40

Rev. 05/2020

41

Rev. 05/2020

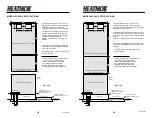

Firebox Door Hoses and Elbows

Principle of the Door Hoses

The door hoses allow HTF to circulate between the

firebox door and the water jacket.

Operation of the Door Hoses

The door hoses allow HTF from the water jacket to

pass through the firebox door, through thermal

siphoning. Refer to “Firebox Door”

Maintenance / Result

Maintaining the door hoses and elbows ensures that

HTF is able to flow through the door. Build-up (calcium)

in the elbows is possible over time, which slowly reduces the HTF

flow through the door. If HTF does not flow freely through the

hoses to the firebox door, you may hear popping sounds in the

door. Once the hoses are around five years old or if they show

signs of wear, they should be replaced. Replacement of hoses or

cleaning of the elbows is always easier if the HTF is cool rather

than hot. To clean the elbows, remove the hoses and use a pipe

cleaning brush to clear out the build-up.

Removal and Replacement Door Hoses

NOTE:

Top Door Hose is 20in, bottom Door Hose is 18in

1) Turn off power to the air combustion blowers.

2) Ensure that the fire in the firebox is extinguished, which will allow the HTF to cool.

3) With hose clamps or vice-grips, pinch the door hoses in the middle of the hose.

4) Before removing the old door hose, cut the new pieces of door hose, one at 18

inches and the other at 20 inches.

These measurements are critical.

5) Pinch the new door hose in the middle of the

hose, creating a tight seal.

6) Loosen the hose clamps on each end of the

door hose.

7) Remove the first end of the door hose needing

replacement.

8) Push on the end of the new door hose and

repeat the steps for the opposite end of the hose.

9) Tighten the hose clamps, securely fastening the

door hose to the nipple on the furnace or firebox door.

10) Remove the vice-grips pinching the door hoses. This will allow HTF to flow through.

11) Check for leaks.

12) Repeat the steps to change additional door hoses.

ABSOLUTELY NO FIRE IN THE FIREBOX WHEN PERFORMING THIS PROCESS.

DO NOT PERFORM THIS PROCESS WHEN UNIT HTF TEMPERATURE

IS UNSAFE. ALWAYS WEAR PROPER PERSONAL PROTECTIVE

EQUIPMENT WHEN WORKING WITH HTF AND CHEMICALS.

Door Hose

Elbow

Clamping hose

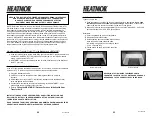

Firebox Door Handle

Principles of the Firebox Door Handle

Fastened to the firebox door, the handle provides a secure method of controlling the

opening and closing of the firebox door. By opening the firebox door, (only until the door

handle hits the second stage of the safety latch), gives a space for fresh air to enter the

firebox without the risk of a “flash back.” The firebox door handle is also designed to “stick”

to the

firebox door

handle holder

on the outer door. This procedure prevents either of the

doors closing while the Heatmor

TM

is being loaded with coal.

Maintenance / Result

To maintain the door handle, ensure the handle closes and opens fairly easily. If the handle

closes too hard, it will be hard to open and close the door. If the closure is too loose, it will

be harder to obtain a perfect seal around the door. If you do not have a firm seal, you could

potentially create an air leak resulting in further complications. Refer to “Checking for Air

Leaks” for further details or contact your local dealer. You can adjust the two bolts on the

latch for correct closure.

Removal and Replacement Door Handle

1) Turn off power to the blowers.

2) Ensure the fire in the firebox is extinguished.

3) Loosen and remove the nut on the bearing and the nut on the mounting plate.

4) Replace the handle

5) Replace and tighten the nut on the bearing and the nut on the mounting plate.

Firebox Door Handle