Page 10

For technical questions, please call 1-888-866-5797.

Item 58005

SA

FE

TY

OP

ERA

TI

O

N

MAINT

ENANC

E

SE

TUP

Maintenance and Servicing

Procedures not specifically explained in this manual must

be performed only by a qualified technician.

TO PREVENT SERIOUS INJURY FROM ACCIDENTAL OPERATION:

Make sure that the Trigger is in the off-position, unplug the tool from its electrical outlet,

and allow it to cool completely before performing any procedure in this section.

TO PREVENT SERIOUS INJURY FROM TOOL FAILURE:

Do not use damaged equipment. If abnormal noise or vibration

occurs, have the problem corrected before further use.

Inspection, Maintenance, and Cleaning

1.

BEFORE EACH USE,

inspect the general

condition of the tool. Check for:

• loose hardware

• misalignment or binding of moving parts

• damaged cord/electrical wiring

• cracked or broken parts

• any other condition that may

affect its safe operation.

2.

WARNING! TO PREVENT SERIOUS

INJURY: If the supply cord of this power

tool is damaged, it must be replaced only

by a qualified service technician.

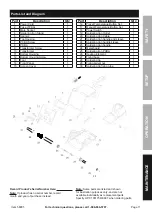

Change Tip

Note:

Replace the Soldering Tip if it cracks or becomes eroded.

1. Let Soldering Iron cool.

2. Remove Nut, Sleeve and Tip.

3. Push Tip into Sleeve, place Sleeve over heating

element, then secure in place with Nut.

Heating

Element

Tip

Sleeve

Nut

PLEASE READ THE FOLLOWING CAREFULLY

THE MANUFACTURER AND/OR DISTRIBUTOR HAS PROVIDED THE PARTS LIST AND ASSEMBLY DIAGRAM

IN THIS MANUAL AS A REFERENCE TOOL ONLY. NEITHER THE MANUFACTURER OR DISTRIBUTOR

MAKES ANY REPRESENTATION OR WARRANTY OF ANY KIND TO THE BUYER THAT HE OR SHE IS

QUALIFIED TO MAKE ANY REPAIRS TO THE PRODUCT, OR THAT HE OR SHE IS QUALIFIED TO REPLACE

ANY PARTS OF THE PRODUCT. IN FACT, THE MANUFACTURER AND/OR DISTRIBUTOR EXPRESSLY

STATES THAT ALL REPAIRS AND PARTS REPLACEMENTS SHOULD BE UNDERTAKEN BY CERTIFIED AND

LICENSED TECHNICIANS, AND NOT BY THE BUYER. THE BUYER ASSUMES ALL RISK AND LIABILITY

ARISING OUT OF HIS OR HER REPAIRS TO THE ORIGINAL PRODUCT OR REPLACEMENT PARTS

THERETO, OR ARISING OUT OF HIS OR HER INSTALLATION OF REPLACEMENT PARTS THERETO.