HOW TO UNPACK THE MACHINE

The machine is shipped in specific packaging. To remove it, proceed as follows:

1.

Place the lower part of the outer packaging in contact with the floor.

NB

: use the pictograms printed on the box as a reference.

2. Remove the outer package.

WARNING

: the machine is contained in specific packaging materials, whose elements (plastic

bags, staples, etc.) can pose potential hazards, and must not be left within reach of children,

disabled persons, etc.

3. Remove the boxes containing the disc brushes and squeegee body from the machine.

CAUTION

: these operations must be carried out using protective gloves to avoid any possible

contact with the edges or tips of metal objects.

4. Insert a ramp in the rear part of the machine.

ATTENTION

: the ramp gradient must not be such as to cause damage to the machine as it

comes down.

5.

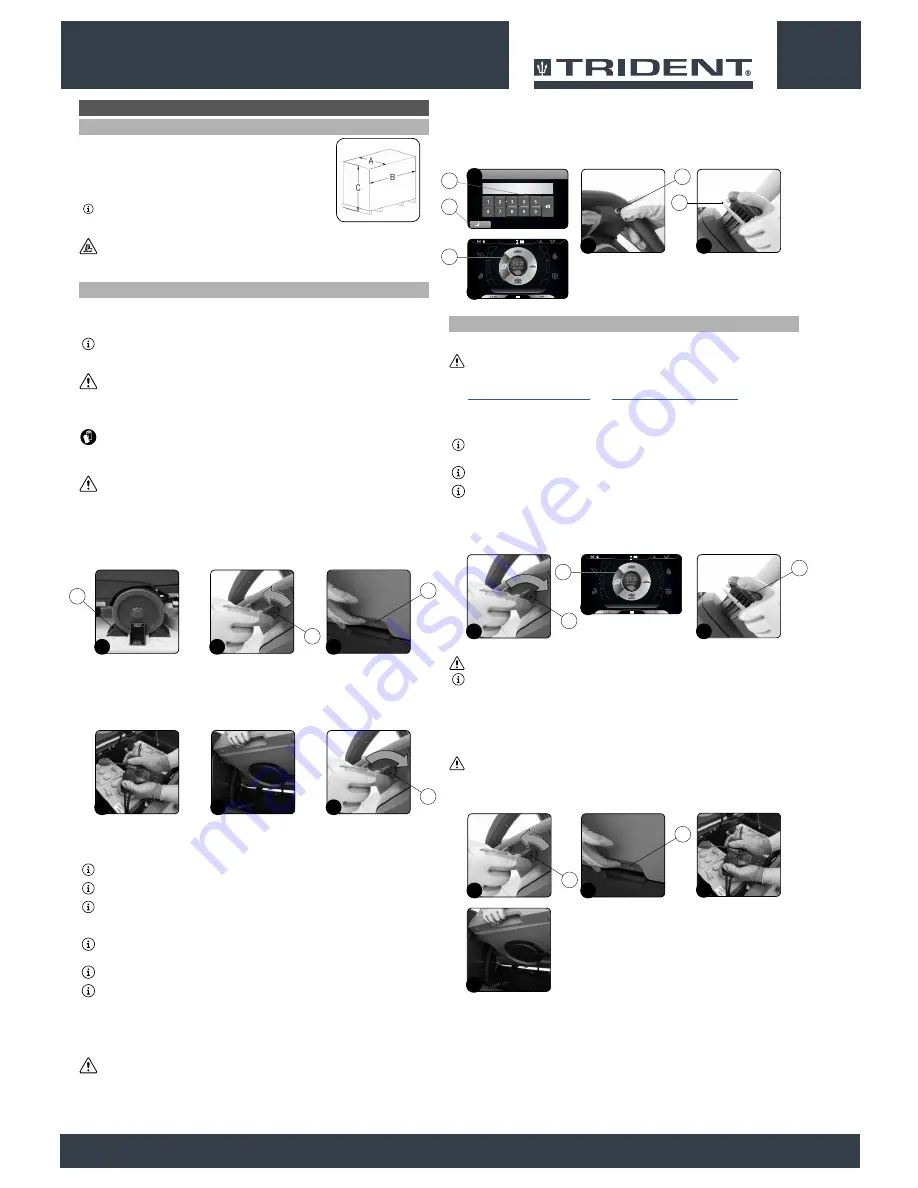

The machine is fixed to the pallet with wedges (1) that block the wheels (

Fig.1

). Remove these

wedges.

6. Check the main switch on the control panel is set to “0”. If this is not the case, turn the key (2) to

the left (

Fig.2

). Remove the key from the main switch.

