MeshGuard User’s Guide

23

5.4.6 Change Low Alarm

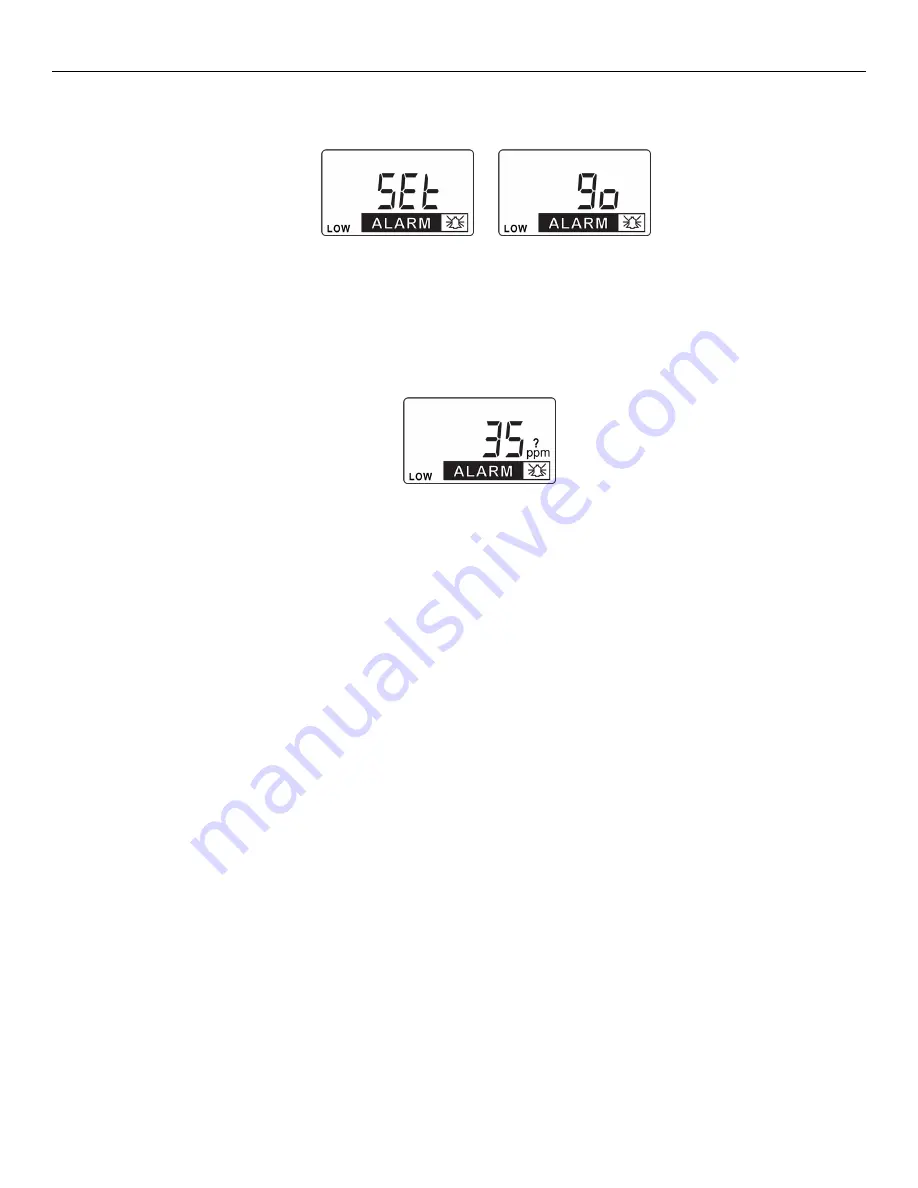

At the Change Low Alarm menu, “Set” and “go” flash in alternation, and “LOW” and “ALARM” are visible in the

display.

Note:

It is not recommended to increase the Low Alarm setting above the factory default value.

Note:

The Low Alarm value varies by sensor type.

Press [Y/+] to enter and change the setting. Press [MODE] to exit and return to Detection Mode or [N] to advance to

the next menu.

The LCD displays current value. Change the value if necessary.

To change the value:

1. Press [Y/+] to increase the number and [N/-] to decrease it.

2. Press [MODE] to advance to the next digit.

3. After moving to the last digit and making changes, press [MODE]. A question mark (?) is shown in the

display, asking if you want to save the change.

•

Press [Y/+] for yes. The message “dn” means the change is done.

•

Press [N/-] for no. A “no” message means that the change was abandoned.

•

Press [MODE] to return to the first digit.