Important: Always read and follow the operating instructions.

• 9

Installation Instructions

Proper unit installation is necessary for safe

use and efficient operation. Proper installa-

tion also helps protect the unit from dam-

age and makes service easier. Always place

safety poster and instructions near the unit.

Location

Select a location that provides the operator with

enough space to use the equipment in a safe manner.

The area selected should be well lit, easy to clean and

should be away from oil, grease, brake lathe chips, etc.

Avoid areas where bystanders and customers may be

present.

Floor Mounting

The machine should be securely bolted to the floor

with suitable anchors using the hole at each corner of

the machine base.

Assembly Instructions

Please inspect this unit for damage/missing parts

prior to use.

Carton Contents (boxes marked 1 through 3):

Contains the base, tower and table top for your RC-

50M Manual tire changer. Be sure to check all contents

prior to assembly.

(Optional) Carton Contents (box marked 4):

Contains the Bead Loosener. Be sure to check all con-

tents prior to assembly.

Base Assembly:

Enclosed with base unit you will

find 4 (four) anchor bolts (1/2” X 3”) choose the loca-

tion for the base at this time being sure to position the

RC-50M in a clear working area. (It is suggested that

the unit is firmly mounted to the floor prior to attaching

the tower or table top.) Attach the tool tray to the base

with supplied hardware.

Tower Assembly:

Using the supplied hardware 4

(four) (12mm X 55mm hex bolts) that attaches the

tower to the base of the RC-50M, position the tower in

place. Attach the swing arm to the tower, (at this time

it is suggested that grease be added to the pivot shaft.)

The slider may be put into place at this time, (add the

return spring prior to placing the slider in the swing-

arm guide) once placed attach the bead head. Check

travel, clearances and locking mechanism prior to use.

Table Top Installation:

Prior to installation BE SURE

TO PLACE THE TABLE TOP WITH THE LOCKING KNOB

FACING FORWARD FOR ACCESS WHEN RC-50M IS

IN USE. Once the table top has been positioned check

all clearances for complete 360-degree rotation. Place

wheel jaws at desired position, making sure to place

holding pin completely through the guild hole prior to

locking the wheel in place.

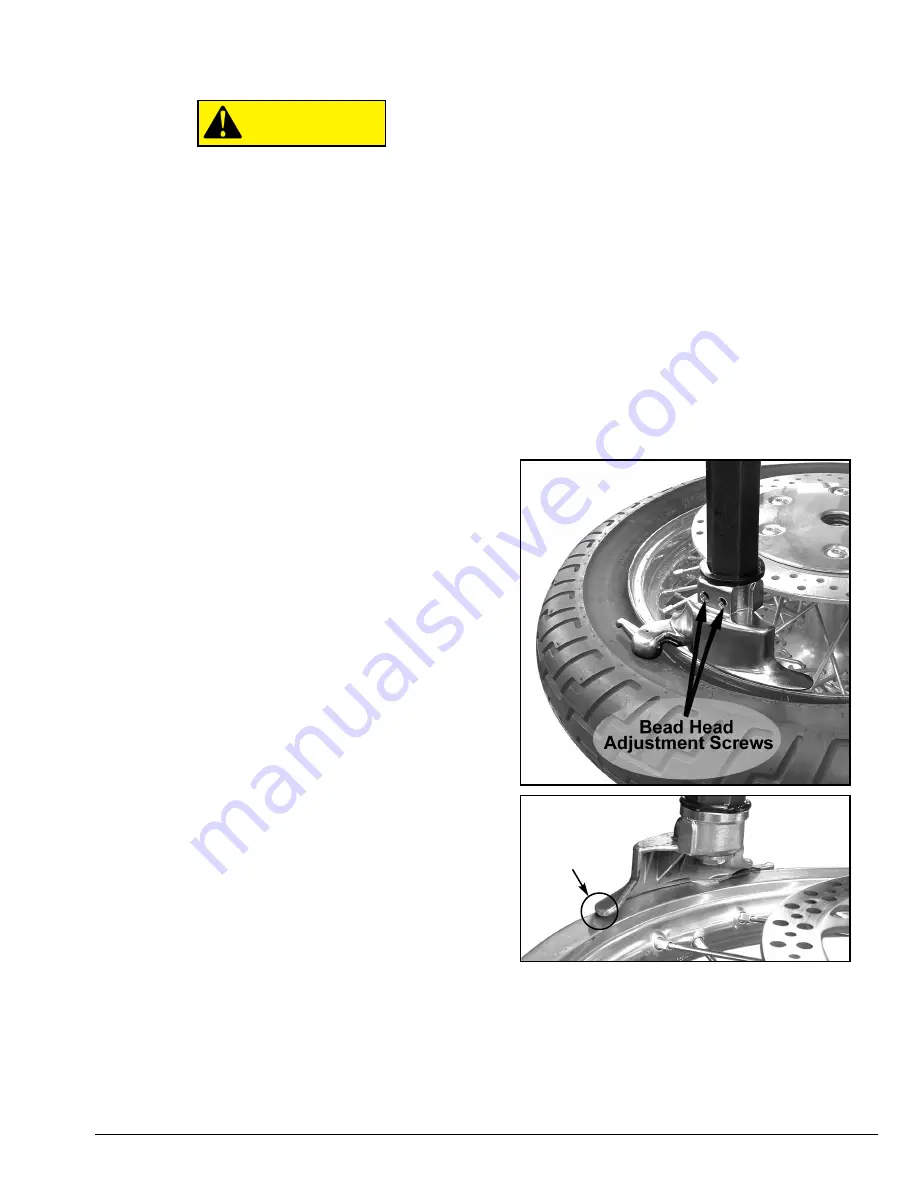

Bead-head Adjustment:

Prior to using your RC-50M

you should take a few moments to check the align-

ment of the bead-head. This is a simple procedure that

will require a 4.5mm hex wrench and an 18-inch wheel.

Set the jaws in place to accept the 18-inch wheel

(using a bare wheel will ease the adjustment process),

tighten the jaws so that the wheel is held in place.

Lower the bead head until contact is made between

the plastic rim protector and top outer edge of the

wheel. If they do not match-up, make the following

adjustment using the two adjusting screws (located

side-by-side on the bead-head mounting base, fig.1) If

needed, rotate the head until contact is made with the

wheel. The plastic protector should be touching the

wheel as close to the center as possible. The rear por-

tion of the bead head should overlap the outer edge of

the wheel so that there is approximately 1-3mm over-

hang (fig. 2.) Offset changes are made with the two

adjusting screws.

Assembly for (Optional) Bead Loosener:

Check all

contains prior to assembly. Attach support to the base

using the supplied hardware. At this point you may

now attach the link, breaker and lever arm to the sup-

port. The Bead Loosener will attach to the RC-50M by

hooking on to the locating mount.

CAUTION

Fig 1.

Fig 2.

1-3mm

overhang