17 |

P a g e

4.0 OPERATION

4.3 Refrigerant Sight Glass/

Moisture Indicator

A liquid-line sight glass/moisture indicator

has been installed to help you identify when

the system is low on refrigerant and to assist

the refrigeration mechanic when recharging

the system.

The sight glass/moisture

indicator is located at the

filter drier and is visible

when the service panel is

removed. When the

compressor is running,

bubbles flowing through

the sight glass indicate

that the Haskris system

is low on refrigerant.

Turbulence and bubbles inside the sight

glass are normal immediately after the

compressor turns on, and immediately after

it turns off. The sight glass should be clear

when the compressor is energized and

running.

4.4 Refrigerant Pressure Control

The refrigerant pressure control is a safety

device. The refrigerant pressure control de-

energizes the compressor motor when

refrigerant operating pressures are outside

the safe limits set by Haskris. The pressure

control can be found at the base of the

Haskris system.

NOTE:

Adjustments to the safe operating limits

of any refrigeration pressure control

should be made only after a qualified

refrigeration technician installs

refrigerant pressure gauges on the high

and low sides of the refrigeration system.

Low Pressure Control

All refrigerated platforms include a low

pressure control. This control, whether

single or part of a dual control, de-energizes

the refrigerant compressor when a

significant amount of refrigerant has leaked

out of the system, or when a restriction has

occurred in the refrigeration circuit. The low

pressure control also serves as an added

level of freeze-protection. The low pressure

control automatically resets when the

refrigerant pressure increases to a safe

level.

High Pressure Control

All refrigerated platforms include a high-

refrigerant pressure safety cutout with

manual

reset. The high pressure control de-

energizes the refrigerant compressor when

there is insufficient airflow through an air-

cooled condenser. The high pressure control

must be manually reset after the refrigerant

pressure decreases to a safe level.

Содержание OPC 12

Страница 7: ...4 P a g e 2 0 INSTALLATION 2 2 System Location Continued ...

Страница 8: ...5 P a g e 2 0 INSTALLATION ...

Страница 15: ...12 P a g e 2 0 INSTALLATION ...

Страница 26: ...23 P a g e 6 0 WARRANTY 5 0 MAINTENANCE ...

Страница 27: ...24 P a g e 6 0 WARRANTY 5 0 MAINTENANCE ...

Страница 28: ...25 P a g e 6 0 WARRANTY 5 0 MAINTENANCE ...

Страница 29: ...26 P a g e 6 0 WARRANTY 5 0 MAINTENANCE ...

Страница 30: ...27 P a g e 6 0 WARRANTY 5 0 MAINTENANCE ...

Страница 32: ...29 P a g e 6 0 WARRANTY 5 0 MAINTENANCE ...

Страница 33: ...30 P a g e 6 0 WARRANTY 5 0 MAINTENANCE 6 1 Standard Product Warranty 6 0 WARRANTY ...

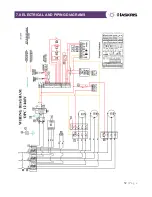

Страница 35: ...32 P a g e 6 0 WARRANTY 7 0 ELECTRICAL AND PIPING DIAGRAMS ...

Страница 36: ...33 P a g e 6 0 WARRANTY 7 0 ELECTRICAL AND PIPING DIAGRAMS ...