SERIES 71, 72, AND 76 MODUTROL IV™ MOTORS

11

63-2640—07

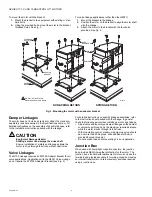

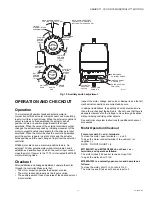

Fig. 12. Auxiliary switch adjustment.

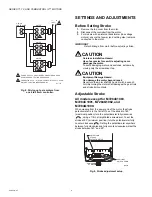

OPERATION AND CHECKOUT

Operation

The internal shaft position feedback potentiometer in

conjunction with the actuator microprocessor and modulating

input circuit form a control loop. When the external controller’s

output remains at a fixed amplitude the actuator’s shaft

position is held at a position proportional to that input

amplitude. When the value of the external controllers output

changes the actuator responds by initiating movement of the

motor to proportionately compensate for the change in input

amplitude. When the motor reaches the control loop balance

point the system is again in a static state and the actuator

holds position until the next change of input from the external

controller.

M7685 motor also have a minimum position feature. An

external 130 ohm potentiometer wired to terminals 3 and 4

establishes a position beyond which the control input cannot

close the motor. If power to the T1-T2 is interrupted the M7685

motor will spring close.

Checkout

After installation and linkage adjustment, operate the motor

through the controller. Make sure that:

• The motor properly operates the damper or valve.

• The motor responds properly as the input is varied.

• The auxiliary switch, if used, operates at the desired point of

motor rotation.

Inspect the motor, linkage, and valve or damper to see that all

mechanical connections are correct and secure.

In damper installations, the pushrod should not extend more

than a few inches past the ball joints. Check to see that there is

adequate clearance for the linkage to move through its stroke

without binding or striking other objects.

See controller or system instructions for additional checkout

procedures.

Motor Operation Checkout

For motors with F, + and - terminals:

To close the motor, open ter, -, and F.

To open the motor connect terminal F to positive (+) or

negative (-).

NOTE: DO NOT SHORT + to -

M7164A1017 and M7164G1030 do not have + or –

terminals, and operate as follows:

The motor closes if it does not receive an input to F.

To open the motor, short F to C.

M7685A1025 is a normally open motor, and operates as

follows:

To close the motor, short 3 to 4 or short 3 to C.

The motor opens if it does not have an input to 3.

RIGHT/INNER

AUXILIARY

SWITCH

FAST RISE

PORTION

(APPROX.

1 DIFF.)

SLOW RISE

PORTION

(APPROX.

10 DIFF.)

INNER

AUXILIARY

CAM

(BLUE)

NOTE: CAMS ARE OFFSET

VERTICALLY TO PROVIDE

BETTER VIEW OF BACK CAM.

FAST RISE

PORTION

(APPROX.

1 DIFF.)

SLOW RISE

PORTION

(APPROX.

10 DIFF.)

MOTOR

OPEN

MOTOR

CLOSE

POWER

END

OUTER

AUXILIARY

CAM

(RED)

LEFT/OUTER

AUXILIARY

SWITCH

M17101

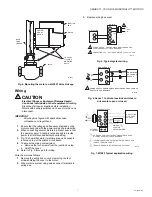

POWER END

OF MOTOR

OUTER AUXILIARY

CAM (RED)

INNER AUXILIARY

CAM (BLUE)

RIGHT/INNER

AUXILIARY SWITCH

LEFT/OUTER

AUXILIARY

SWITCH

MOVE SCREWDRIVER AT

TOP ONLY TO ADJUST CAM.

1/8 INCH

STRAIGHT-BLADE

SCREWDRIVER