31

5.3

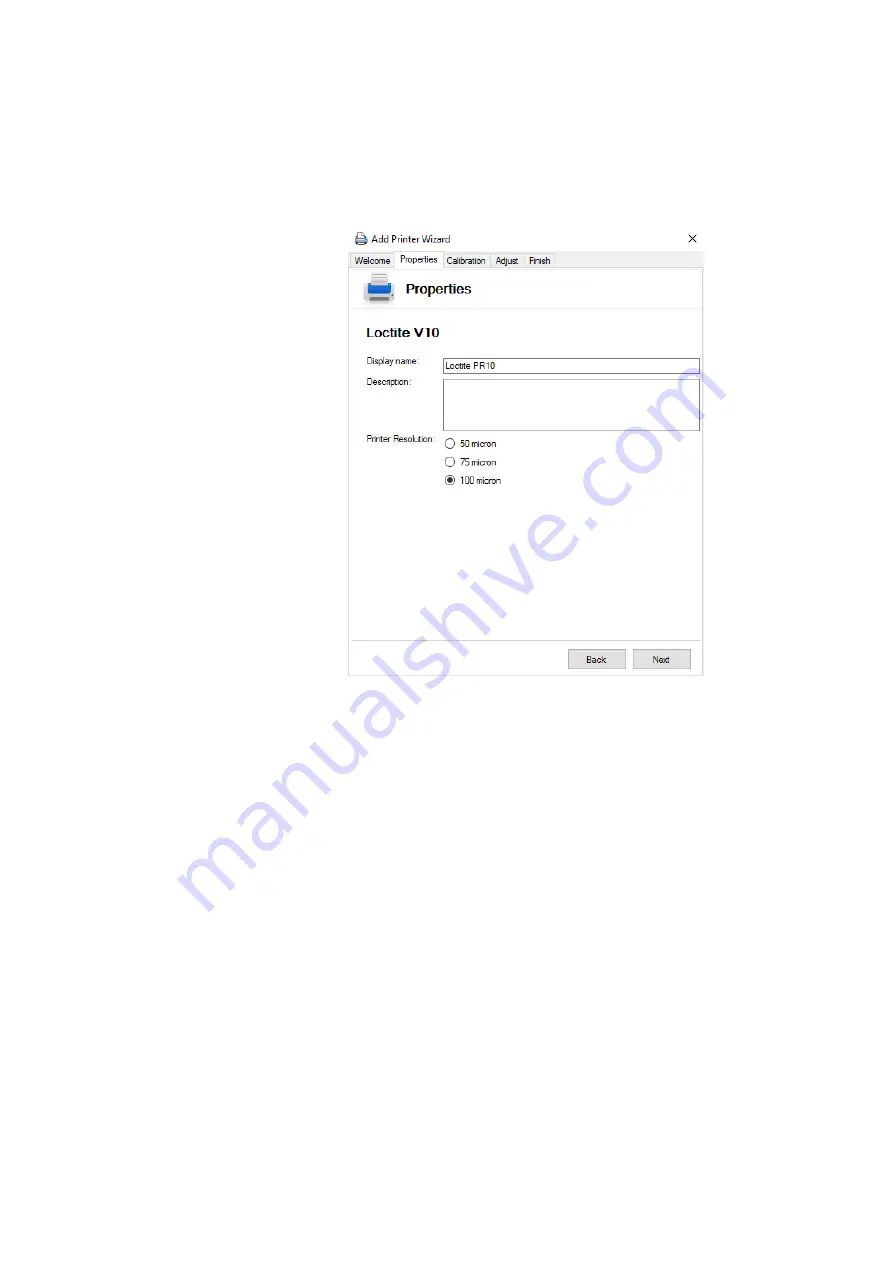

Adding a Printer to the Loctite Operator Station PC Software

Before creating a print job, the new printer needs to be added to the software.

To do this follow the below instructions:

1.

Open Loctite Operator Station Software

2.

Select

Tools

>

Managers

>

Printer Manager

>

Add

3.

Follow the instructions on the

Printer Connection Wizard.

Set the printer resolution to

100 micron

.

4.

Select ‘

next’

and follow the calibration instructions in section 6

Содержание Loctite EQ PR10.1 DLP

Страница 1: ...Loctite EQ PR10 1 DLP 3D Printer Operating Manual IDH 2416987 ...

Страница 8: ...8 3 3 Machine Connections 21 Power Connector 22 Ethernet Connector 21 22 ...

Страница 11: ...11 The job can be deleted by swiping left on the Planned Jobs screen To begin printing press the Start button ...

Страница 40: ...40 ...