ML6174, ML7174 NON-SPRING RETURN DIRECT COUPLED ACTUATORS

63-2534—1

6

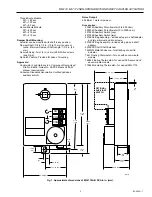

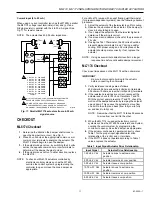

Fig. 4. Using damper shaft adapter for 3/8 in.

damper shafts.

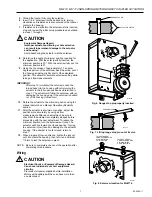

Manual Operation (Declutch)

CAUTION

Personal Injury and Product Damage Hazard.

Do not use manual declutch without supporting

the load.

Support load independent of actuator immediately

prior to and while using manual declutch lever.

Use the manual declutch lever to manually adjust the actuator

setting. Fig. 5 shows the location of the manual declutch

lever. To operate, push the lever in the direction of the arrow

on the lever cover.

SHAFT ADAPTER

M2064

M10076A

MANUAL

DECLUTCH

LEVER

60

°

60

°

Fig. 5. Location of manual declutch lever.

Installation

After determining the direction of the damper shaft rotation

(cw or ccw), proceed as follows:

1.

Place the actuator onto the damper shaft.

2.

If the angle of the damper opening is 60

°

, close the

actuator using the manual declutch:

a.

Disengage the hub using the declutch lever; see

Manual Operation (Declutch) section.

b.

Rotate the hub until the actuator gear train

passes the 60

°

setting. (Do not insert the pin until

the actuator has passed this point.)

c.

Release the declutch lever.

NOTE:

Dampers with 90

°

stroke do not require the

range stop pin.

3.

Insert the range stop pin into the appropriate (cw or

ccw) 60

°

slot. The range stop pin is clipped into its final

position only after the pin passes through both actuator

plates (see Fig. 6). The range stop pin should

snap

into

position and not be removable by hand (see Fig. 7).

4.

With the actuator placed in its final position, secure the

mounting tab to the damper box with a sheet metal

screw.

CAUTION

Equipment Damage Hazard.

Tightly securing mounting tab to damper housing

can damage actuator.

Do not fully tighten the screw, when mounting, to

allow the actuator to float.

5.

Position the damper in the open position and tighten

the Allen screws securely into the damper shaft.

6.

If the angle of the damper opening is 45

°

, close the

actuator using the manual declutch.

a.

Disengage the hub using the declutch lever; see

Manual Operation (Declutch) section.

b.

Rotate the hub until the actuator gear train

passes the 45

°

setting. (Do not insert the pin until

the actuator has passed this point.)

c.

Release the declutch lever.

7.

Insert the range stop pin into the appropriate (cw or

ccw) 45

°

slot. The range stop pin is clipped into its final

position only after the pin passes through both actuator

plates (see Fig. 6). The range stop pin should

snap

into

position and not be removable by hand (see Fig. 7).

CAUTION

Equipment Damage Hazard.

Using incorrect range stop can damage light duty

dampers.

Be sure to select the correct range stop.

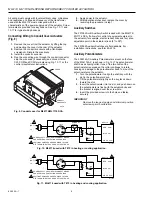

Minimum Position Setscrew

Certain ML6174 and all ML7174 models are equipped with

two tapped holes located in the plastic housing at the top of

the actuator. These holes can be used with the minimum

position setscrew and locknut inside the 4074ENJ Bag

Assembly (see Fig. 8). The setscrew provides for a 0

°

to 30

°

minimum position adjustment.

NOTE:

Before starting operation, note that the 1/4 in.

minimum position setscrew limits closing motion,

while the range stop pin limits opening motion.

1.

Determine the direction of the desired closing rotation.

2.

Move the actuator to the position fully opposite of the

desired closing rotation (if cw closing rotation is

desired, move the actuator to the full ccw position).

3.

Establish the correct hole for the setscrew using Fig. 8

and the results of step 1.

4.

Remove the red cap from the desired hole. Leave the

other cap in position. The caps ensure that dust and

other impurities do not enter the gear train through

unused holes.