REPLACING THE SQUEEGEE BODY RUBBER BLADES

Ensuring the good condition of the squeegee body rubber blades guarantees better floor cleaning and

drying results, as well as a longer service life for the vacuum motor. To replace the squeegee body

rubber blades, proceed as follows:

1. Take the machine to the maintenance area.

2. Make sure the machine is in a safe condition (see “

MACHINE SAFETY MEASURES

”).

CAUTION

: these operations must be carried out using protective gloves to avoid any possible

contact with the edges or tips of metal objects.

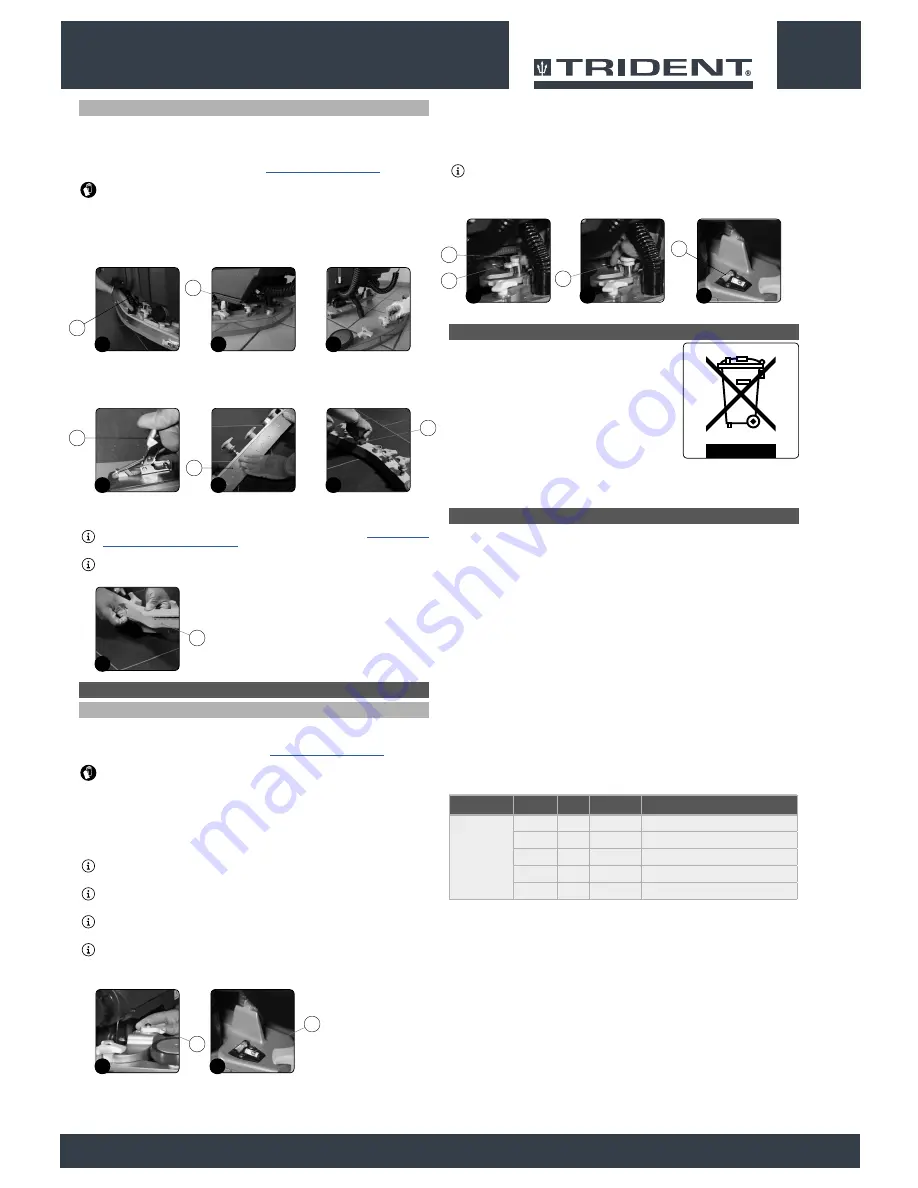

3. Remove the vacuum tube (1) from the vacuum nozzle on the squeegee body (

Fig.1

).

4. Completely unscrew the knobs (2) in the squeegee body pre-assembly (

Fig.2

).

5. Remove the squeegee body from the slits in the squeegee connector (

Fig.3

).

6. Remove the rear rubber-pressing blade by releasing the retainer (3) on the back of the squeegee

(

Fig.4

).

7. Remove the rear rubber blade (4) from the squeegee body (

Fig.5

).

8. Completely unscrew the knobs (5) in the squeegee body pre-assembly (

Fig.6

).

9. Remove the front rubber blade (7) from the inside of the squeegee (

Fig.7

).

