3

EN2C-0112SZ20 R0202

Diagram Shaft Drive

Load torque

Holding

Voltage

Type

Remarks

time

torque

Nr.

Nr.

s

Nm

Nm

V

S1

5

5

2,5

0,8

230

LKS 160-01

A 5-5 S1

standard version

S2

5

5

2,5

0,8

230

LKS 160-03

A 5-5 S2

standard version

S1

5

12

3

1,5

230

LKS 160-07

A 5-12 S1

S1

5

5

2,5

0,8

230

LKS 160-09

A 5-5 S1

Spindle-driven cam

S7

5

30

3

3

24

LKS 160-22

A 5-30 S7

S7.1

5

30

3

3

110

LKS 160-24

A 5-30 S7.1

S6

5

34

3

3

230

LKS 160-25

A 5-34 S6

S1.2

5

34

3

3

230

LKS 160-26

A 5-34 S1.2

S1

5

12

3

1,5

230

LKS 160-37

A 5-12 S1

S4

5

5

2,5

0,8

230

LKS 160-39

A 5-5 S4

S2

5

3

1,5

0,6

230

LKS 160-40

A 5-3 S2

S13

5

45

3

3

230

LKS 160-42

A 6-45 S13

Spindle-driven cam

S8.P1.1

5

34

3

3

230

LKS 160-44

A 5-34 S8.P1.1

Potentiometer can be retrofitted

S8.P2

5

30

3

3

110

LKS 160-55

A 5-30 S8.P2

Potentiometer can be retrofitted

S8.P4

5

45

3

3

230

LKS 160-59

A 5-45 S8.P4

with Potentiometer, special circuit

S8.P

6

34

3

3

230

LKS 160-63

A 6-34 S8.P

Potentiometer can be retrofitted

S8.P4.1

5

38

3

3

120

LKS 160-65

A 5-38 S8.P4.1

Run time at 60 Hz, with Potentiometer,

special circuit

S8.P3

5

30

3

3

24

LKS 160-67

A 5-30 S8.P3

Potentiometer can be retrofitted

S8.P1.1

5

34

3

3

230

LKS 160-68

A 5-34 S8.P1.1

Potentiometer can be retrofitted,

spindle-driven cam

S8.P1

5

5

2,5

0,8

230

LKS 160-70

A 5-5 S8.P1

S4

5

3

1,5

0,6

230

LKS 160-73

A 5-3 S4

S15

5

5

2,5

0,8

230

LKS 160-75

A 5-5 S15

For 3-stage operation

S2

5

12

3

1,5

230

LKS 160-79

A 5-12 S2

2 )

3 )

4 )

6 )

5 )

7 )

1 )

SPECIFICATION

TECHNICAL DATA

Type overview

clockwise rotation

Legend

1) when viewing from direction A (see dimensional drawing)

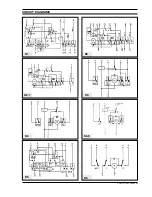

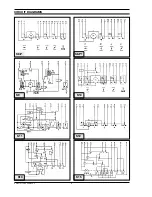

2) see “Circuit diagrams”

3) see “Dimensional drawing”

4) at 50 Hz for 90

°

at 60 Hz, Drive times are about 20 % shorter

5)

under nominal conditions

under extreme conditions (e.g. +60

°

C, 230V -15%) the torques will be 25% lower

6)

+10% -15%; 50...60Hz

at -15%; torque reduced by approx. 20% at undervoltage

7)

Standard: Lever-operated cam