14

Fresh Air Boxes – ALB EC

Installation and Operating Instructions

The generally applicable safety at work and accident prevention regulations must be observed!

– Electrical work must only be carried out by an authorised electrician.

– Use appropriate lifting equipment and fastening devices to dismantle the fan, Observe transport sketch!

– Dispose of the fan components according to the valid rules and laws.

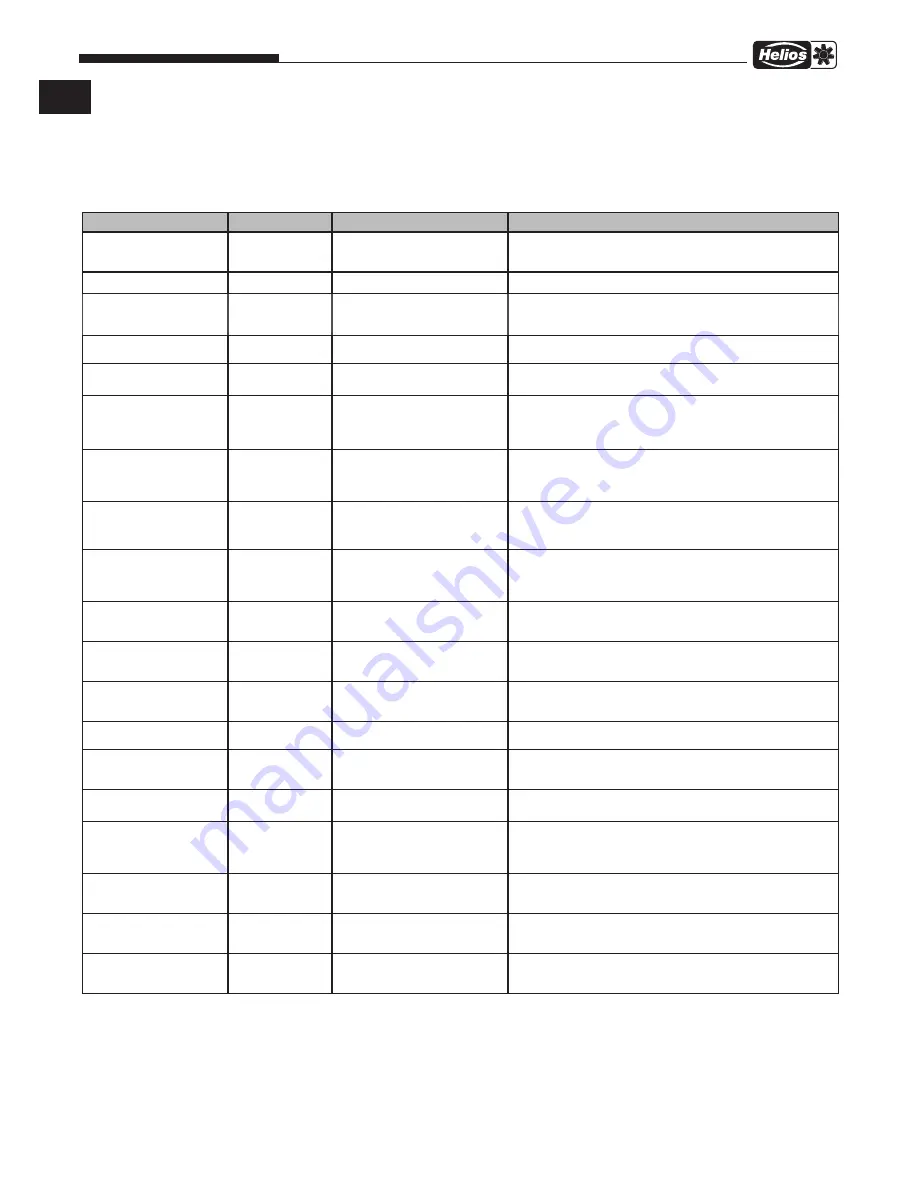

7 .5 Error description

Error

Unit behaviour

Problem

Solution

4 - Supply air fan error

Unit does not function. Fan overheating or damage to the ther-

mal contacts of the supply air fan.

Determine cause of motor overheating (e.g. faulty bearing, mechanical prob-

lem, short circuit, ...). The motor must be replaced, if necessary.

6 - Supply air filter blo-

cked

Unit ventilates.

Filter blocked.

