17730-299

45

Component Replacement

ULTIMAAX

®

for Fire and Rescue Vehicles

INSPECTION

After removing the bar pin end bushings, thoroughly inspect the beam bores . If the equalizing

beam is damaged from end bushing removal, replacement of the equalizing beam is required,

replace with a new equalizing beam .

DO NOT

attempt re-bush or use an equalizing beam that

has been damaged .

FAILURE TO REPLACE AN EQUALIZING BEAM THAT HAS BEEN DAMAGED FROM BUSHING REMOVAL

CAN RESULT IN THE FAILURE OF THAT BEAM, ADVERSE VEHICLE HANDLING AND POSSIBLE PERSONAL

INJURY OR PROPERTY DAMAGE .

1 . Clean the bores of the equalizing beams with emery cloth or ball hone, removing any nicks or

metal buildup from bushing removal .

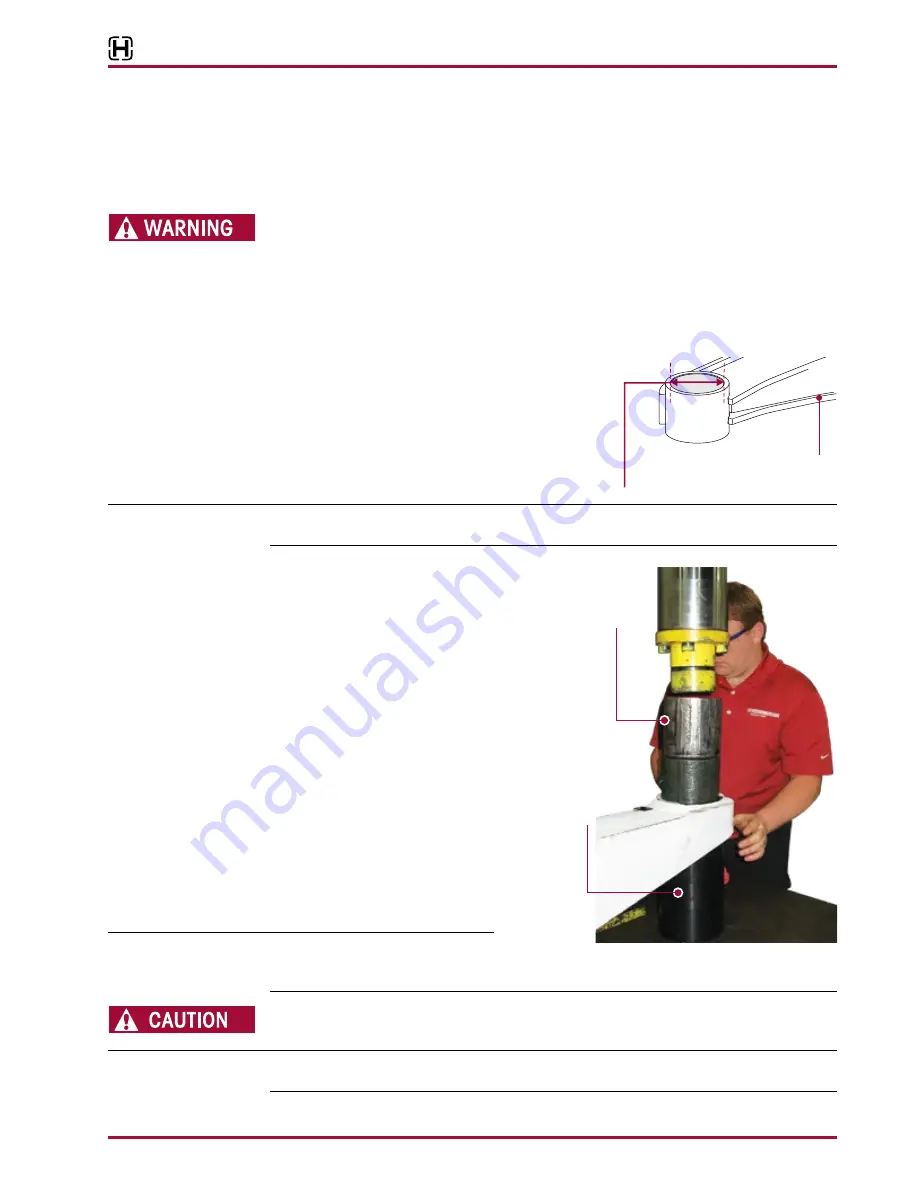

FIGURE 8-30

2 . Measure the equalizing beam end hub bore inner

diameter . The Hendrickson specification for the equal-

izing beam end hub bore diameter is 4 .621" ± 0 .004"

(117 .38 mm ± 0 .10 mm), and is taken as the mean

of any two readings 90° apart in the same plane, see

Figure 8-30 . If it is

NOT

within the specified range,

replacement is required .

ASSEMBLY

NOTE

Always use the bushing outer metal for pressing operations . Pressing on the bushings inner metal

may damage the bushing and require bushing replacement .

FIGURE 8-31

1 . The equalizing beam bore may

have a more substantial lead in

chamfer at one end of the bore

than the other . Take advantage of

the larger chamfer by pressing in

the new end bushing from this end .

2 . Lubricate the equalizing beam

end hub inside bore and the bar

pin end bushing outer sleeve with

a NLGI #2 – EP (Extreme Pressure)

grease .

3 . Place the equalizing beam in

a shop press with the end hub,

squarely supported on the receiv-

ing tool, see Figure 8-31 .

4 . Position and align the end bush-

ing to the mark made before

removal as shown in Figure 8-29 .

NOTE

The end bushing must be square with

the equalizing beam end hub before pressing the end bushing into the beam . End bushings

pressed in at an angle will damage the end bushing and the equalizing beam .

CARE MUST BE TAKEN DURING THE INSTALLATION OF THE BUSHING . DO NOT PUSH ON THE INNER

METAL OF THE BUSHING, DOING SO WILL CAUSE DAMAGE TO THE BUSHING AND VOID WARRANTY .

NOTE

Always use the bushing outer metal for pressing operations . Pressing on the bushings inner metal

may damage the bushing and require bushing replacement .

5 . Place the end bushing installation tool on the end hub .

Equalizing

Beam

4.617" / 4.625"

(117.28 mm / 117.48 mm)

Equalizing Beam

End Hub Bore Diameter

Equalizing

Beam

End Bushing

Installation Tool

Part No.

66086-106

End Bushing

Receiving Tool

Part No.

66086-111