10. Repeat the operations in reverse order to reassemble all the parts.

NB

: before using the machine, remember to adjust the squeegee body (see

“

ADJUSTING THE

SQUEEGEE BODY RUBBER BLADES

”

).

NB

: you are advised to replace both squeegee body blades in order to ensure good results when

drying the floor.

ADJUSTMENT INTERVENTIONS

ADJUSTING THE SQUEEGEE BODY RUBBER BLADES

Careful adjustment of the squeegee body rubber blades guarantees better cleaning of the floor.

To adjust the squeegee body blades, proceed as follows:

1. Make sure the machine is in a safe condition (see “

MACHINE SAFETY MEASURES

”).

ATTENTION

: these operations must be carried out using protective gloves to avoid any

possible contact with the edges or tips of metal objects.

2. Stand at the back of the machine.

Adjusting the height of the squeegee body:

3.

Adjust the height of the rubber blade in relation to the floor by loosening or tightening the knobs

(1) (

Fig.1

).

NB

: Figure 1 indicates the rotation direction for decreasing the distance between the squeegee

support and the floor. This distance can be increased by turning it in the opposite direction.

NB

: by decreasing the distance between the squeegee support and the floor, the rubber blades

present in the squeegee body move closer to the floor.

NB

: the right-hand and left-hand knobs must be rotated the same number of times, so that the

squeegee is parallel to the floor when it is working.

NB

: make sure the adjustment is correct by looking at the instrument (2) on the squeegee body

(

Fig.2

).

Adjusting the tilt of the squeegee body:

4.

Loosen the retainer knob (3) of the squeegee tilt adjustment knob (4) (

Fig.3

).

5.

To adjust the tilt of the squeegee body rubber blades in relation to the floor, tighten or loosen the

knob (5) (

Fig.4

) until the blades are bent outwards by about 30° in relation to the floor, in an even

manner along their entire length.

NB

: make sure the adjustment is correct by looking at the instrument (6) on the squeegee body

(

Fig.5

).

6.

Once the adjustment has been completed, tighten the retainer knob (3).

CHOOSING AND USING THE BRUSHES

POLYPROPYLENE BRUSH (PPL)

Used on all types of floors. Good resistance to wear and tear, and hot water (no greater than 50°C.).

The polypropylene is non-hygroscopic and therefore retains its characteristics even when working in

wet conditions.

ABRASIVE BRUSH

The bristles of this type of brush are charged with highly aggressive abrasives. It is used to clean very

dirty floors. To avoid floor damage, work only with the pressure strictly necessary.

THICKNESS OF THE BRISTLES

Thicker bristles are more rigid and are therefore used on smooth floors or floors with small joints.

On uneven floors or those with deep joints, it is advisable to use softer bristles which can enter the

gaps more easily.

Remember that when the bristles are worn and therefore too short, they will become rigid and are no

longer able to penetrate and clean deep down. In this case, like with over-large bristles, the brush

tends to jump.

PAD HOLDER

The pad holder is recommended for cleaning shiny surfaces.

There are two types of pad holder:

1.

The traditional pad holder is fitted with a series of anchor points that allow the abrasive floor pad to

be held and dragged while working.

2. The CENTRE LOCK type pad holder not only has anchor points, but also a snap-type central

locking system in plastic that allows the abrasive floor pad to be perfectly centred and held without

any risk of it becoming detached. This type of pad holder is recommended above all for machines

with more than one brush, where the centring of the abrasive discs is difficult.

25

2

3

1

1

2

5

6

4

3

4

5

7

6

2

1

1

2

4

3

5

3

4

4

5

DISPOSAL

To dispose of the machine, take it to a demolition centre or an

authorised collection centre. Before scrapping the machine,

it is necessary to remove and separate out the following

materials, then send them to the appropriate collection centres

in accordance with the environmental hygiene regulations

currently in force:

• Brushes

• Felt

• Electric and electronic parts*

• Batteries

• Plastic parts (tanks and handlebars)

• Metal parts (levers and frame)

(*) In particular, contact your distributor when scrapping electric

and electronic parts.

MACHINE

CODE

QTY

BRISTLE

NOTES

TRIDENT

T26SC PLUS

422189

2

PPL 0.3

BLUE BRUSH

422971

2

PPL 0.6

WHITE BRUSH

422972

2

PPL 0.9

BLACK BRUSH

422981

2

ABRASIVE

BRUSH

422973

2

PAD HOLDER WITH CENTRE LOCK

Содержание TRIDENT T26 SC PLUS

Страница 2: ......

Страница 27: ......

Страница 28: ...HILLYARD INDUSTRIES PO Box 909 St Joseph Missouri 64502 0909 U S A Telephone 816 233 1321 www hillyard com ...