ML6174, ML7174 NON-SPRING RETURN DIRECT COUPLED ACTUATORS

63-2534—1

8

All wiring must comply with local electrical codes, ordinances

and regulations. Voltage and frequency of the transformer

used with the ML6174 must correspond with the

characteristics of the power supply and of the actuator. Screw

terminals are provided for easy hookup. See Fig. 10, 11 and

13-17 for typical wiring hookups.

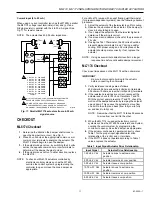

Connecting Wiring to Conduit Cover Actuators

(Fig. 9)

1.

Remove the cover from the actuator by lifting the top

and pivoting the cover to the rear of the actuator.

2.

Remove the conduit knockouts with a flat-bladed

screwdriver. Discard the knockouts.

3.

Install the conduit connector.

4.

Run the connecting wire through the conduit connector,

strip the wire ends (if necessary) and connect to the

CW, COM and CCW terminals using Fig. 10, 11 or the

control manufacturer instructions.

COVER

M10075

CONDUIT

KNOCKOUTS

Fig. 9. Conduit cover for ML6174/ML7174 DCA.

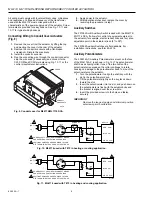

Fig. 10. ML6174 used with T87F in heating or cooling application.

Fig. 11. ML6174 used with T87F in heating and cooling application.

5.

Apply power to the actuator.

6.

After operational checkout, replace the cover by

reversing the procedure in step 1.

Auxiliary Switches

The 201052A or B Auxiliary Switch is used with the ML6174/

ML7174 DCA. It allows for control of equipment external to

the actuator (for example, electric reheat coils and fan) at an

adjustable point in the actuator stroke (0

°

to 90

°

).

The 201052 Auxiliary Switches are field-addable. For

installation instructions, see form 63-2218.

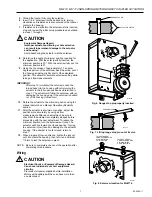

Auxiliary Potentiometers

The 200976A,C Auxiliary Potentiometers mount on the face

of the ML6174A,C (as shown in Fig. 12). The potentiometer

shaft has a slipping collar. If one of the two limits of the

potentiometer is exceeded, the collar continues to rotate,

causing no damage to the potentiometer itself. To mount the

potentiometer on the actuator:

1.

Turn the potentiometer to align the shaft key with the

slot in the potentiometer drive.

2.

Tilt the potentiometer slightly so the key faces down

toward the slot.

3.

Insert the potentiometer into the slot, and push down so

the potentiometer is flush with the actuator body and

the bracket is aligned over the screw hole.

4.

Insert the provided screw into the hole and fasten

securely.

IMPORTANT

Remove the range stop pins and minimum position

setscrews prior to calibration.

M10248

EXTERNAL

SWITCH

R

W

Y

T87F

R8222

#1

#2

#3

RED COM

BLUE CW

WHITE CCW

L1

(HOT)

L2

1

1

2

2

POWER SUPPLY. PROVIDE DISCONNECT MEANS

AND OVERLOAD PROTECTION AS REQUIRED.

AUXILIARY SWITCHES ARE REQUIRED TO TURN

OFF THE MOTOR AT EACH END OF THE STROKE.

ML6174

M10249

R

W

Y

T87F

R8222

#1

#2

#3

RED COM

BLUE CW

WHITE CCW

L1

(HOT)

L2

1

ML6174

1

2

2

POWER SUPPLY. PROVIDE DISCONNECT MEANS

AND OVERLOAD PROTECTION AS REQUIRED.

AUXILIARY SWITCHES ARE REQUIRED TO TURN

OFF THE MOTOR AT EACH END OF THE STROKE.