-11-

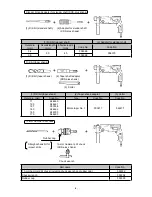

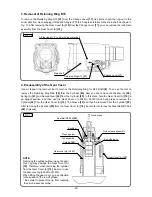

Rod

Air chamber

First gear

Piston pin

O-ring

Armature

Tool shaft

Slip mechanism

Second shaft

Motor shaft

Piston

Strike

Second hammer

Second gear

Cylinder

Ring groove

Reciprocating bearing

Second pinion

Cylinder flange

Second shaft spline

Clutch

Washer

Fig. 3

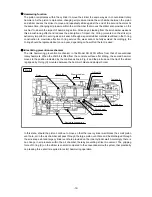

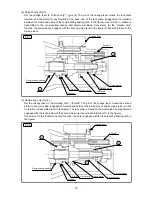

1. Lubrication

Replenish the grease lubricant when disassembling the tool or in case grease leaks due to a defective seal.

Grease must be changed once a year to prolong tool service life. Special grease is used in the striking

section. Should the striking section (inside the gear cover) be disassembled, completely remove the old

grease from all parts and, at reassembly, replenish 30 g of new grease in the gear cover and 10 g in the

groove of the inner cover. Be careful not to exceed the designated amount of grease. Excessive grease will

reduce striking efficiency.

2. Tool Structure

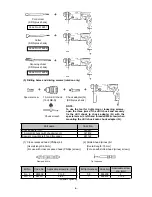

Transmission of rotation

See Fig. 3. Armature rotation is transmitted to the second shaft via the first gear, causing the second

shaft to rotate. The second pinion mounted on the second shaft engages with the second gear mounted

on the outer circumference of the cylinder. The cylinder is coupled to the second gear by means of a slip

mechanism, and both rotate together. The end of the cylinder also functions as the drill bit retainer. The

cylinder is key-connected to the inserted drill bit by means of two key rails and a steel ball, and transmits

rotation to the drill bit.

Piston reciprocating mechanism

The Model DH 22PH adopts a spiral drive system (i.e., mechanism using a reciprocating bearing),

resulting in a more compact design with the armature shaft arranged in parallel with the tool shaft. Figure

3 shows the structure of the piston reciprocating mechanism.

Armature rotation is transmitted to the second shaft via the first gear. Rotation of the second shaft is then

transmitted through a spline on the second shaft to the clutch, which engages with a reciprocating

bearing, causing the bearing to rotate. However, circular grooves on the inner race of the reciprocating

bearing are positioned at an angle of inclination relative to the second shaft. The rotation of the inner

race and shaft causes the angle of inclination to change regularly in the forward and backward directions

with respect to the second shaft, and produces a rocking motion in the outer race of the reciprocating

bearing. Finally, a rod extending from the outer race of the reciprocating bearing is connected to the

piston by a piston pin, causing the piston reciprocating motion.

REFERENCE MATERIALS

Содержание DH 22PH

Страница 21: ... 18 Fig 12 x Dust collector B structure ...