SERIES 71, 72, AND 76 MODUTROL IV™ MOTORS

7

63-2640—07

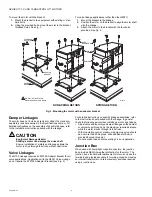

Fig. 4. Mounting the motor on a Q5001 Valve Linkage.

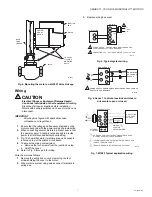

Wiring

CAUTION

Electrical Shock or Equipment Damage Hazard.

Can shock individuals or short equipment circuitry.

Disconnect all power supplies before installation.

Motors with auxiliary switches can have more than one

disconnect.

IMPORTANT

All wiring must agree with applicable codes,

ordinances and regulations.

1.

Ensure that the voltage and frequency stamped on the

motor correspond with the power supply characteristics.

2.

When connecting several motors in parallel, ensure that

the power supply VA rating is large enough to provide

power to all motors used without overloading.

3.

Fig. 10 shows that motor terminals are quick-connects

located on top of the printed circuit board.

4.

To access the wiring compartment:

a. Remove the four screws from the junction box top.

b. Lift off the cover.

5.

Refer to Fig. 5 through 8 for wiring.

Wire the motor as follows:

1.

Remove the wiring box cover by removing the four

screws holding the cover to the motor.

2.

Wire motor to system using quick-connect terminals in

wiring box.

3.

Replace wiring box cover.

Fig. 5. Typical system wiring.

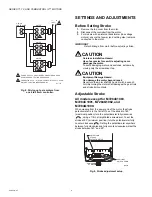

Fig. 6. Series 71 optional override switches to

drive motor open or closed.

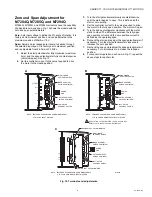

Fig. 7. M7685 Typical application wiring.

1/4-20 UNC

1 in. LONG

MOUNTING

BOLTS

Q5001

VALVE

LINKAGE

M18994

MOTOR

JUNCTION

BOX

POWER

END OF

MOTOR

VALVE

CONTROLLER

L1

(HOT)

L2

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND

OVERLOAD PROTECTION AS REQURED.

CONNECTING F TO – WILL DRIVE MOTOR TO FULLY OPEN.

1

M5778

1

-

MOTOR

2

F

T1

T2

2

+

-

+

24V

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

PROTECTION AS REQUIRED.

M13726

L1

L2

R

MODULATING

DC VOLTAGE

SOURCE

1

L1

L2

(HOT)

+

C

F

1

DAMPER MOTOR

1

2

3

T1

T2

C

R

4

3

1

L1

L2

(HOT)

+

-

2

2

3

DAMPER MOTORS

WHITE

RED

MODULATING

dc VOLTAGE

SOURCE

MINIMUM

POSITION

POTENTIOMETER

EXTERNAL

CONTROL

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND

OVERLAOD PROTECTION AS REQUIRED.

IF MINIMUM POSITION POTENTIOMENTER IS NOT USED,

JUMPER TERMIALS 3 AND 4.

TRANSFORMER MAY BE INTERNAL OR EXTERNAL.

M13727