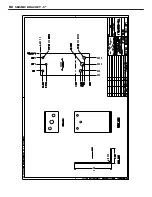

ATTENTION ELECTRICIAN

:FOR SAFETY AND CODE COMPLIANCE GROUND FIXTURE

AT TIME OF

INSTALLATION

:CAUTION

RISK OF ELECTRIC SHOCK. MORE THAN ONE POWER-SUPPLY. DISCONNECT ALL POWER-SUPPLIES BEFORE SERVICING.

P901598E - R4

BLACK

WHITE

BLUE

RED

YELLOW

PURPLE

ORANGE

WIRE IDENTIFICATION

DEFROST HEATERS (1-PHASE) DEFROST HEATERS (3-PHASE)

ANTI-CONDENSATE HEATERS

AISLE WARMER DRAIN HEATER PRIMARY FANS

SECONDARY FANS

AMBIENT FANS

LIGHTS BELL

TEMPERATURE CONTROL

DEFROST TERMINATION CONTROL

DEFROST SAFETY CUT-OUT CONTROL

LIQUID LINE SOLENOID SUCTION LINE SOLENOID

CASE/CONTROLLER POWER

TRANSFORMER

CAPACITOR RECEPTACLE

SYSTEM NEUTRAL (3-PHASE)

POWER CORD (SELF-CONTAINED) SERVICE LIGHT (HI-PRESSURE)

HIGH PRESSURE SWITCH DUAL PRESSURE SWITCH CONDENSING UNIT POWER CONDENSING UNIT FAN

1,2 L1

L3

L2

13

14 16

15

18

17

10

9

36

37

4

3

40

5

6

7

8 12

11

60,62

19,20

22

21

23

28

27

29

31

30

39

38

41

42 24

25

34

35

33

32

N

58

57

53,54

49,50

51,52

47

48

45

46

44 220V

IG RECEPTACLE GFI RECEPTACLE

HUMIDIFIER

26

43

56

55

70

71

GREEN

REFRIGERATED PAN SOLENOID

REFRIGERATED PAN BYPASS SOLENOID

AIR HEATER DEFROST SOLENOID

AIR DEFROST FAN

MAIN SECONDARY FLUID SOLENOID

SECONDARY COOLANT PUMP

GROUND TO EXTERIOR/FRAME

GROUND TO INTERIOR LINER

GROUND TO JUNCTION BOX

75

77 79

81 83 85

64

65

66

67

68

69

72

73

74

59

76

61

65 220V

73 220V

GROUND TO LIGHTS

97

67 220V 69 220V

TANK FLUSH SOLENOID

MISTING SOLENOID DRIP DOWN TIMER

REAR STORAGE BOX FANS

87 220V 89 220V

94

90

88

86

87 89

95

WIRE ID

WIRING IDENTIFICATION

B1

Содержание 3NDML-NRG

Страница 16: ...BLUE WHITE BLACK 3NDML WIRING DIAGRAM B2 ...

Страница 19: ...SEISMIC BRACKET 5 D2 ...

Страница 20: ...SEISMIC BRACKET 7 D3 ...

Страница 21: ...SEISMIC BRACKET 11 D4 ...

Страница 22: ...SEISMIC BRACKET 15 D5 ...