--- 25 ---

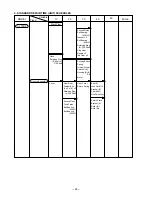

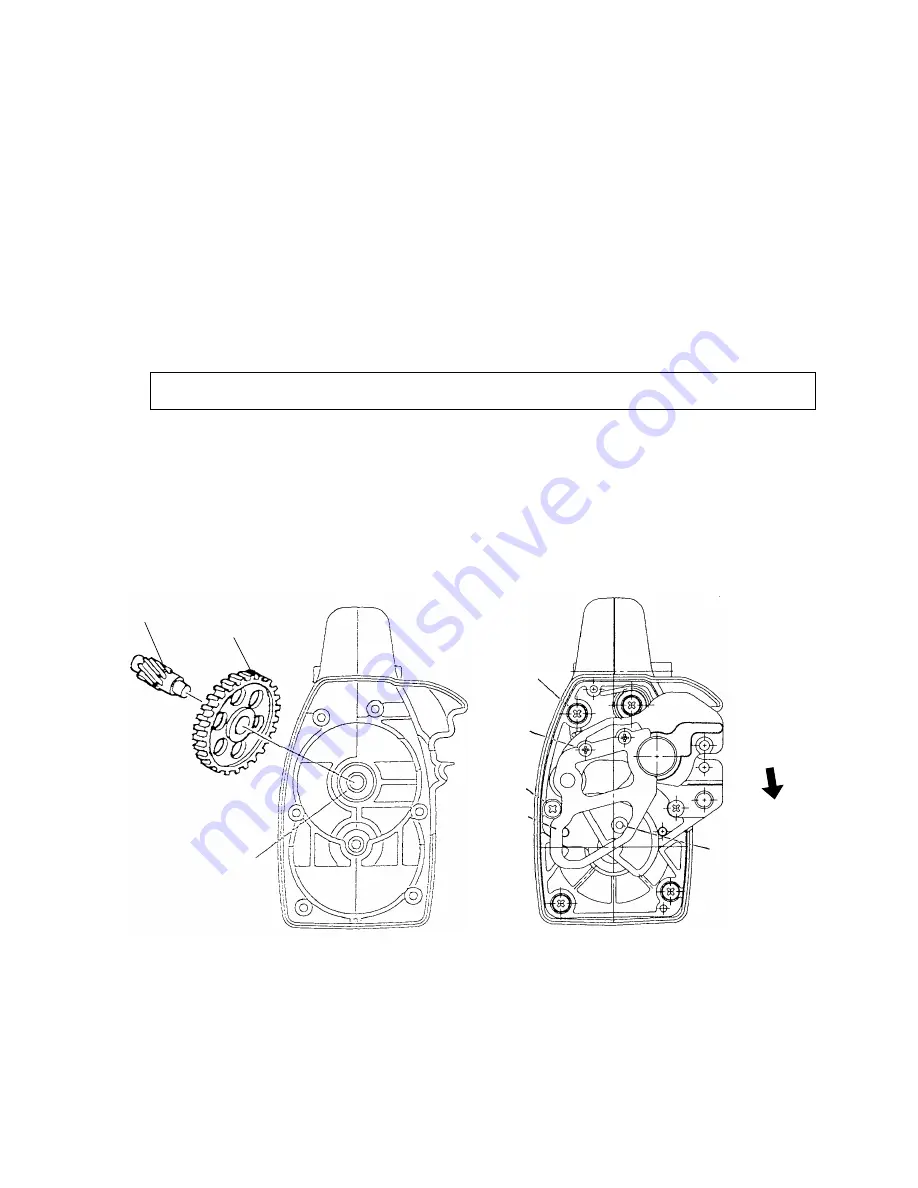

(f) Mounting the assembly to the main body

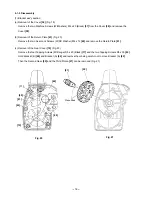

(i) Insert the Ball Bearing 608VVC2PS2L [23] in the ball bearing chamber of Housing (A) [2] (Fig. 40).

(ii) Press-fit the Third Pinion [21] in the Second Gear [22] and insert it in the Ball Bearing 608VVC2PS2L [23] of

Housing (A) [2] (Fig. 40). At this time, apply grease (Nippeco SEP-3A) to the outer circumference of the

Second Gear [22].

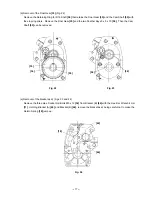

(iii) Mount the Gear Cover [19] to the housing keeping Bracket (A) [42] at the maximum cutting position in the

same manner as the removal procedure (be careful of the spring force) (Fig. 41).

(iv) Tighten the four Tapping Screws (W/Flange) D5 x 25 (Black) [17] and the two Tapping Screws D5 x 35 [43]

(Fig. 41).

CAUTION: Check that there is no scratch, dust or chips on the surfaces of the cam and the roller.

(g) Reassembly of the Return Plate [41]

Align the Return Plate [41] with the Roller Pin [54] and Bolt (A) [39]. Insert the pin of the Cam Shaft [55] in

the hole of the Return Plate [41] and secure them with the two Seal Lock Screws (W/SP. Washer) M4 x 12

[40] (Fig. 41).

Maximum

cutting

position

Fig. 40

Fig. 41

[21]

[22]

[23]

[17]

[41]

[40]

[43]

Содержание CL 10D2

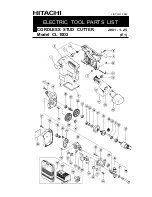

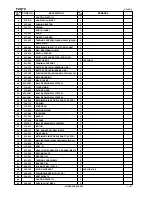

Страница 32: ...ELECTRIC TOOL PARTS LIST LIST NO CORDLESS STUD CUTTER Model CL 10D2 2001 1 25 E1 F842 ...

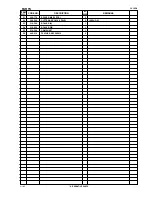

Страница 36: ......