTIVE COVER

SCREWS (4)

124198 (1 IN. NPT) SHOWN

FRONT SECTION OF

MOUNTING FLANGE

COVER

HEX-HEAD

COVER BOLT (6)

BODY FLANGE

PIPE

UNION

COLLAR

SCREW COUPLING

ONTO SIGHT PIPE

HOLE

KEYED

TO PIN

ON BODY

FLANGE

M1955