23

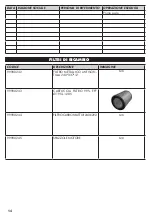

MOST FREQUENT PROBLEMS: CAUSES AND REMEDIES

Given that most of the malfunctions occur for improper use of the system, are indicated in the table below

some possible malfunctions that may occur, and the measures to be taken to remedy them.

FAULT TYPE

CAUSES

ACTION

The cleaner suddenly stops Power outage

Restore the power supply

The fuse is burned

Change

Motor is burned

Repair or change

The yield of the mechanical

cleaner is decreased

Filters are dirty

Repair or change

Fumes are escaping

Wrong installation of the filters

Check the closures of the panels and seals

Bad smell

Activated carbons filter full

Change

RISKS AND EMERGENCIES

RISKS

DESCRIPTION HAZARDS AND SPECIFIC PROTECTIONS

The manufacturer must in any case put in place actions in order to reduce the dangers that can arise due

to incorrect use of the machine by installing on the machine itself the protection devices.

Description hazards cannot be eliminated by the security measures adopted

The dangers cannot be eliminated by the security measures taken by the manufacturer if they are caused

by incorrect use of the machine or by a failure on the part of the user of the safety instructions in this

manual (refer to the above concerning the things do not do).

As already mentioned above we recommend the use of gloves and mask during cleaning and filter change,

in order to avoid any possible consequence to the operator.

EMERGENCY SITUATIONS

In case of fire:

• Use powder comply with standards

• Pay attention to the combustion gases (polyester filters and plastic electrical plant)

The materials and substances used in the construction of the equipment does not pose a risk of explosion

IMPORTANT NOTE

THE EQUIPMENT SHOULD NOT BE USED IN EXPLOSIVE ATMOSPHERE

MAINTENANCE

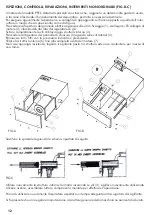

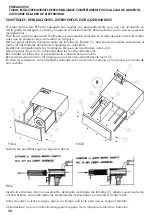

PFE – CLEANING AND CHANGE OF PARTS (FIG.A)

To easily maintain the PFE, it is recommended to place it on the opposite side of the circuit breaker so

that it is positioned as shown.

Using the side screws (1), open the closing panel (2), remove the anti-spark filter (3) and wash it with an

air jet in the opposite direction to the suction flow or replace it if it is too dirty. Replace it in the seat by

inserting it into the appropriate guides.

Unscrew the locking knob (4) of the cartridge (5) and then pull it out. Wash it with a jet of air in the

opposite direction to the suction flow or, if it is too dirty, replace it. Then, carefully place it back in its seat

by tightening the clamp knob (4) down.

From the air outlet side, you can find the carbon filter panel (6), remove it and replace it with a new one.

Make sure all filters are positioned correctly, then place the locking panel (2) and fasten all the screws

that hold it in position (1).

ATTENTION:

All these operations must be done absolutely while the socket is disconnected from power supply.