9

P43 Pellet Stove

vent Pipe

Pellet vent pipe (known as PL vent) is constructed

of two layers with air space between the layers.

This air space acts as an insulator and reduces the

outside surface temperature to allow a clearance

to combustibles of 1 to 3 inches.

Follow vent

manufacturer's guidelies and instructions.

The

sections of pipe lock together to form an air tight seal in

most cases. However, in some cases a perfect seal is

not achieved. For this reason and the fact that the P43

operates with a positive vent pressure

we specify that

the joints also be sealed with silicone.

Aluminum

tape can also be used for any joint that is 1 ft. or more

from the outlet of the stove.

We cannot emphasize enough, the importance of

sealing every seam and joint in the venting system

which is inside the home. Even the smallest pin hole

can leak and when it does you will smell wood smoke

or a creosote smell in the room. If this occurs check

for leaks. Leaks are easiest to see during start-up.

Alternatively you can use a smoke pellet to leak test

the venting before lighting your first fire.

avoiding Smoke and Odors

negative Pressure, Shut-down, and Power

Failure:

T

o reduce the probability of back-drafting or

burn-back in the pellet burning appliance during

power failure or shut-down conditions, the stove

must be able to draft naturally

without exhaust

blower operation. Negative pressure in the house will

resist this natural draft if not accounted for in the pellet

appliance installation.

Heat rises in the house and leaks out at upper levels.

This air must be replaced with cold air from outdoors,

which flows into lower levels of the house. Vents and

chimneys into basements and lower levels of the house

can become the conduit for air supply, and reverse

under these conditions.

Outside air:

harman home heating and hearth & home tech-

nologies strongly recommend attaching outside

air in all installations, especially lower level and

main floor locations.

venting

iMPOrtant nOtice

Approved Pellet Vent Pipe, Such As Type "PL",

Must Be Used.

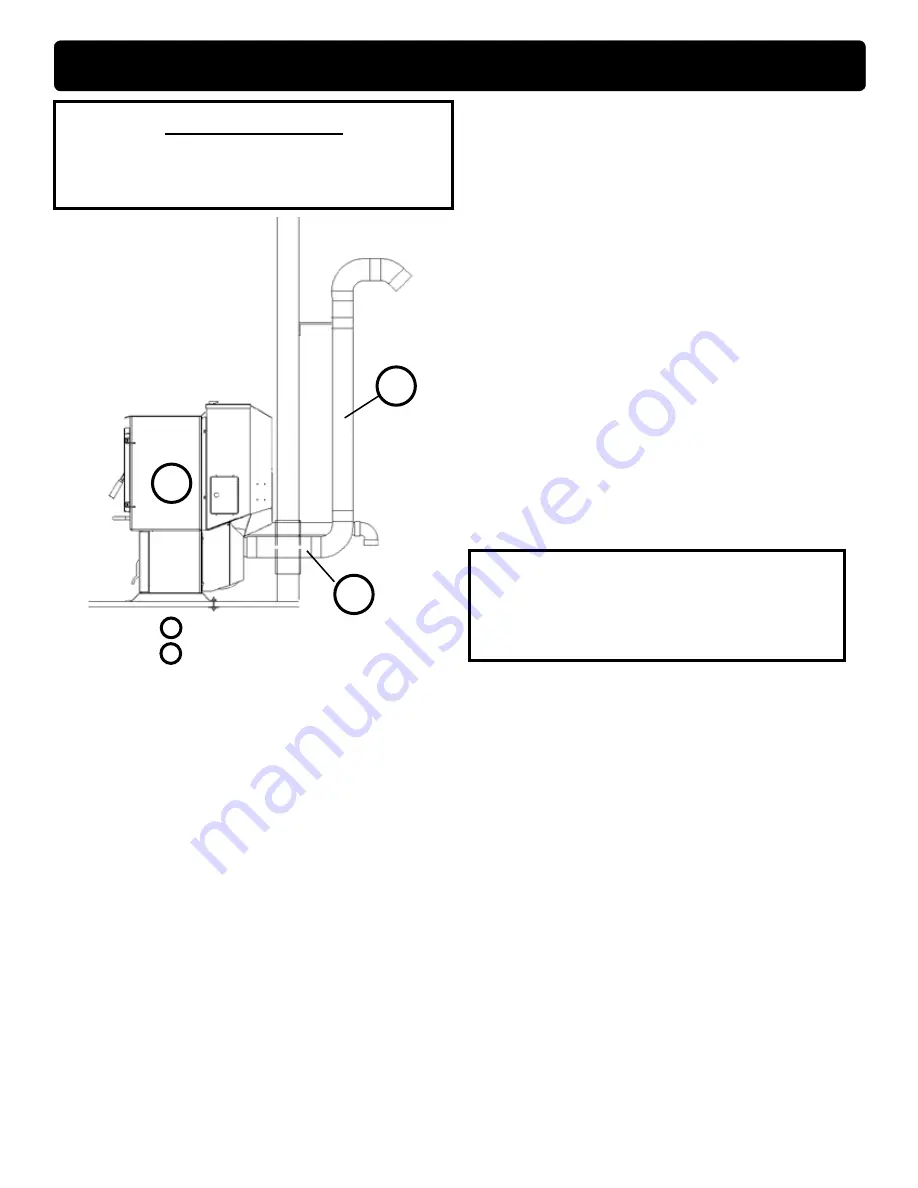

= Positive Static Pressure

= Negative Static Pressure

+

+

-

+

-

Fig. 7

venting

A combustion blower is used to extract the

combustion gases from the firebox. This causes

a negative pressure in the firebox and a positive

pressure in the venting system as shown in Fig. 7.

The longer the vent pipe and more elbows used in

the system, the greater the flow resistance. Because

of these facts we recommend using as few elbows

as possible and 15 feet or less of vent pipe. The

maximum horizontal run should not exceed 48".

If more than 15 feet of pipe is needed, the interior

diameter should be increased from 3" to 4" because

a larger pipe causes less flow resistance.

be sure

to use approved pellet vent pipe wall and ceiling

pass-through fittings to go through combustible

walls and ceilings.

The use of a starting collar is

not always necessary. The first piece of pipe must

be fastened securely with at least 2 fasteners to the

flue collar of the stove. The two screws provided

are a self-drilling style, however, due to material

thickness, drilling a 3/32" pilot hole is recommended.

a chiMneY MuSt be OF a tYPe

Suitable FOr SOlid Fuel.

chiMneY and cOnnectOr MuSt be

Maintained in gOOd cOnditiOn and

KePt clean.

Содержание P43

Страница 2: ......

Страница 39: ...39 P43 Pellet Stove Service Maintenance Log Date Of Service Performed By Description Of Service...

Страница 40: ...Proudly Printed On 100 Recycled Paper...