HAULOTTE GROUP

9 AXLE AND RELATED COMPONENTS

113

9 AXLE AND RELATED COMPONENTS

If you have a North American - ANSI aerial lift platform refer to section

9A

Dexter Axle and Related

Components.

If you have a European - CE aerial lift platform refer to section

9B

Bradley Brake Adjustment section.

9A DEXTER AXLE AND RELATED COMPONENTS

The following sections are reprinted from the Dexter Axle Operation and Maintenance Manual 2008.

SET UP AND ADJUSTMENT

For proper performance, all new axles should have the following checked at the specified intervals:

Wheel Nut Torque

: at 10, 25, and 50 miles (16, 40, and 80 Kilometers).

Brake Adjustment

: at 200 and 3,000 miles (322, and 4,828 Kilometers).

Tire Pressure

: to manufacturer’s requirements.

Brake Synchronization

: set brake controller per controller manufacturer’s directions.

GENERAL MAINTENANCE – ELECTRIC BRAKES

Drum Brake Adjustment

Most Dexter 12 1/4” electric brakes have a self adjusting feature. If manual adjusting is required, use

the following procedure:

Brakes should be adjusted (1) after the first 200 miles (322 Kilometers), of operation when the brake

shoes and drums have “seated”, (2) at 3,000 mile (4,828 Kilometers) intervals, (3) or as use and

performance requires. The brakes should be adjusted in the following manner:

1. Jack up trailer and secure on adequate capacity jack stands. Follow trailer manufacturer’s

recommendations for lifting and supporting the unit. Maker sure the wheel and drum rotates

freely.

2. Remove the adjusting hole cover from the adjusting slot on the bottom of the brake backing plate.

3. With a screwdriver or standard adjusting tool, rotate the star wheel of the adjuster assembly to

expand the brake shoes. Adjust the brake shoes out until the pressure of the linings against the

drum makes the wheel very difficult to turn.

NOTE

: For drop spindle axles, a modified adjusting tool may be necessary.

4. Then rotate the star wheel in the opposite direction until the wheel turns freely with a slight lining

drag.

5.

Replace the adjusting hole cover and lower the wheel to the ground.

6.

Repeat the above procedure on all brakes. For best results, the brakes should be set at the same

clearance.

CAUTION

DO NOT lift or support the trailer on any part of the axle or

suspension system. NEVER go under any trailer unless it

is properly supported on jack stands which have been

rated for the load. Improperly supported vehicles can fall

unexpectedly and cause serious injury or death.

Содержание 3522A

Страница 1: ...OPERATOR S MAINTENANCE MANUAL B33 01 0093 Rev 4 May 2013...

Страница 76: ...HAULOTTE GROUP 6 DECAL REPLACEMENT 76 DECAL KIT ANSI...

Страница 78: ...HAULOTTE GROUP 6 DECAL REPLACEMENT 78 IDENTIFICATION PLATES OPTIONAL EQUIPMENT ANSI...

Страница 81: ...HAULOTTE GROUP 6 DECAL REPLACEMENT 81 DECALS ANSI CONTINUED B06 00 0533 B06 00 0505 B06 00 0534 B06 00 0404...

Страница 84: ...HAULOTTE GROUP 6 DECAL REPLACEMENT 84 DECAL KIT CE...

Страница 86: ...HAULOTTE GROUP 6 DECAL REPLACEMENT 86 IDENTIFICATION PLATES OPTIONAL EQUIPMENT CE...

Страница 88: ...HAULOTTE GROUP 6 DECAL REPLACEMENT 88 DECAL KIT AU...

Страница 90: ...HAULOTTE GROUP 6 DECAL REPLACEMENT 90 IDENTIFICATION PLATES OPTIONAL EQUIPMENT AU...

Страница 92: ...HAULOTTE GROUP 6 DECAL REPLACEMENT 92...

Страница 102: ...HAULOTTE GROUP 8 MATERIAL SAFETY 102 MATERIAL SAFETY DATA SHEET LEAD ACID BATTERIES WET FILLED WITH ACID UN 2794 CONT...

Страница 103: ...HAULOTTE GROUP 8 MATERIAL SAFETY 103 MATERIAL SAFETY DATA SHEET LEAD ACID BATTERIES WET FILLED WITH ACID UN 2794 CONT...

Страница 104: ...HAULOTTE GROUP 8 MATERIAL SAFETY 104 MATERIAL SAFETY DATA SHEET LEAD ACID BATTERIES WET FILLED WITH ACID UN 2794 CONT...

Страница 105: ...HAULOTTE GROUP 8 MATERIAL SAFETY 105 MATERIAL SAFETY DATA SHEET LEAD ACID BATTERIES WET FILLED WITH ACID UN 2794 CONT...

Страница 106: ...HAULOTTE GROUP 8 MATERIAL SAFETY 106 MATERIAL SAFETY DATA SHEET POWERFLOW AW HVI HYDRAULIC OIL...

Страница 107: ...HAULOTTE GROUP 8 MATERIAL SAFETY 107 MATERIAL SAFETY DATA SHEET POWERFLOW AW HVI HYDRAULIC OIL CONTINUED...

Страница 108: ...HAULOTTE GROUP 8 MATERIAL SAFETY 108 MATERIAL SAFETY DATA SHEET POWERFLOW AW HVI HYDRAULIC OIL CONTINUED...

Страница 109: ...HAULOTTE GROUP 8 MATERIAL SAFETY 109 MATERIAL SAFETY DATA SHEET POWERFLOW AW HVI HYDRAULIC OIL CONTINUED...

Страница 110: ...HAULOTTE GROUP 8 MATERIAL SAFETY 110 MATERIAL SAFETY DATA SHEET POWERFLOW AW HVI HYDRAULIC OIL CONTINUED...

Страница 111: ...HAULOTTE GROUP 8 MATERIAL SAFETY 111 MATERIAL SAFETY DATA SHEET POWERFLOW AW HVI HYDRAULIC OIL CONTINUED...

Страница 112: ...HAULOTTE GROUP 8 MATERIAL SAFETY 112 MATERIAL SAFETY DATA SHEET POWERFLOW AW HVI HYDRAULIC OIL CONTINUED...

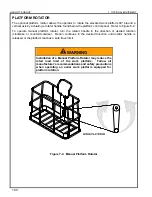

Страница 137: ...HAULOTTE GROUP 9 AXLE AND RELATED COMPONENTS 137 Figure 9 1 Standard Brake Adjustment Procedure...