MSXX10, MSXX20 SERIES

63-2607—26

2

1

Number represents range

2

All spring return actuators have <25 second spring return time

3

0/2-10 Vdc

4

45 second drive has 15 VA for MSxx10 and 22 VA driving for MSxx20

SPECIFICATIONS

Models:

See Tables 2 and 4.

NOTE:

This document also covers the MS7110K and

MS7106K.

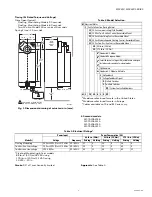

Dimensions:

Device Weight:

6 lb (2.7 kg).

Temperature Ratings:

Ambient: -40°F to 140°F (-40°C to 60°C).

Shipping and Storage: -40°F to 158°F (-40°C to 70°C).

Humidity Ratings:

5% to 95% RH noncondensing.

Electrical Connections:

Field wiring 14 to 22 AWG (2.0 to 0.344 mm sq) to screw

terminals, located under the removable access cover.

Electrical Ratings:

End Switches (Two SPDT):

Dry Contact

Settings (fixed): 7° nominal stroke, 85° nominal stroke.

Ratings (maximum load): 250 Vac, 5A resistive.

Mounting:

Self-centering shaft adapter (shaft coupling).

Round Damper Shafts: 0.375 to 1.06 in. (10 to 27 mm).

Square Damper Shafts: 1/2 to 3/4 in. (13 to 19 mm).

Actuator can be mounted with shaft in any position.

NOTE:

For 175 lb-in. (20 Nm) models: 3/4 in. or greater

shaft diameter recommended.

Minimum Damper Shaft Length:

1 in. (25 mm); 3 in.

(76 mm) recommended.

Cable Specification:

300 V, 75° C, Plenum Rated, 3 ft length from end of access

cover, 18 AWG

Table 1. Features

Model

Number

Model

Number

(including 3

ft. whip)

Torque

Power Supply

Drive

2

(sec)

Control Input/Output

Description

SPDT Aux

Switch

Voltage

VA

Driving

1

MS7510A2008 MS7510W2008

88 lb-in

(10 Nm)

24 Vac/dc

14

90

Floating, Modulating

3

,

Two-Position (SPST),

Feedback

0

MS7510A2206 MS7510W2206

2

MS7510H2209

Floating, Modulating

3

,

Feedback, Two-Position

(SPST), Adj. Zero & Span

2

MS8110A1008 MS8110W1008

30

45

Two-Position (SPST)

0

MS8110A1206 MS8110W1206

2

MS4110A1002

100-250 Vac

45

45

Two-Position (SPST)

0

MS4110A1200

2

MS3110J1008

24 Vac/dc

14

4

90

Sylk Enabled

0

MS3110J1206

24 Vac/dc

14

4

90

Sylk Enabled

2

MS7520A2007 MS7520W2007

175 lb-in

(20 Nm)

24 Vac/dc

16

90

Floating, Modulating

3

,

Two-Position (SPST),

Feedback

0

MS7520A2205 MS7520W2205

2

MS7520H2208

Floating, Modulating

3

,

Two-Position (SPST),

Feedback, Adj. Zero & Span

2

MS8120A1007 MS8120W1007

40

45

Two-Position (SPST)

0

MS8120A1205 MS8120W1205

2

MS4120A1001

100-250 Vac

60

45

Two-Position (SPST)

0

MS4120A1209

2

MS3120J1007

24 Vac/dc

16

4

90

Sylk Enabled

0

MS3120J1205

24 Vac/dc

16

4

90

Sylk Enabled

2