Drive User Guide

32

mode has been switched to profile velocity mode.

B. Confirm the content of 0x6061 object has been set to 9. It indicates that the operational

mode has been switched to the cyclic synchronization velocity mode.

(4)

Set up the maximum limit value of moving velocity (0x607F), the maximum limited value of

acceleration/deceleration (0x6083

、

0x6084) and the deceleration value of emergency stop

(0x6085). These units are count base.

(5)

Master station transmits target velocity (0x60FF). The unit is count/s. Motor will operate to the

target velocity.

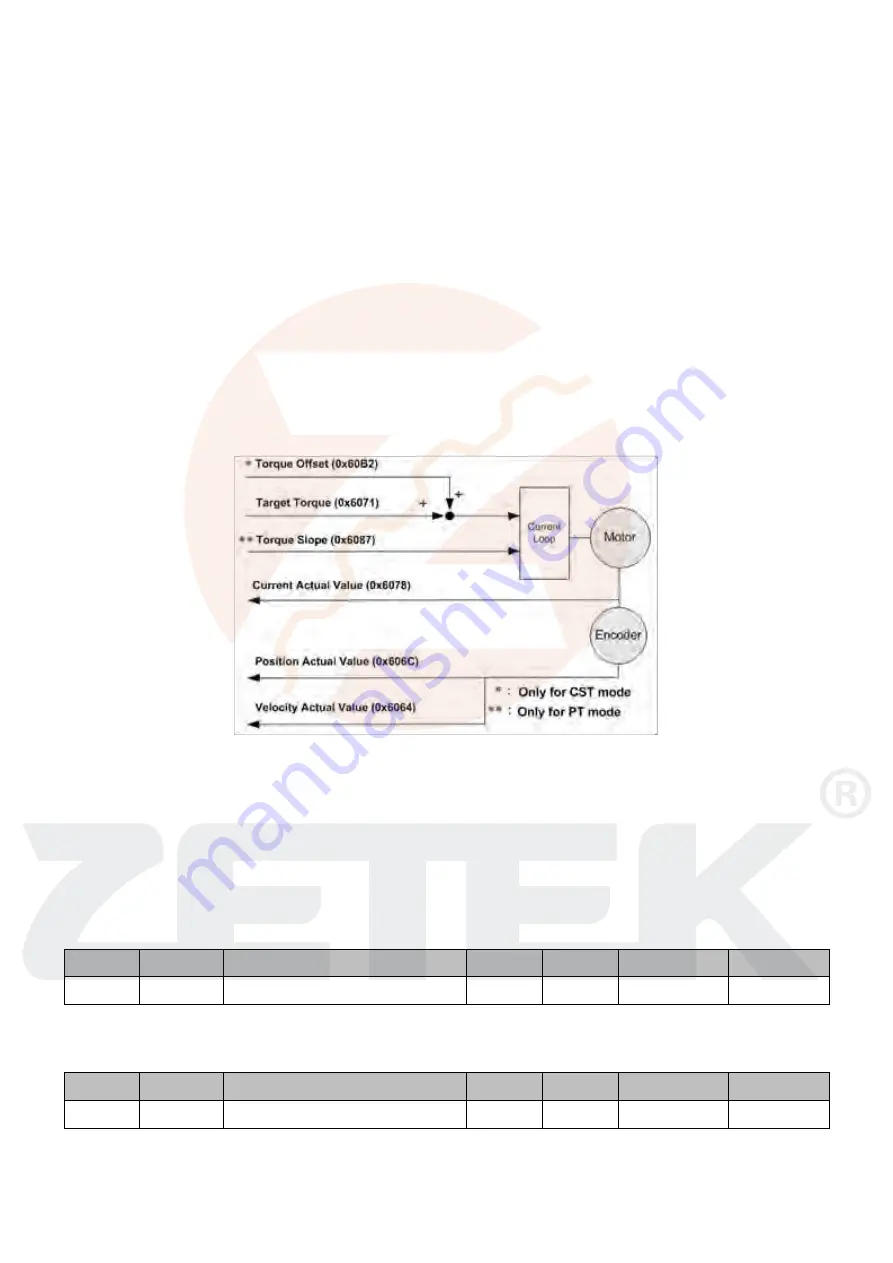

9.3 Torque Control Mode

The figure shown below is the control schematic diagram of profile torque mode (PT) and cyclic

synchronization torque mode (CST). Operating under this mode, drive involves the current loop and

accepts with the target current command transmitted from the master station.

The objects used by the profile torque mode and cyclic synchronization torque mode are listed as

follows:

Target torque (0x6071): The input of target torque is based on the per millage form of motor

continuous current transmitting to the drive. Range is 1000~1000 and the unit is 0.1% of motor

continuous current. Default value is 0. It indicates that the pre-setting current command is 0% of motor

continuous current.

Index

Sub-index

Name

Type

Access

Value

PDO mapping

0x6071

0x00

Current Command (Target Torque)

INT16

RW

-1000~1000

O

Torque slope (0x6087): This is the slope of current command under the set up profile torque mode.

The unit is 0.1%/sec variation of continuous current command and the default value is 1000.

Index

Sub-index

Name

Type

Access

Value

PDO mapping

0x6087

0x00

Current Slope

UINT32

RW

0~4294967295

O

www.servosystem.ru +7(495) 407-01-02