17730-299

55

Component Replacement

ULTIMAAX

®

for Fire and Rescue Vehicles

2 .

Straddle Mount Bar Pin Bushing

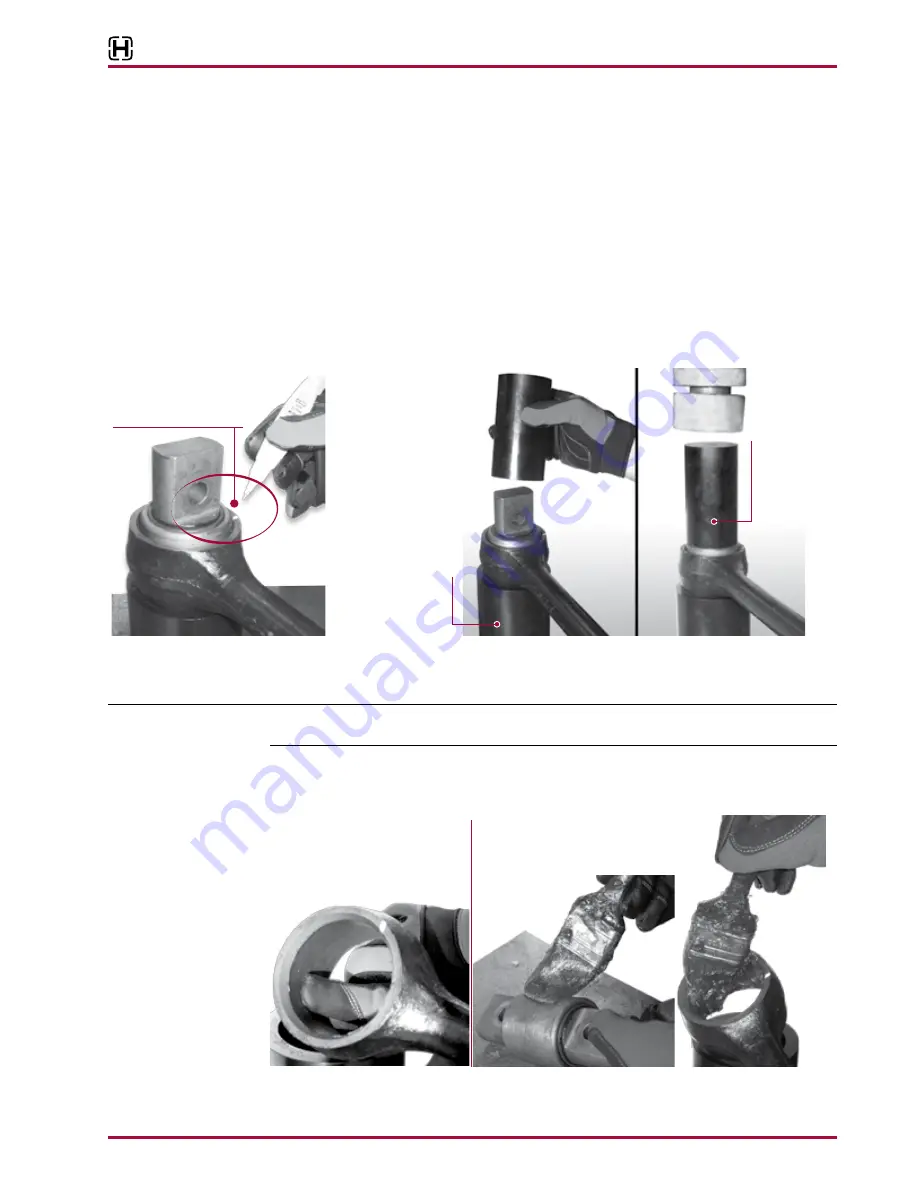

—When servicing a straddle mount bar pin bushing assem-

bly, mark the clocking position of the straddle mount bar pin flats with a paint stick on the

torque rod end hub prior to disassembly, see Figure 8-55 . This marking will serve as a guide

when installing the new bushing so the original clocking position can be retained .

3 .

Taper Pin Bushing

— Remove the fastener and the concave washer from the taper pin

bushing .

4 . Support the torque rod end hub and centered on the receiving tool (for a tapered bushing,

have the tapered stud pointing down) . Ensure the torque rod is squarely supported on the

press bed for safe ty .

5 . Install the removal tool, see Figure 8-56 .

6 . Press directly on the removal tool until the bushing clears the torque rod end hub, see

Figure 8-57 .

FIGURE 8-55

FIGURE 8-56

FIGURE 8-57

BUSHING INSTALLATION

1 . Clean and inspect the inner diameter of the torque rod end hubs, see Figure 8-58 .

SERVICE HINT

DO NOT

use a paraffinic oil, or soap base lubricant . Such lubricants can cause adverse reactions

with the bushing, causing premature failure .

2 . Lubricate the inner diameter of the torque rod end hubs and the outer metal of new bushings

with NLGI #2 EP grease, see Figure 8-59 .

FIGURE 8-58

FIGURE 8-59

Torque Rod

Bushing

Receiving Tool

Torque Rod

Bushing

Installation /

Removal Tool

Mark the clocking position of the

bar pin flats with a paint stick

on the torque rod end hub

Apply NLGI #2-EP (Extreme Pressure)

lubricant to the inner diameter of torque

rod end hub and bushings

Inspect and clean the inner

diameter of torque rod

end hubs