SERIES 71, 72, AND 76 MODUTROL IV™ MOTORS

63-2640—07

10

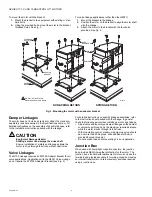

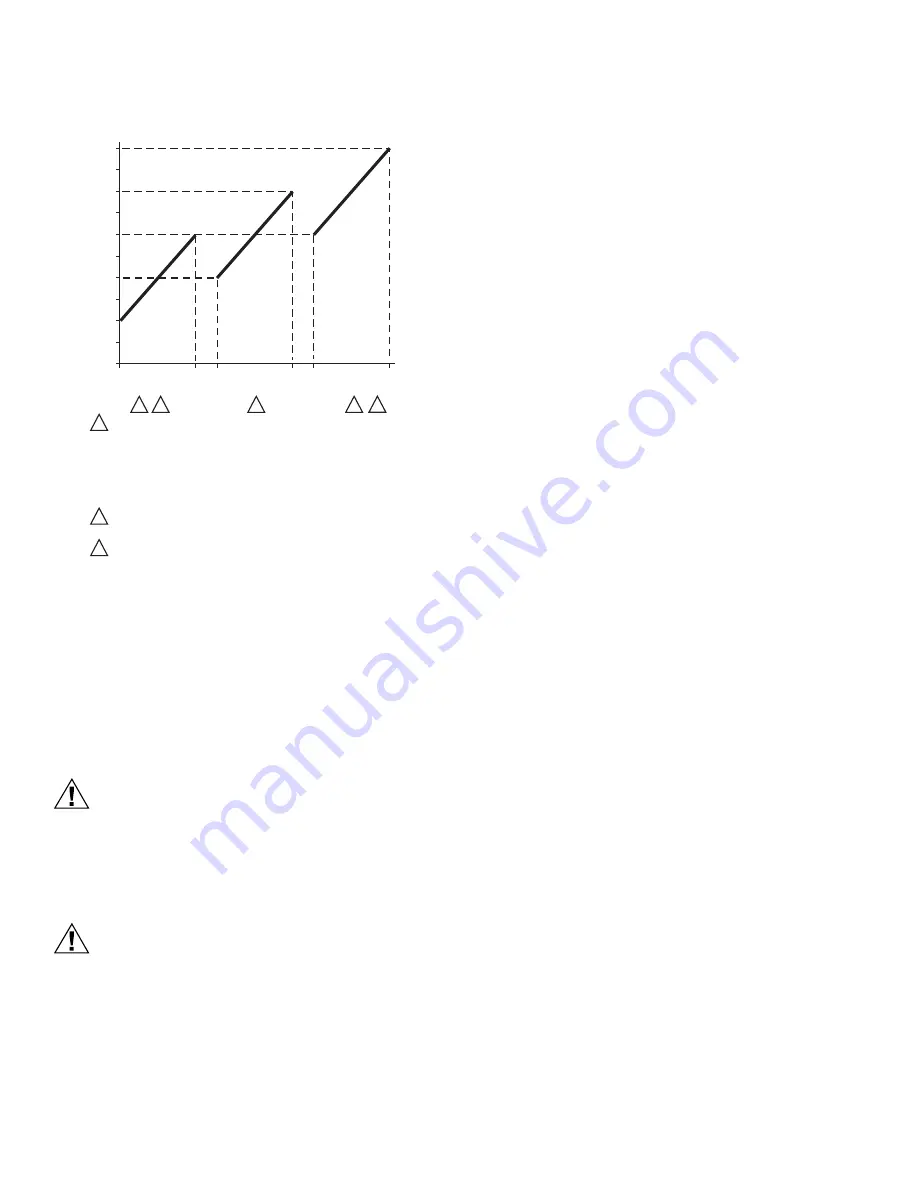

Fig. 11. Sequential operation of motors.

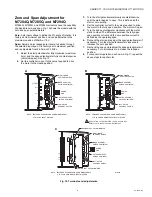

Enhanced Resolution

M7284C1083, M7284C1091, M7284Q1082,

and M7284Q1090

These four motors have enhanced resolution with 160

repositions (steps) from 90 degrees to 160 degrees stroke.

Auxiliary Switches

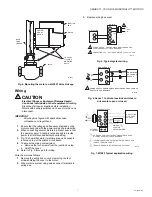

CAUTION

Electrical Shock or Equipment Damage Hazard.

Can shock individuals or short equipment

circuitry.

Disconnect all power supplies before installation.

Motors with auxiliary switches can have more than one

disconnect.

