Debris Blower

R

R

•

Never allow hands, clothing or any

part of the body to enter the discharge

chute or near moving parts.

•

Avoid wearing loose-fitting clothing.

•

Wear approved eye and ear protection

while operating the machine.

•

The machine should be operated on

level surfaces only.

•

Before starting the machine, visually

inspect all nuts, bolts and other

fasteners to see that they are properly

secured. Nuts, bolts and other

fasteners should be checked every 8

to 10 hours of operation for proper

alignment and tightness.

Operation

•

Make certain the impeller chamber is

empty before starting the machine.

•

If a foreign object should strike the

impeller mechanism of the machine

and cause an unusual noise or

vibration, shut the engine or PTO off

immediately and allow it to come to a

complete stop. Disconnect the spark

PTO shaft from the power unit, and

then do the following:

1. Inspect for damage.

2. Repair or replace any damaged

parts.

3. Check for and tighten any loose

bolts, nuts, fasteners or parts.

•

Keep debris material from building up

in the discharge and inlet area, as this

may prohibit proper discharge of

airflow and can cause poor

performance.

•

Keep the impeller inlet area clean from

debris and other accumulations.

•

Keep all safety shields and guards in

place and in good working condition.

•

Keep your face and all body parts

away from inlet and discharge

openings.

•

Stay away from the discharge area

when machine is in operation.

•

If the Debris Blower should become

clogged, shut off the engine or PTO

and allow it to come to a complete

stop. Disconnect the spark plug wire

from the spark plug or PTO shaft

before clearing debris.

•

Do not allow hands, clothing or any

part of the body to enter the discharge

chute, impeller inlet or near any

moving parts.

•

Replace damaged or missing safety

decals.

•

Keep hands, feet and clothing away

from PTO driven parts.

•

Keep all guards and shields in place

during operation. Disengage PTO and

shut off the engine before removing

guards or shields.

•

Never attempt to adjust, clean or

lubricate the machine while it is in

operation.

•

Operator should never wear loose

clothing when working around PTO.

•

Before starting tractor, make sure that

the transmission and PTO are

disengaged.

•

Make sure the tractor’s engine is at

idle speed before engaging the PTO.

•

Be sure the tractor’s engine is at idle

before changing the airflow of the

Debris Blower Diverter.

6

Содержание Debris DB2700

Страница 1: ...Debris Blower R R R Debris Blower R 2 2012 Operator s Manual DB2700 DB3600 5 2013...

Страница 2: ...Debris Blower R R...

Страница 14: ...Debris Blower R R...

Страница 15: ...Debris Blower R R R Debris Blower R 2 2012 Operator s Manual DB2700 DB3600 Parts Section...

Страница 16: ...Debris Blower R R...

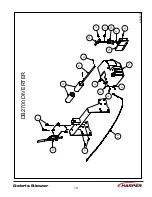

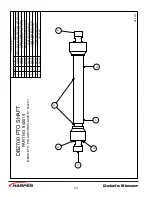

Страница 21: ...Debris Blower R R 12 9 11 8 2 3 15 7 5 14 13 4 6 6 4 7 1 16 DB2700 DIVERTER 4 16 2012 10 19...

Страница 29: ...Debris Blower R R DB3600 DIVERTER 2 17 8 18 11 12 10 9 14 1 3 13 8 6 15 16 8 5 7 4 4 18 2012 27...

Страница 35: ...Debris Blower R R NOTES...