Debris Blower

R

R

1.

Remove from crate.

2.

Mount Diverter Handle Assembly to

the frame of the machine with the two

3/8” bolts already in the frame.

3.

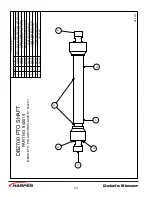

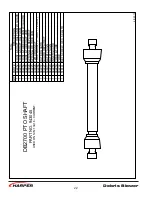

Connect PTO shaft to input shaft of

machine, tighten set screws on shaft.

4.

Mount 3-point pins on Debris Blower.

5.

Mount Debris Blower to 3-point of trac-

tor and connect PTO shaft.

Note:

A set of belts between the PTO shaft

and the impeller shaft assembly drive the

fan blades whenever the PTO drive-shaft

is turning.

On initial operation of the Debris

Blower, the

belts may shrink

and need

readjustment after the first hour of use.

When readjusting belt tension, use a

straightedge across the faces of pulleys to

make sure they are properly aligned and

the belts will run true.

SAFETY WARNING!

•

Keep pants and loose clothing away

from PTO drive and shaft and all

drive pulleys, belts and shafts.

•

Never operate the Debris Blower

beyond the suggested 540 PTO

speed.

•

Do not attempt to service machine

while it is in operation.

SAFETY WARNING!

•

Wear approved eye and ear

protection while operating the

Debris Blower.

•

Keep all guards in place during

operation. Never operate the Debris

Blower with safety shields removed.

•

Before operating the machine,

check to ensure that all belt guides

and tensioner are in place to

prevent belts from slipping off the

pulleys and systems from being

accidentally engaged.

•

Check inlet and discharge housings

for children, pets and foreign

objects before operating.

•

Keep clothing and all body parts

away from rotating parts. Do not

wear loose fitting clothing.

•

Periodically clean debris material

away from the machine to lessen

the possibility of fire. Always keep a

fire extinguisher near the Debris

Blower during operation.

•

Impeller blade rotation cannot be

controlled from the Debris Blower.

•

Obtain and wear safety glasses

when operating this machine.

Note:

A safe operator is one who practices

safety and uses good common sense to

protect himself from flying material.

Assembly

Operation

8

Содержание Debris DB2700

Страница 1: ...Debris Blower R R R Debris Blower R 2 2012 Operator s Manual DB2700 DB3600 5 2013...

Страница 2: ...Debris Blower R R...

Страница 14: ...Debris Blower R R...

Страница 15: ...Debris Blower R R R Debris Blower R 2 2012 Operator s Manual DB2700 DB3600 Parts Section...

Страница 16: ...Debris Blower R R...

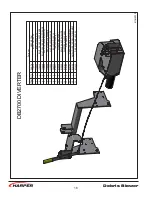

Страница 21: ...Debris Blower R R 12 9 11 8 2 3 15 7 5 14 13 4 6 6 4 7 1 16 DB2700 DIVERTER 4 16 2012 10 19...

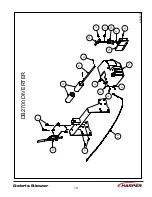

Страница 29: ...Debris Blower R R DB3600 DIVERTER 2 17 8 18 11 12 10 9 14 1 3 13 8 6 15 16 8 5 7 4 4 18 2012 27...

Страница 35: ...Debris Blower R R NOTES...