System 2000 AUTO TEMP

8

for an alternating crop. Then when you return to the original crop you could simply

restore the level you had saved. This will reprogram the stages back to the original

settings. Note: Saving a level completely erases the level which was previously saved for

that number, so be sure before you save. The system has accommodations for two levels.

6.2.6.

Calibrating the Temperature Sensors

In any Given installation it is usually necessary to calibrate at least one of the seven

sensors. With a program located in the Program Features the Auto Temp makes this an

easy task. All that is needed to calibrate sensors is a stable building with no fans or

heaters running, and a trusted thermometer. Use the thermometer to check temperature

at the sensor locations. Then use the Select feature arrow keys to find Calibrate Sensors.

Answer Yes and the controller will ask for new temperature for Sensor 1, use the change

setting arrows to enter the correct temperature, then answer in the same manner for

Sensor 2, and so on.

6.2.7.

Artificial Light

The Auto Temp Controller has a way to control artificial lighting based on a 24 hour

time clock. There is a connection in the controller labeled "Artificial Light", in and out.

An external relay or contactor must be used to control the lighting as the relay in the

Auto Temp is not heavy enough. When programming this feature, the operator is

prompted for

Number of Cycles

(up to two),

Time on

and

Time off.

The operator can use

up to two different light cycles in every day.

6.2.8.

Feed Control

This feature can be used for feeders, or any other device that needs to run on a timed

basis. Feed Control allows you to set up the device to operate up to Four times a day.

The controller will prompt you for number of cycles (up to two), then begin cycle time,

and end cycle time for each. When Feed Control is used, it will use Stage 11, and Stage

12 for operation.

6.2.9.

Viewing All Sensors

It is possible to view all 7 sensors on 2 separate screens with the System 2000. To see

the temperatures sensed by the sensors, go into programming features, and continue

until you see a screen with S-1... S-2... and so on. This screen, and the next shows the

actual sensor readings. This allows you to detect a problem with your setup, or the

sensor itself. The temperatures shown will update every 4 seconds while they are being

displayed.

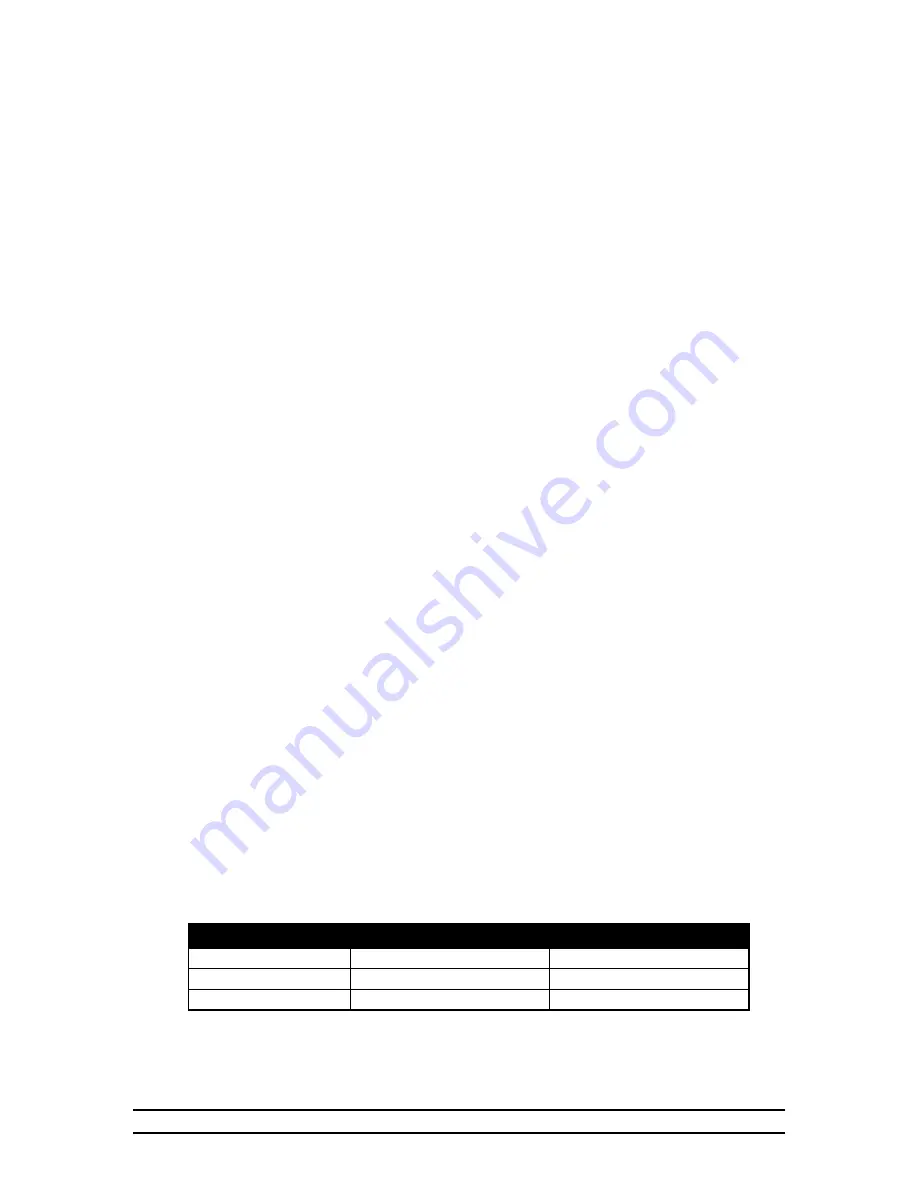

Recommended Wire Gauge for LOW VOLTAGE hookup.

Component

HHI Wiring Part No. Recommended Wire

Sensor

1502-2427

18/2 Shielded Cable

Hall Effect Devices

1502-2427

18/2 Shielded Cable

PVR-H

1503-1508

18/3 Cable SJT