Positioning the Crane

After the crane has been properly adjusted, it can be moved in to position to secure the intended load. The crane

must be able to freely roll into position and all potential obstacles must be carefully negotiated or moved. When posi-

tioning the crane, always consider the way in which the load will be secured to the crane. The crane’s chain, or other

adequate load capturing device that meets or exceeds the capacity of the crane in its given position, must be located

directly over the intended load before attempting to secure the load. It is important to the safety of the crane operator

and other personnel that the path of the crane is carefully planned, both before and after securing the load.

WARNING:

Contacting any obstacle, including overhead obstacles, with the crane can make the crane jump or

shift which can cause the load to swing or rotate dangerously and may lead to property damage, serious per-

sonal injury, and/or death.

Securing the Load

Once the shop crane has been positioned, the load must be secured utilizing an adequate capturing device, such as

a load leveler, chain, or sling, capable of sustaining the load. The load must be secured by using attachment points

that are adequate for holding the weight of the load and allow the load to be lifted without shifting or rotating. Ensure

that the hook and chain assembly or other adequate load capturing device is directly above the load to be raised.

Pay careful attention to how the load will react when raised. If the center of gravity of the load is not directly under the

crane’s capturing device, or the load is awkwardly captured, the load and crane may swing or rotate dangerously.

WARNING:

Ensure that the load is properly secured before attempting to lift or move it. If the load is improperly

secured it can unexpectedly fall, swing, or rotate dangerously which may lead to property damage, serious per-

sonal injury, and/or death.

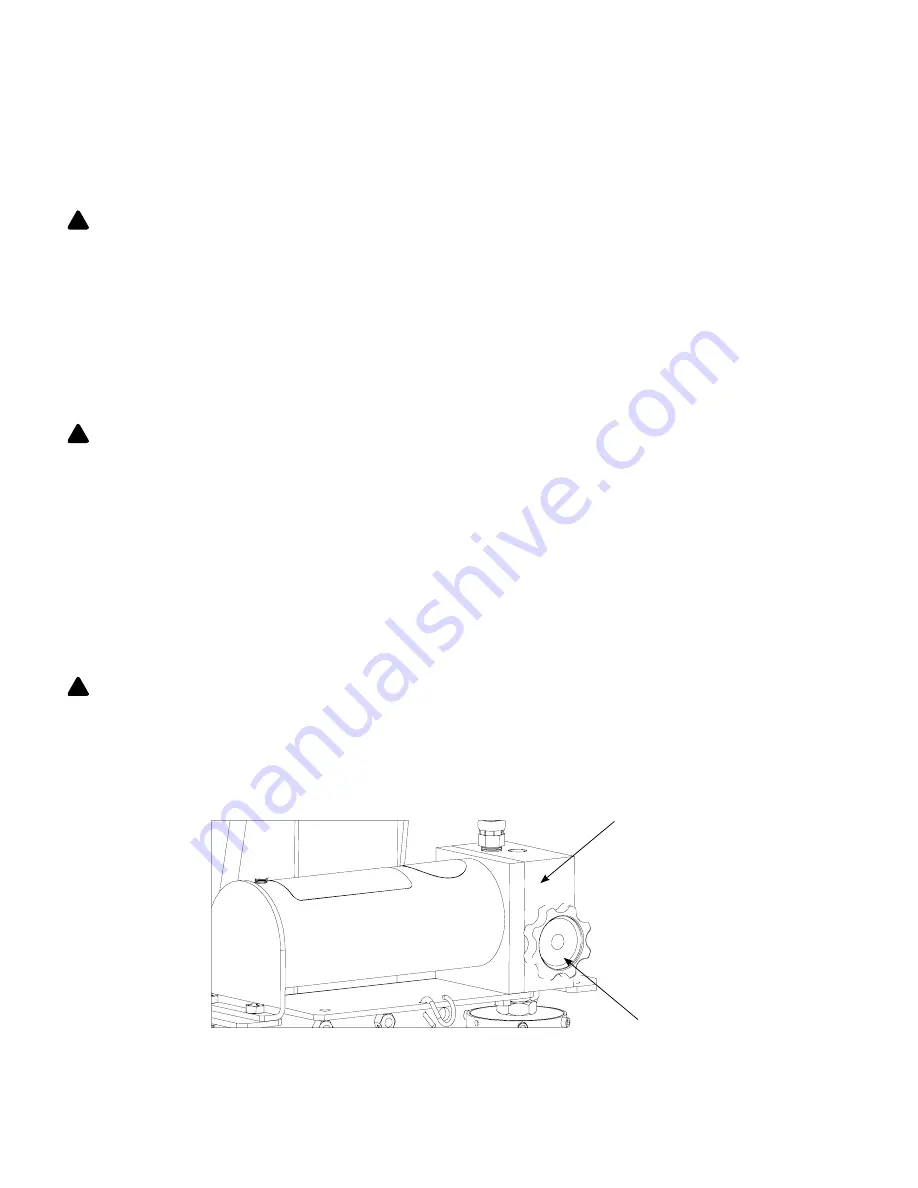

Adjusting the Load Height

The hydraulic pump is used to adjust the height of the load.

1. To raise the load, the release knob on the pump must be closed by turning the knob clockwise until it is finger tight.

2. The pump can then be actuated by working the handle on the manual pump or activating the air valve on the air

hydraulic pump, depending on which type of pump is installed.

3. While the pump is actuated, the cylinder will extend raising the boom and load.

4. To lower the load, the release knob must be opened by SLOWLY turning the knob counter-clockwise. This will lead

to retraction of the cylinder and lowering of the load.

5. Once the load is at the desired height, the release knob must be closed in order to keep the load at that height.

WARNING:

Lowering or stopping the load too quickly can cause the load to swing or rotate dangerously and

may result in property damage, serious personal injury, and/or death. This crane is not intended for overhead

lifting. Do not allow the crane’s load or boom to be above any body part. If the load were to fall, it would cause

serious personal injury or death.

Figure 15

Hydraulic Pump

Release Knob

!

!

!

9