CAUTION

Equipment Damage Hazard.

Can damage the motor beyond repair.

Never turn the motor shaft by hand or with a wrench.

Forcibly turning the motor shaft damages the gear train

and stroke limit contacts.

Adjustable cams actuate the auxiliary switches. These cams

can be set to actuate the switches at any angle within the

motor stroke. Select switch differential of 1° or 10°.

Motors with factory added auxiliary switches are shipped in the

closed position (fully counterclockwise, as viewed from the

motor power end) with auxiliary cams set to actuate switches

30° from the closed position and to provide 1° degree

differential. With the motor in the closed (fully counter-

clockwise) position, the auxiliary switch breaks contacts R-B.

See Fig. 12 for auxiliary switch wiring.

Series 2 Motors are shipped with auxiliary switch cams that

permit acceptance of 220736A,B Internal Auxiliary Switch Kits.

Refer to form 63-2228 for 220736A,B Installation Instructions.

Auxiliary Switch Adjustment

IMPORTANT

When adjusting the auxiliary switch cams use the

following procedure:

1. Insert 1/8 in. screwdriver blade into a slot on cam and

move the screwdriver top as far as possible in the

required direction. See Fig. 12.

2. Repeat step 1 in successive cam slots until the cam is

in the required position.

NOTE: Series 2 Motors are shipped with auxiliary switch

cams that permit acceptance of 220736A,B Internal

Auxiliary Switch Kits. Refer to Form no. 63-2228 for

220736A,B Installation Instructions.

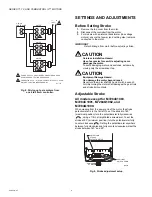

Use the following procedure to obtain the desired auxiliary

switch settings:

1.

Remove the top cover from the motor to gain access

to the motor terminals and auxiliary cams.

2.

Disconnect the controller from the motor.

3.

Connect a current source to the positive and negative

terminals.

4.

Drive the motor to the position where the auxiliary equip-

ment is to be switched by increasing or decreasing the

current.

5.

For a switch differential of 1°, check continuity of auxiliary

switch contacts R-B and rotate the cam as follows:

a. If the contacts are open, rotate the cam clockwise

until the R-B contacts close.

b. If the contacts are closed, rotate the cam

counterclockwise until the R-B contacts open.

6.

For a switch differential of 10° rotate the cam

approximately 180° so the slow-rise portion of the

cam actuates the switch.

7.

Check continuity of the auxiliary switch contacts R-B.

8.

Rotate the cam as follows:

a. If the contacts are open, rotate the cam

counterclockwise until the R-B contacts close.

b. If the contacts are closed, rotate the cam clockwise

until the R-B contacts open.

c. Make final adjustment in the proper direction to

obtain contact make or break at the desired position.

9.

Check for the proper differential and switching of the

auxiliary equipment by driving the motor though the full

stroke in both directions.

10.

Disconnect power, remove current source, reconnect the

controller, and replace the top cover on the motor.

NOTE: Changing the differential from 1° to 10° reverses the

switching action. For example, with a 10° differential,

switch contacts R-B make and R-W break on a

counterclockwise (closed) rotation. With a 1°

differential, switch contacts R-W make and R-B break

on a counterclockwise (closed) rotation.

20

(10)

16

(8)

12

(6)

8

(4)

4

(2)

0

CONTROL OUTPUT

mA CURRENT (OR VOLTS DC)

CLOSED

OPEN

CLOSED

OPEN

CLOSED

OPEN

MOTOR 1

MOTOR 2

MOTOR 3

1

3

3

3

1 MOTOR 1 PROPORTIONS BETWEEN 4 AND 12 mA; FULLY

CLOSED AT 4 mA, FULLY OPENED AT 12 mA.

MOTOR 2 PROPORTIONS BETWEEN 8 AND 16 mA; FULLY

CLOSED AT 8 mA, FULLY OPENED AT 16 mA.

MOTOR 3 PROPORTIONS BETWEEN 12 AND 20 mA SIGNAL;

FULLY CLOSED AT 12 mA, FULLY OPENED AT 20 mA.

UP TO 6 MOTORS CAN BE DRIVEN SEQUENTIALY OR IN

UNISON FROM ONE CONTROLLER.

ADJUST ZERO ADJUST AND SPAN ADJUST POTENTIOMETERS

TO ACHIEVE DESIRED SEQUENCE.

2

2

3

SEQUENTIAL OPERATION

FOR ADJUSTABLE ZERO AND SPAN MODELS

M2893A