17

cOnTROL FUncTiOnS

TRiM LEvERS anD cOnTROL LinkagE SETUP

To ensure that your aircraft's servos and control linkages operate without binding, it's important that you adjust the control linkages

correctly. Incorrectly adjusting your aircraft's control linkages can result in damage to your aircraft's control surfaces, linkages and/or

damage to the servos.

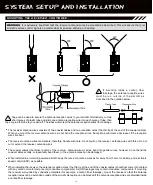

Centering Your Aircraft's Servos and Control Surfaces

1) Turn the transmitter and receiver ON.

2) Center each of the four trim levers. This will ensure that the servo output

shafts are in their neutral positions.

3) Move the control sticks to verify that the servos are moving the correct

direction. If one or more servos are moving the wrong direction, use the

Servo Reversing switches to change the direction of servo travel.

5) With the servo horns as close to being centered as possible, mechanically center each of the control surfaces by adjusting the

clevises and/or adjustable pushrod connectors.

The trim levers are used while you're flying to trim your aircraft for level flight. They should not be used to center the servo horns

when you set up your aircraft's control linkages. In most cases you can center the servo horns using the method described

below, however, if the servo horns cannot be perfectly centered, that's okay. Do not use the trim levers to center the servo horns.

Adjusting Your Control Surfaces for Maximum Control Throw

It's important that you adjust your control linkages to ensure that when the control sticks are moved to their stops that the servos do

not buzz and that the control surfaces do not move any more than the maximum control throw necessary. If the servos are buzzing,

this means that they are under load-stress and can be damaged. The control linkages should be adjusted to fix this issue.

1) If you move the control sticks to their stops and the servos travel more than desired and/or buzz, you can decrease control surface

throw by moving the pushrod closer to the center of the servo arm or moving the pushrod further away from the control surface.

2) If you move the control sticks to their stops and the servos don't travel far enough, you can increase control surface throw by

moving the pushrod further out on the servo arm or moving the pushrod closer to the control surface.

After adjusting for Maximum Control Throw, double-check that the control surfaces are still centered. It may be necessary to

mechanically re-center the control surfaces.

In most cases, if the servo horn is off-center by one tooth, you can get the servo horn closer to

being centered by rotating the servo horn 180º and reinstalling it.

4) Install the servo horns onto the servos as close to being centered as possible.

When installing the servo horn onto your throttle servo, in most cases the servo horn should be

installed approximately 30º aft of center to ensure proper throttle control linkage geometry.

After flying your aircraft and using the trim levers to trim your aircraft for level flight, be careful not to move the trim levers or your

aircraft will be out of trim the next time you fly it. We recommend that you mechanically readjust the control linkages to re-center

the trim levers.

Содержание Aero Sport 5

Страница 1: ...1...