FLOOR PREP

1.

Ask the general contractor if your current copy of the

building dimensions are the most recently issued.

Also, ask for the points of reference from which you

should take dimensions to locate the cases.

2.

Using chalk lines or a laser transit, mark the floor

where the cases are to be located for the entire lineup.

The lines should coincide with the outside edges of the

case feet.

3.

Leveling is necessary to ensure proper case alignment

and to avoid potential case damage. Locate the high-

est point on the positioning lines as a reference for

determining the proper height of the shim-pack level-

ers. A laser transit is recommended for precision and

requires just one person.

4.

Locate basehorse positions along the chalk line. Spot

properly leveled shim packs at each basehorse loca-

tion.

LINE-UP & INSTALLATION

Single Case

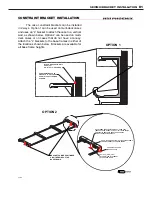

1.

Roll the case into position, leaving a minimum of 2"

between the back of the case and the wall. Using a

“J” bar, raise the end of the case (under cross sup-

port), remove the caster assembly (Fig. 1), and lower

the basehorse on to the shim packs. Repeat on the

other end of the case.

2.

Once the basehorse is properly placed on the shim

packs, check the vertical plumb of the case by plac-

ing a bubble level on the rear wall. Add/remove shim

packs as needed. For the horizontal level, repeat this

process after placing the bubble level on the front sill.

Multi-Case

1.

Remove the shelves (discard the shelf clips) and any

loose items from the cases that may interfere with case

joining (e.g. shipping braces, mirror assemblies, etc).

Keep all loose items as they will be used later in

the installation process.

2.

Remove the return air grill at the case joint. The grill

lifts out without fasteners and may be easily removed

to gain clear access to the case-to-case joining bolts.

3.

Follow the single-case installation instructions for the

first case, then position the next case in the line-up ap-

proximately 3’ away. Remove the casters on the end

that is closest to the first case.

4.

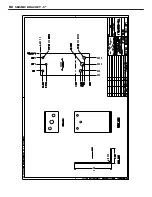

Apply the foam tape gasket (supplied) and a bead of

butyl or silicone sealant to the end of the first case (Fig.

2). From the opposite end, push the second case to

a position that is approximately 6" from the first case,

then remove the remaining casters and position case

on the shim packs.

= bolt holes

X = foam tape gasket

O = butyl or silicone sealant

NOTE: It is recommended that cases

be bolted together in the numbered

order indicated in the diagram.

XXX

XXX

XXX

XXX

XXX

XXX

XXX

XXX

XXX

XXX

XXX

XXX

XXX

XXX

XXX

XXX

XXX

XXX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

X

XXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXX XX

XX

XX

XX

XX

XX

OO

OO

OO

OO

OO

OO

OO

OO

OO

OO

OO

OO

OO

OO

OO

OO

OO

OO

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

OOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOO

O

O

O

O

O

OO

OO

OO

OO

OO

OO

OO

OO

OO

OO

OO

OO

OO

OO

OO

OO

OO

OO

OO

OO

OOO

O

OOO

OO

O

O

OOO

O

OOO

OO

O

O

1

3

5

4

Fig. 2 Bolt holes, foam tape gasket and sealant

2

CASE INSTALLATION

CAUTION!

Be certain that your hands and feet are

out of the way before lowering the case

after the removal of the casters. Failure

to do so may result in serious injury.

Fig. 1 Removing the casters is an easy process. Simply flatten and

remove the cotter pins that are holding the casters in place. Then

lift the case with a “J” bar and slide the caster assemblies out. The

dismantled casters can now be discarded.

COTTER

PIN

CASTER

3

Содержание 3NDML-NRG

Страница 16: ...BLUE WHITE BLACK 3NDML WIRING DIAGRAM B2 ...

Страница 19: ...SEISMIC BRACKET 5 D2 ...

Страница 20: ...SEISMIC BRACKET 7 D3 ...

Страница 21: ...SEISMIC BRACKET 11 D4 ...

Страница 22: ...SEISMIC BRACKET 15 D5 ...