Check condition of filter and replace filter, if necessary.

8 - Failure of pre-hea-

ter 1

Unit ventilates.

Pre-heater overheating.

Check whether the air can flow freely through the unit and the electric

pre-heater has sufficiently cooled down. Check the activation of the safety

temperature limiter.

9 - Heater battery 1 error

Unit ventilates.

Heater battery overheating or damage

to temperature sensor.

Check whether the air can flow through the unit freely.

12 - CO2 sensor error

Unit ventilates.

Malfunction of air quality sensor.

Check whether the CO2 sensor is connected correctly. Check function of

the CO2 sensor, if necessary (output signal value).

16 - Supply air -

Damage to external

temperature sensor

(T-EXT1)

Unit does not fun-

ction.

Temperature sensor error.

Check whether the sensor is correctly connected to the electronics. Carry

out a function test with the sensor by means of resistance measurement, if

necessary (the resistance value at +20 °C is around 10 k

Ω

).

17 - Supply air -

Defective temperature

sensor after heater bat-

tery (T-EXT2)

Unit does not function. Temperature sensor error.

Check whether the sensor is correctly connected to the electronics. Carry

out a function test with the sensor by means of resistance measurement, if

necessary (the resistance value at +20 °C is around 10 k

Ω

).

18 - Supply air -

Defective temperature in

supply air duct (T-EXT3)

Unit does not fun-

ction.

Temperature sensor error.

Check whether the sensor is correctly connected to the electronics. Carry

out a function test with the sensor by means of resistance measurement,

if necessary (the resistance value at +20 °C is around 10 k

Ω

).

24 - Error concerning

water return temperature

sensor

(T_WATER_OUT)

Unit does not function. Temperature sensor error.

Check whether the sensor is correctly connected to the electronics. Carry

out a function test with the sensor by means of resistance measurement, if

necessary (the resistance value at +20 °C is around 10 k

Ω

).

25 - Error concerning

room temperature sensor

(T_Room)

Unit ventilates.

Temperature sensor error.

Check whether the sensor is correctly connected to the electronics. Carry

out a function test with the sensor by means of resistance measurement, if

necessary (the resistance value at +20 °C is around 10 k

Ω

).

27 - Error concerning

supply air filter pressure

sensor

Unit ventilates.

Pressure sensor error.

Check whether the measuring device is damaged or contaminated. Check

whether the pressure hoses are not blocked. Replace the pressure sensor,

if necessary.

28 - Error concerning

supply air fan pressure

sensor

Unit does not function. Pressure sensor error.

Check whether the measuring device is damaged or contaminated. Check

whether the pressure hoses are not blocked. Replace the pressure sensor,

if necessary.

32 - Error concerning air

quality sensor

Unit ventilates.

Malfunction of air quality sensor.

Check whether the air quality sensor is connected correctly. Check function

of the sensor, if necessary (output signal value).

34 - Error concerning ex-

ternal temperature sensor

from BMS

Unit ventilates.

Sensor error at BMS or incorrect data

Check address and sensor value in BMS system. Check function of BMS

sensor.

50 - Supply air filter blo-

cked > 80 %

Unit ventilates.

Filter blocked.

Replace filter.

70 - Water heater battery

frost protection

Unit ventilates.

Water heater battery frost protection

is active.

Automatic protection of water heater battery is active to prevent damage at

low temperatures. This function ends automatically as soon as the return

temperature has reached the target value.

71 - Water heater - Wait

for the water temperature

Unit ventilates.

Water temperature assessment active. Process ends automatically.

72 - Water heater - Wait

for the supply air tempe-

rature

Unit ventilates.

Supply air temperature assessment.

Process ends automatically.

74 - Flow rate reduction,

minimum temperature in

duct not reached

Unit functions in limi-

ted mode.

The unit attempts to reach the mini-

mum temperature.

Supply air temperature is not reached. There is an automatic power correc-

tion (supply air fan is adjusted down).

EN

Содержание ALB EC 30/20 EH

Страница 23: ...21 Außenluft Boxen ALB EC Montage und Betriebsvorschrift DE ...

Страница 45: ...21 Fresh Air Boxes ALB EC Installation and Operating Instructions EN ...

Страница 46: ...22 Fresh Air Boxes ALB EC Installation and Operating Instructions ...

Страница 47: ...23 Fresh Air Boxes ALB EC Installation and Operating Instructions ...