7. Grip the handle (3) and raise the recovery tank to the maintenance position (

Fig.3

).

8. Connect the backup battery carriage connector to the main machine system connector (

Fig.4

).

9. Grip the handle (3) and lower the recovery tank to its working position (

Fig.5

).

10. Insert the key (1) in the main switch on the control panel. Set the main switch to "I" by making a

quarter turn of the key to the right (

Fig.6

).

11. A few seconds after ignition, the password screen is displayed (

Fig. 7

).

12. Enter the password and press the Enter key (4) (

Fig. 7

).

NB

: if you make a mistake, press Delete (5) (

Fig.7

).

NB

: it is possible to disable the password entry. Contact your nearest assistance centre.

NB

: the password entered by the manufacturer is 0000.

13. By default, the machine is set to the transfer program (6) (

Fig. 8

).

NB

: in transfer mode, both the brush head and the squeegee support are in the idle position

(raised from the pallet).

NB

: on the DS selector, the symbol of the transport program (6) is green (

Fig.8

).

NB

: the grey symbols show working programs that are not active. the green symbols show

working programs that are active.

14. Press the “REVERSE ACTIVATION - DEACTIVATION” button (7) (

Fig.9

) to engage the reverse

gear.

15. When you push the dead man's lever (8) (

Fig.10

), the machine will begin to move.

16. Drive the machine down the ramp.

ATTENTION

: during this operation, check there are no people or objects near the machine.

17. Set the main switch to “0”, turning the key (1) to the left (

Fig. 2

). Remove the key from the main

switch.

18. Grip the handle (2) and raise the recovery tank to the maintenance position (

Fig.3

).

19. Disconnect the backup battery carriage connector from the main machine system connector

(

Fig.4

).

20. Grip the handle (4) and lower the recovery tank to its working position (

Fig.5

).

HOW TO MOVE THE MACHINE

To transport the machine safely, proceed as follows:

DANGER

: before starting any task, make sure the current regulations concerning the safe

transport of dangerous substances are scrupulously observed.

1. Check the solution tank and recovery tank are empty. If they aren't, empty them (see

“

EMPTYING THE SOLUTION TANK

” and “

EMPTYING THE RECOVERY TANK

”).

2. Insert the key (1) in the main switch on the control panel. Set the main switch to “I” by turning the

key (1) to the right (

Fig.1

).

3. Using the DS selector on the control display (

Fig.2

), select the “transfer” program (2).

NB

: with this working program, both the brush head and the squeegee support are in the idle

position (raised from the floor).

NB

: on the DS selector, the symbol of the transport program (2) is green (

Fig.2

).

NB

: the grey symbols show working programs that are not active. the green symbols show

working programs that are active.

4. When you push the dead man's lever (3) (

Fig.3

), the machine will begin to move.

5. Use a ramp to move the machine up onto the transport vehicle.

CAUTION

: during this operation, check there are no people or objects near the machine.

NB

: the ramp gradient must not be such as to cause damage to the machine as it goes up.

6. Once the machine is on the means of transport, set the main switch to “0” by turning the key (1)

to the left (

Fig. 4

). Remove the key from the main switch.

7.

Get off the machine.

8. Grip the handle (4) and raise the recovery tank to the maintenance position (

Fig.5

).

9. Disconnect the battery connector from the main machine system connector (

Fig.6

).

10. Grip the handle (4) and lower the recovery tank to its working position (

Fig.7

).

WARNING

: secure the device according to the directives in force in the country of use, so that it

cannot slide or tip over.

13

MACHINE PREPARATION

HANDLING THE PACKAGED MACHINE

The machine is contained in specific packaging, and since the

packaging elements (plastic bags, staples, etc.) are a potential source

of danger, they should not be left within the reach of children, disabled

persons, etc.

The overall machine weight including packaging is 000 lb.

The overall dimensions of the package are: A=30in B=57.5in C=50in.

ATTENTION

: it is recommended that all the packaging

components be kept for any future transportation of the

appliance.

ATTENTION

: move the packaged product with handling

equipment that complies with legal requirements regarding size

and mass of the packaging.

5

4

6

2

2

1

3

1

2

3

4

5

4

5

1

4

Enter

Inserire codice

DRIVE

0000.00

100%

7

8

10

9

4

6

5

7

8

1

DRIVE

0000.00

100%

2

3

1

2

3

Содержание TRIDENT T26 SC PLUS

Страница 2: ......

Страница 27: ......

Страница 28: ...HILLYARD INDUSTRIES PO Box 909 St Joseph Missouri 64502 0909 U S A Telephone 816 233 1321 www hillyard com ...