C7012A,C,E,F,G SOLID STATE PURPLE PEEPER® ULTRAVIOLET FLAME DETECTORS

5

60-2398-17

Clearance

Make sure there is enough room to easily mount the sight pipe,

detector and all required fittings, and to remove the detector for

troubleshooting and servicing.

Radiation Sources (Other Than

Flame)

Examples of radiation sources (other than flame) that could

actuate the detection system:

1.

Ultraviolet sources:

a. Hot refractory above 2300°F (1260°C).

b. Spark:

(1) Ignition transformers.

(2) Welding arcs.

(3) Lightning.

c. Welding flames.

d. Bright incandescent or fluorescent artificial light.

e. Solar radiation.

f. Gas lasers.

g. Sun lamps.

h. Germicidal lamps.

i.

Bright flashlight held close to sensing tube.

2.

Gamma ray and X-ray sources:

a. Diffraction analyzers.

b. Electron microscopes.

c. Radiographic X-ray machines.

d. High voltage vacuum switches.

e. High voltage condensers.

f. High voltage coronas.

g. Radioisotopes.

Except under unusual circumstances, none of these sources

except hot refractory and ignition spark would be present in or

near the combustion chamber.

The detector may respond to hot refractory above 2300°F

(1260°C) if the refractory surface represents a significant

percentage of the detector field of view. If the temperature of

the hot refractory causes the flame relay (in the flame

safeguard control) to pull in, re-aim the sight pipe so the

detector views a cooler area of the refractory.

Ignition spark is an intense source of ultraviolet radiation.

When installing the detector, make sure it does not respond to

ignition spark.

Single Burner Requirements

The detector must have an unobstructed view of a steady part

of the flame it is supervising. This requires a proper sighting

angle and minimized ultraviolet radiation attenuation effects.

Supervising only one burner simplifies sighting requirements.

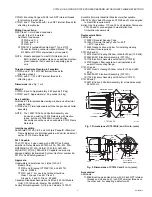

Sighting Angle (Fig. 3)

The first 30 percent of a flame closest to the burner nozzle (the

flame root) emits the most ultraviolet energy. Also, if the

detector sights the flame at an angle instead of

perpendicularly, it views more flame depth. Therefore, the best

sighting angle is nearly parallel to the axis of the flame,

permitting the detector to view a large portion of the first 30

percent of the flame closest to the burner nozzle, as illustrated

in Fig. 3.

Low angle sighting permits the detector to view a greater depth

of flame, thus reducing the effects of instabilities in the flame

pattern. Also, the environment near the burner nozzle is

usually cleaner than at any other part of the combustion

chamber. This provides a clearer line of sight and can keep the

viewing window cleaner, thus reducing the maintenance

required.

Fig. 3. Detector sighting angle.

NOTE: When possible, it is desirable to tilt the detector and

sight pipe downward to prevent the buildup of soot in

the pipe or on the viewing window.

In most installations, the detector needs to respond to the pilot

flame alone, then the pilot and main burner flame together, and

finally the main burner flame alone. The detector must meet all

sighting requirements that apply:

Pilot flame alone—the smallest pilot flame that can be

detected must be capable of reliably igniting the

main burner.

Pilot and main burner flame together—the detector must

sight the junction of both flames.

Main burner flame alone—the detector must sight the most

stable part of the flame for all firing rates.

Parallel Flame Detectors

Shifting flame patterns, commonly encountered on burners

with high turndown ratios, can require two parallel detectors to

prove the flame at the highest and lowest firing rates and for

modulation in between. In this case, one detector supervises

the pilot (interrupted) and both detectors supervise the main

burner flame. During the main burner run period, either

detector is capable of maintaining system operation. A

maximum of two C7012 Detectors can be connected in

parallel.

In addition to assuring more reliable flame detection, parallel

detectors facilitate maintenance during burner operation. Each

detector can be removed, in turn, without shutting down the

supervised burner. However, a flame simulating failure

occurring in the flame signal amplifier or in either detector

causes a shutdown.

FLAME DEPTH–

ANGLE VIEW

M1956

DETECTOR IN GOOD

SIGHTING POSITION

(LOW ANGLE SIGHTING)

UNBURNED FUEL

FLAME DEPTH–

PERPENDICULAR VIEW

BURNER

NOZZLE

DETECTOR IN POOR

SIGHTING POSITION